8

9

1

1

OPTIONAL 3M™ ATTEST™ AUTO-READER 390G WEB APP

Web Browser Requirements

The Web Interface is designed to be viewed in Internet Explorer 8.0 or higher. Earlier

versions of Internet Explorer or other browsers may result in some web pages being

displayed in a less-than-optimum manner. For best results, switching to Internet Explorer

8.0 or higher is recommended. For full functionality, the use of an HTML5 compliant

browser with JavaScript enabled is recommended.

Connecting to the 3M™ Attest™ Auto-reader 390G Web App

To use the 3M™ Attest™ Auto-reader 390G Web App, the 3M™ Attest™ 390G

Auto-reader must be connected to the facility network using the supplied Ethernet

cable. Consult with your facility IT personnel for assistance with network connectivity.

Users may connect to the 3M™ Attest™ Auto-reader 390G Web App using a URL based

upon either the 3M™ Attest™ Auto-reader 390G serial number or the IP Address. To

view the 3M™ Attest™ Auto-reader 390G Web App from a wireless device such as a

mobile hand-held device or a computer on a sub-net different from that to which the

3M™ Attest™ Auto-reader 390G is connected, use the IP Address URL.

Note:

To access the 3M™ Attest™ Auto-reader 390G Web App within a secure network,

the PC or mobile device must have access to the secure network; options include

connecting via a network Ethernet cable, signing in to the facility’s wireless network, or

connecting via a virtual private network (VPN).

A. Serial number URL

1. Connect the supplied Ethernet cable from the 3M™ Attest™ Auto-reader 390G to an

Ethernet jack.

2. Depress the

button once to display the 3M™ Attest™ Auto-reader 390G 6-digit

serial number on the left side of the top row of text on the LCD display.

3. Enter http://attestxxxxxx where xxxxxx represents the unit’s serial number (e.g., http://

attest401008) from Step 2 in PC web browser address bar and press Go.

4. 3M™ Attest™ Auto-reader 390G Web App Status page will display on PC. For future

ease of use, add this page to your web browser “Favorites.”

B. IP Address URL

The 3M™ Attest™ Auto-reader 390G Web App may also be accessed using either a

dynamic or static IP address.

1. Dynamic IP Address

A dynamic IP address is assigned when the Ethernet cable is connected from the

3M™ Attest™ Auto-reader 390G to a live Ethernet jack.

Press and release the

button twice to display the 3M™ Attest™ Auto-reader 390G’s

dynamic IP address. Enter http://IPaddress (e.g. http://123.45.678.90) in the web browser

address bar of the PC or mobile hand-held device and press Enter. The 3M™ Attest™

Auto-reader 390G Web App Status page will display.

2. Static IP address

Some facility IT personnel may require devices connecting to the network to use a Static

IP address. If this is the case at your facility, contact the IT department to request a Static

IP address.

Record the static IP address provided by your facility IT department here: ___________.

You may wish to label the Ethernet jack with the assigned address. Enter

http://StaticIPaddress (e.g. http://111.22.333.44) in the web browser address bar on your

PC or mobile hand-held device and press Enter. The 3M™ Attest™ Auto-reader 390G

Web App Status page will display.

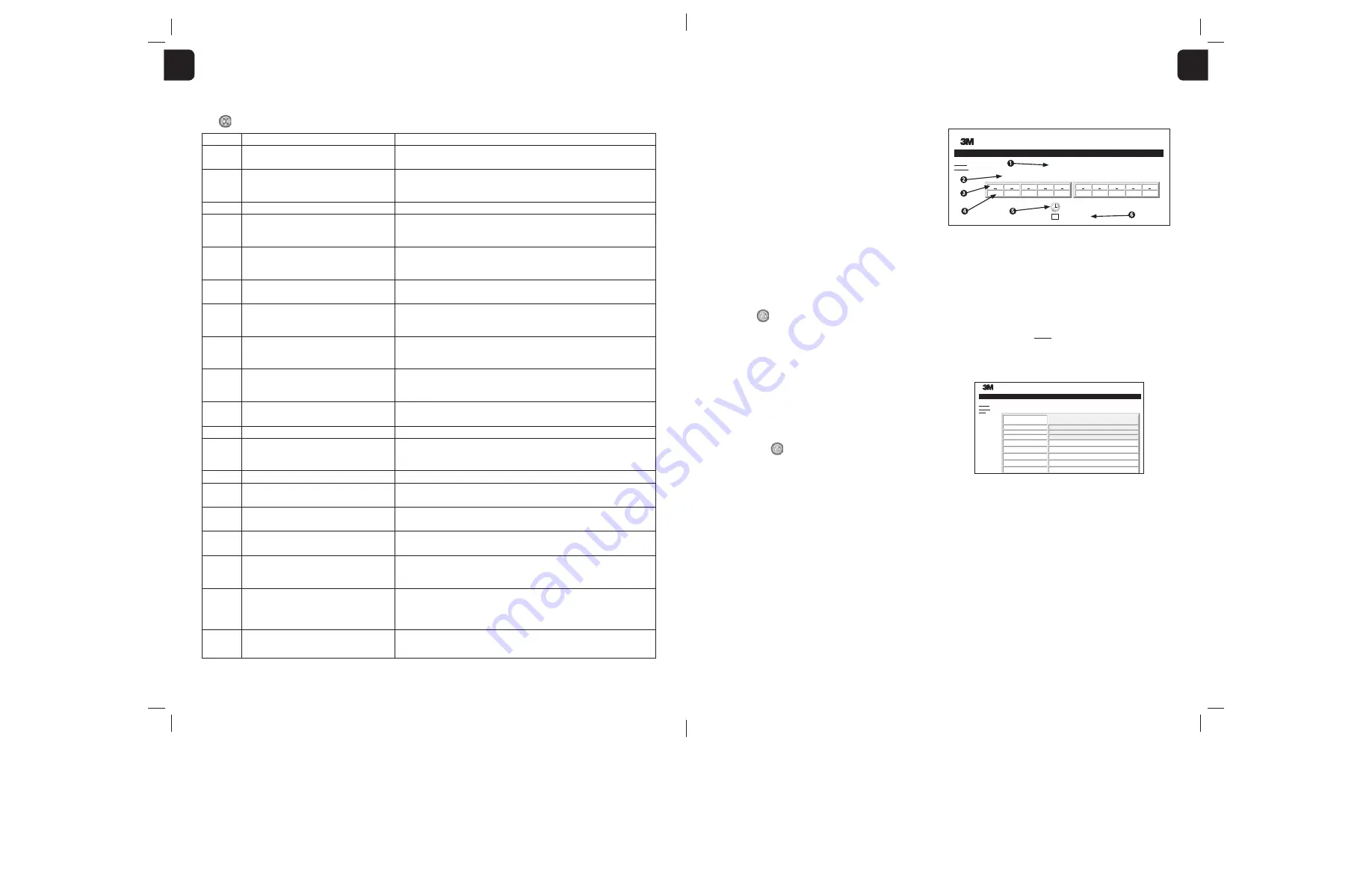

About the 3M™ Attest™ Auto-reader 390G Web App Pages

The 3M™ Attest™ Auto-reader 390G Web App includes four pages:

a) Status page

Status

History

3M™ Attest™ Auto-reader 390G

ATTEST 1294

ATTEST 1294

1

2

3

4

5

+

–

85

240

6

7

8

9

10

SN

100122

2012-10-31 12:32

1. User-entered nickname (optional)

2. Well Configuration (1-5 and 6-10)

3. Well Number

4. BI Result/Remaining Incubation Time

5. Date and Time

6. 3M™ Attest™ Auto-reader 390G Serial Number

The Status page provides a real-time representation of the 3M™ Attest™

Auto-reader 390G LCD panel display. The current date and time and 3M™ Attest™

Auto-reader 390G serial number are also indicated on this page. From this page, the user

may navigate to:

• the History page by clicking on History on the left of the screen.

• the Results Detail page by clicking on the well number of an occupied well (i.e., a well

that currently has an incubating BI). Clicking on an unoccupied well takes the user to

the History page.

b) Results Detail page

3M™ Attest™ Auto-reader 390G Results Detail

Status

History

Print

Result

Start Time

Well# and Configuration

390G Serial Number

Control?

BI Lot#

Load#

Sterilizer#

Technician

–

2012-10-29 11:08:04

#3 1294

100122

This page provides an individual record for an incubated BI. For complete documentation,

the user may print a hard copy and/or save the record as an electronic file.

Note 1:

The top four rows (highlighted in green) are populated automatically by the

3M™ Attest™ Auto-reader 390G and cannot be changed by the user. The remaining rows

are completed by the user to satisfy the documentation requirements of their facility.

Note 2:

The Results Detail page refreshes less frequently that the Status page. Until the BI

result is available, the Results Detail page displays remaining minutes of incubation in the

results field.

TROUBLESHOOTING GUIDE

In the event of an error code, unplug the 3M™ Attest™ Auto-reader 390G and plug it back in to initiate the self-diagnostic test. If error code re-occurs, call for repair or replacement.

The LCD display panel will indicate detected malfunctions by displaying a caution or error code under affected BI wells. The audible alarm, if active, sounds and the LCD display

backlight flashes to alert the user to all caution (except C1) and error codes. The alarm and backlight can be silenced and extinguished, respectively, by pressing the Buzzer Alarm OFF

button

. Note that disabling the audible alarm does not disable the flashing LCD display backlight. Refer to the following:

Code/Issue

Problem

Solution

C1

Unit Warm-up Caution

Incubation block not at temperature.

Allow a 30 minute warm-up after 3M™ Attest™ Auto-reader 390G is plugged in. (Note: 3M™ Attest™

Rapid Readout BI readings are disabled until incubator block reaches 37ºC +/- 2ºC).

C2

BI Removed from Well Caution

3M™ Attest™ Rapid Readout BI has been removed before

incubation is complete.

Replace 3M™ Attest™ Rapid Readout BI in proper well within 10 seconds to prevent loss of collected

data.

C4

Ambient Light Caution

Move 3M™ Attest™ Auto-reader 390G to reduced ambient light conditions.

E1

Temperature Control Error

This error will occur if system is no longer able to control

the temperature of the incubator block (37ºC +/- 2ºC).

Unplug the unit and plug it back in to clear error.

If error doesn’t clear, call for repair or replacement.

E3

Memory Error

3M™ Attest™ Auto-reader 390G unable to save/read data

from memory.

Unplug the unit and plug it back in to clear error.

If error doesn’t clear, call for repair or replacement.

E7

Communications Error

This error will occur if internal communications have failed.

Call for repair or replacement.

E8

LED Error

This error occurs for a specific well if the system detects

that a UV LED or Optics Detection circuit is not working.

Unplug the unit and plug it back in to clear error.

If error doesn’t clear, call for repair or replacement. Do not use affected incubation well.

E11

BI Inserted Incorrectly Error

Incubation time remaining will not display and fluorescent

readings are not taken.

Ensure BI is designed to be incubated and read in the 3M™ Attest™ Auto-reader 390G.

Ensure BI is fully inserted into incubation well.

E12

Power Failure Error

Power to Auto-reader was off for too long to provide valid

result for affected BI(s).

Ensure power supply connection to Auto-reader is secure.

E14

Ambient Light Error (occupied well)

Fluorescent result will not display.

Rely on optional visual pH color change result for BI in affected well. Move 3M™ Attest™

Auto-reader 390G to reduced ambient light conditions to avoid future occurrences.

Other

Unwanted alarm sounds when positive BI detected.

Disable alarm; refer to

3M™ Attest™ Auto-reader 390G Configuration

section for instructions.

Other

Alarm Sounds

3M™ Attest™ Rapid Readout Biological Indicator has been

removed from incubation/reader well prematurely.

Replace 3M™ Attest™ Rapid Readout Biological Indicator in incubation/reader well within 10 seconds

to prevent loss of data collected.

Other

LCD panel does not display properly.

Unplug the unit and plug it back in. If problem persists call for repair or replacement.

Other

Negative Control Vial

BI not properly activated/ media did not contact spore strip.

Ensure BI cap is closed, and glass ampoule is crushed. Tap BI until media flows to and wets spore strip

at bottom of BI.

Other

Negative Control Vial

Control vial was sterilized.

Check process indicator on BI label. Use a non-sterilized vial as a control.

Other

Unexplained Positive BI

Adhesive residue on vial.

Do not place tape or labels on vial.

Other

Unexplained Positive BI

Test vial is absorbing fluorescent residue from a chemical

indicator or tape.

Place the vial so it does not come in direct contact with chemical indicators or tape.

Other

3M™ Attest™ Auto-reader 390G will not enter

Configuration mode.

Pushbutton Configuration may be disabled on

3M™ Attest™ Auto-reader 390G Web App.

On 3M™ Attest™ Auto-reader 390G Web App Configuration Page, go to Pushbutton Configuration and

select the

Enable

radio button. Save changes to begin using new setting.

Other

3M™ Attest™ Auto-reader 390G LCD display flashes

and asterisks (***) and/or E11 and/or C4 codes appear on

display below unoccupied incubation wells.

Move 3M™ Attest™ Auto-reader 390G away from sunlight or sources of incandescent light.

Rendered on 9/12/2013 10:34:26 AM

Page 6

34871202866.pdf