Programming Your Application

6-91

590+ Series DC Digital Converter

TENS+COMP CALC.

This block provides additional torque to

compensate for static and dynamic friction,

as well as the load inertia.

Add these losses to the diameter-scaled tension

demand to produce a compensated torque

demand for open loop winder applications.

The inputs to this block are DIAMETER from

the DIAMETER CALC. function block, TOT.

TENS. DEMAND from the TAPER CALC.

function block, and SPEED FEEDBACK from

the SPEED LOOP function block.

You should output TENS+COMP to TORQUE

DEMAND (Tag 432) in the TORQUE CALC. function block for open loop winder

applications.

Static and Dynamic Frictional Losses

Static and dynamic friction are due to gearbox resistance and mechanical binding in the winder

spindle and motor bearings. Both absorb motor output torque and require compensation to

maintain accurate winder tension.

Static friction, or "stiction", is a constant offset most noticeable at or near zero speed. The

compensation torque required to overcome static friction is fixed over an entire operating

speed range. You can ignore "stiction" for winders which do not normally operate at zero

speeds.

Dynamic friction results from friction

losses within the drive train, which

includes gearboxes and chain belting

linkages. The oil viscosity in

gearboxes and windage losses in the

motor armature fans also contribute to

dynamic frictional losses.

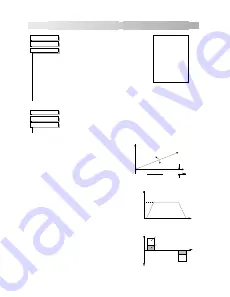

The effects of static and dynamic

friction are shown opposite.

Inertia Compensation

Many winders need inertia compensation

to add or subtract torque during

acceleration and deceleration to maintain

constant tension, especially at large roll

diameters. Without compensation, the

tension holding capability of open loop

winders diminishes during speed changes

causing tension sag.

The inertia compensation characteristics

is shown opposite.

For winder applications, inertia

compensation is split into two

components:

1.

Fixed inertia compensation for the

fixed motor, transmission and load

components.

2.

Variable inertia compensation for the

changing roll inertia. This is

especially necessary for high

diameter build unwinds and winders.

Tension & Comp

TENS+COMP [478]

–

0

INERTIA COMP O/P

[485]

–

0.00 %

0.00 %

–

[487] STATIC COMP

0.00 %

–

[488] DYNAMIC COMP

ENABLED

–

[489] REWIND

0.00 %

–

[479] FIX. INERTIA COMP

0.00 %

–

[480] VAR. INERTIA COMP

100.00 %

–

[481] ROLL WIDTH/MASS

0.00 %

–

[498] LINE SPEED SPT

10

–

[482] FILTER T.C.

10.00

–

[483] RATE CAL

0.00 %

–

[484] NORMALISED dv/dt

1.0000

–

[486] TENSION SCALER

MMI Menu Map

1

SETUP PARAMETERS

2

SPECIAL BLOCKS

3

TENS+COMP CALC.

STATIC COMP

DYNAMIC COMP

REWIND

FIX.INERTIA COMP

VAR.INERTIA COMP

ROLL WIDTH/MASS

LINE SPEED SPT

FILTER T.C.

RATE CAL

NORMALISED dv/dt

INERTIA COMP O/P

TENSION SCALER

MMI Menu Map

1

SYSTEM

2

CONFIGURE I/O

3

BLOCK DIAGRAM

TENS+COMP CALC.

Motor Speed

Static

Dynamic

Torque

(Armature Current)

Compensation

Compensation

Speed

Line Speed

100%

Time

deceleration

acceleration

Forward Torque

Time

large diameter roll

small diameter roll

(positive armature current)

Reverse Torque

(negative armature current)