Figure 9-8

Incremental dimensions

The position specifications for points P1 to P4 in incremental dimensions are as follows:

P1: X12.5 Z-7.5 (relative to the zero point)

P2: X7.5 Z-7.5 (relative to P1)

P3:X0 Z-10 (relative to P2)

P4: X10 Z-10 (relative to P3)

9.4.4

Polar coordinates

You can specify positions using right-angled coordinates or polar coordinates.

If a point in a workpiece drawing is defined by a value for each coordinate axis, you can easily

input the position into the parameter screen form using right-angled coordinates. For

workpieces that are dimensioned with arcs or angular data, it is often easier if you input the

positions using polar coordinates.

You can only program polar coordinates for the functions "Straight circle" and "Contour milling."

The point from which dimensioning starts in polar coordinates is called the "pole".

3ROH

r

r

r

3

3

3

=

;

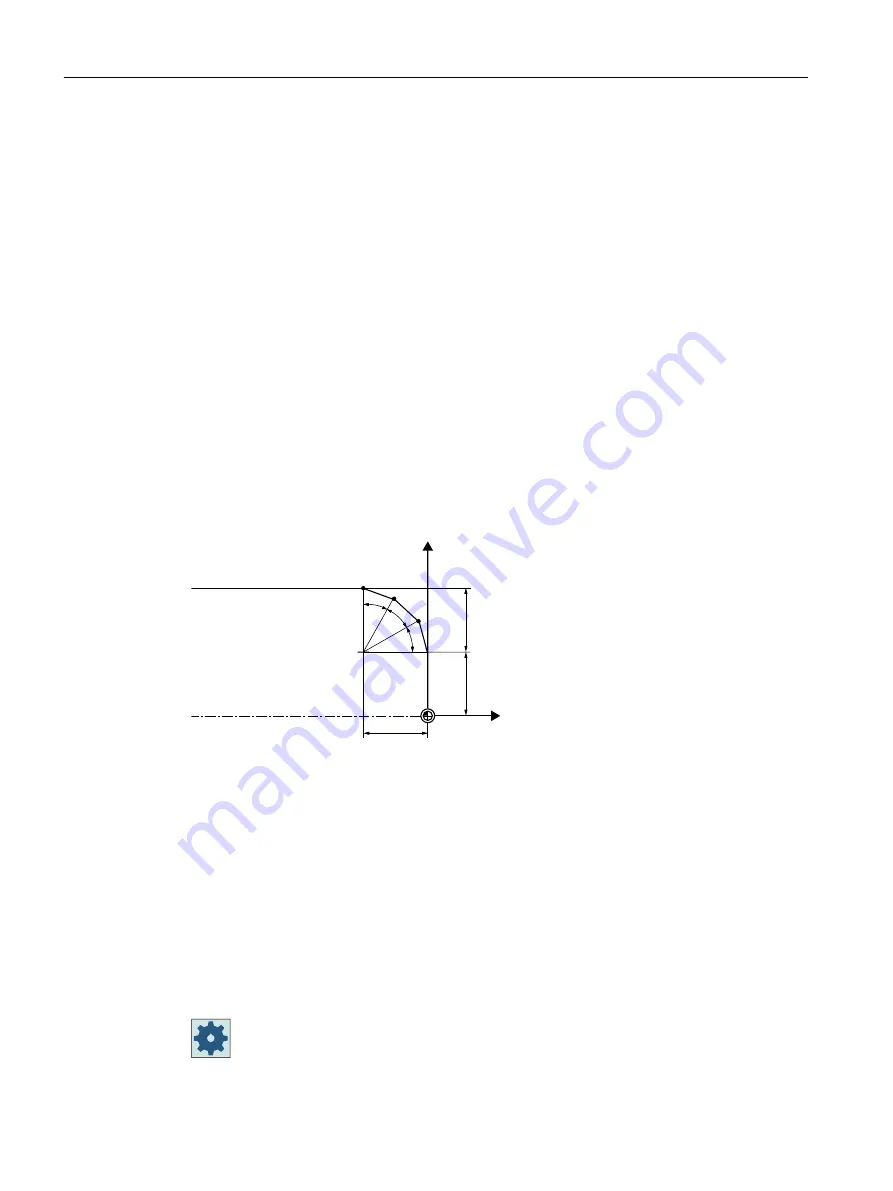

Figure 9-9

Polar coordinates

The position specifications for the pole and points P1 to P3 in polar coordinates are:

Pole: X30 Z30 (relative to the zero point)

P1: L30 α30° (relative to the pole)

P2: L30 α60° (relative to the pole)

P3: L30 α90° (relative to the pole)

9.4.5

Clamping the spindle

The "Clamp spindle" function must be set up by the machine manufacturer.

Machine manufacturer

Please refer to the machine manufacturer's specifications.

Creating a ShopTurn program

9.4 Fundamentals

Turning

296

Operating Manual, 06/2019, A5E44903486B AB

Содержание SINUMERIK 840D sl

Страница 8: ...Preface Turning 8 Operating Manual 06 2019 A5E44903486B AB ...

Страница 70: ...Introduction 2 4 User interface Turning 70 Operating Manual 06 2019 A5E44903486B AB ...

Страница 274: ... Creating a G code program 8 8 Selection of the cycles via softkey Turning 274 Operating Manual 06 2019 A5E44903486B AB ...

Страница 275: ... Creating a G code program 8 8 Selection of the cycles via softkey Turning Operating Manual 06 2019 A5E44903486B AB 275 ...

Страница 282: ...Creating a G code program 8 10 Measuring cycle support Turning 282 Operating Manual 06 2019 A5E44903486B AB ...

Страница 344: ...Creating a ShopTurn program 9 19 Example Standard machining Turning 344 Operating Manual 06 2019 A5E44903486B AB ...

Страница 716: ...Collision avoidance 12 2 Set collision avoidance Turning 716 Operating Manual 06 2019 A5E44903486B AB ...

Страница 774: ...Tool management 13 15 Working with multitool Turning 774 Operating Manual 06 2019 A5E44903486B AB ...

Страница 834: ...Managing programs 14 19 RS 232 C Turning 834 Operating Manual 06 2019 A5E44903486B AB ...

Страница 856: ...Alarm error and system messages 15 9 Remote diagnostics Turning 856 Operating Manual 06 2019 A5E44903486B AB ...

Страница 892: ...Working with two tool carriers 18 2 Measure tool Turning 892 Operating Manual 06 2019 A5E44903486B AB ...

Страница 912: ...HT 8 840D sl only 20 5 Calibrating the touch panel Turning 912 Operating Manual 06 2019 A5E44903486B AB ...

Страница 927: ...Appendix A A 1 840D sl 828D documentation overview Turning Operating Manual 06 2019 A5E44903486B AB 927 ...