2101510 Rev. AG

Page 6–5

3)

Using the

Assembly instructions in

replace the analytical module assembly.

Totalflow recommends that a replacement analytical module

be installed at this point, and additional steps be performed

in a clean, lint free atmosphere.

The Totalflow repair department offers a range of services

for troubleshooting and repairing/replacing the non-

functioning parts. For more information regarding the repair

service, contact customer service:

USA: (800) 442-3097 or International: 1-918-338-4880

6.2.4

Processor Control Test

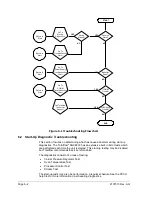

If Col 1 or Col 2 carrier pressure test failed, or the oven temperature test failed,

the following procedure will step the user through the troubleshooting process. On

occasion, these instructions may detour to other procedures, and when complete,

the user should return to these procedures to continue.

6.2.4.1

Description

These alarms are indicative of a lack of ability to control a function. If the failure is

either one or both of the column carrier pressure tests, it could be a missing or

failed gasket. If the failure is in the oven control temperature test, it could be

something as easy as a missing GC module cover or analytical module thermal

flask.

6.2.4.2

Instructions

1)

If the start-up diagnostics are being performed following the

disassembly/replacement of a module or spare part, insure that the unit is

completely reassembled, including the thermal flask and both the front and

rear end caps, and then re-start the diagnostics. If diagnostics again fail,

repeat disassembly steps and verify that all gaskets and connections are

tight and correctly installed. Otherwise, continue to the next step.

2)

If the start-up diagnostics are being performed from an initial startup, verify that

the analytical module is not loose inside the enclosure.

3)

Verify that the GC module is tight and that the cables are correctly installed and

not damaged.

4)

Reassemble the unit and restart diagnostics. If the unit continues to fail, replace

the entire analytical module and return to Totalflow for warranty

repair/replacement.

6.2.5

Stream Test

The stream flow diagnostics go through a series of tests, testing the stream

pressure at different conditions as listed below. Each column will display the

pressure results after that part of the test has completed. The status column will

reflect the current and final status of the tests.

The following procedure will step the user through the troubleshooting process.

On occasion, these instructions may detour the user to other procedures, and,

when complete, they should return to these procedures to continue.

During the stream test, streams with no gas pressure will fail

and will be disabled in the stream sequence. To enable

these streams, please click

Stream Setup

on the Analyzer

Operation screen.