4-10

Operating the Converter

590+ Series DC Digital Converter

Caution

During the following set-up instructions, be ready to STOP the converter should the

motor try to overspeed.

Step 12

Set the Speed Setpoints so that the value of the SPEED

SETPOINT is about 5%, 0.5V at setpoint input (terminal A8).

Perform the next operation with ARM VOLTS FBK selected for

the SPEED FBK SELECT parameter (because it is hard-wired

and therefore the sign will be correct). Select it now.

Slowly increase the MAIN CURR.LIMIT parameter up to a maximum

of about 20%. The motor should begin to rotate if all connections are

made correctly. The motor speed will settle at about 5% of full speed

if the motor is unloaded. Check the feedback from the Tachometer or

Encoder using the appropriate Diagnostic menu.

Now stop the drive. Re-instate your selection for the SPEED FBK SELECT parameter (if

other than ARM VOLTS FBK) and perform the same test again.

If the test was successful perform a PARAMETER SAVE and go to 14. If just direction of

rotation is wrong, go to 13, otherwise check as below.

If 5% speed (approx.) is exceeded and the motor continues to

accelerate a reversed connection is implied, decrease the MAIN

CURR.LIMIT parameter to zero.

Step 12.1

Reversed Connections - Analog Tachogenerator:

Open the main contactor and switch off all supplies, then correct the connections.

If the motor is turning in the correct direction, reverse the tachogenerator

connections only.

If the motor is turning in the wrong direction, reverse the field connections only.

Step

12.2

Reversed Connections - MICROTACH/Encoder:

Open the main contactor.

If the motor is turning in the right direction, change over

the ENCODER SIGN parameter.

If the motor is turning in the wrong direction, switch off all

supplies then reverse the field connections only.

Re-connect the supplies if disconnected and repeat the test from the beginning.

If the motor still runs out of control, check the tachogenerator and the wiring continuity. In the

case of the MICROTACH there are two LED's on the MICROTACH option board, both LED's

should be ON indicating healthy operation of the wiring and tacho. If in doubt about the

operation of the tachogenerator either Analog or MICROTACH during this test, monitor

terminal A7 with respect to signal ground on a meter. This will show if a feedback is present.

Note:

If the drive trips on speed feedback alarm with

tachogenerator feedback of the correct polarity, check the

armature voltage calibration.

Check the SPEED FBK SELECT. This could be set incorrectly

allowing the drive to run open loop.

If the motor does not turn at all when the MAIN CURR.LIMIT is

increased to 20%, check the CURRENT FEEDBACK parameter to

verify that current is flowing into the armature. If no current is

flowing, switch off and check the armature connections.

Is the motor connected to the drive?

Verify that calibration has been carried out correctly.

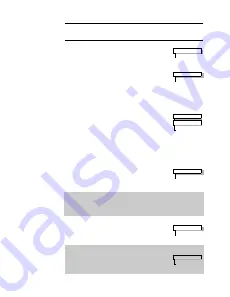

MMI Menu Map

1

DIAGNOSTICS

SPEED SETPOINT

MMI Menu Map

1

CONFIGURE DRIVE

SPEED FBK SELECT

MMI Menu Map

1

SETUP PARAMETERS

2

CURRENT LOOP

MAIN CURR.LIMIT

MMI Menu Map

1

CONFIGURE DRIVE

ENCODER SIGN

MMI Menu Map

1

CONFIGURE DRIVE

SPEED FBK SELECT

MMI Menu Map

1

DIAGNOSTICS

CURRENT FEEDBACK