Communications

configuring

System- and communication configuring D7-SYS - SIMADYN D

3-165

Edition 12.2003

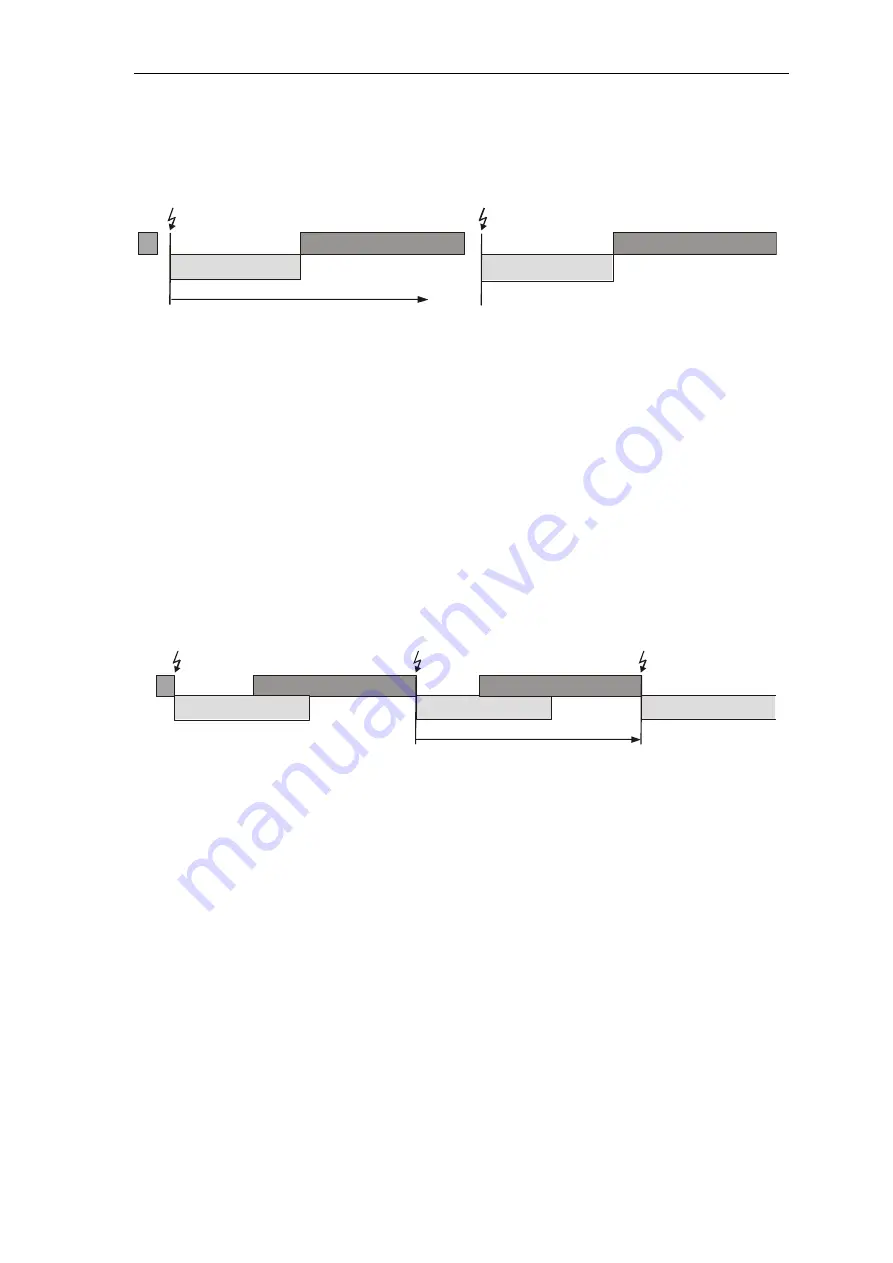

In the

timer mode

(Mode 2), data is directly output after calculation in an

interrupt task Ix which assigns the processing of the SIMOLINK blocks a

higher priority.

SIMOLINK cycle

SIMOLINK cycle

Timer interrupt

Interrupt task Ix

Timer interrupt

Processing time of the

SIMOLINK blocks

Processing time of the

SIMOLINK blocks

Fig. 3-59

Timer-mode (Mode 2)

In these non-synchronous SL-master modes, which exhibit jitter, the

coupled drives cannot be operated with position synchronism if the SYNC

telegram is sent in the time intervals which depend on the actual

configuring. This allows the fastest possible data transfer between SL

master (Mode 1 or 2) and the slave (Mode 0).

The

slave mode

(Mode 0) is used to read and evaluate the bus data

transfer in a drive ring, for e.g. monitoring and diagnostic purposes.

With each received SYNC telegram, the SIMOLINK module initiates that

the configured interrupt task Ix is processed. If it is used as the receive

section for fast data transfer between SL master and slave, all of the

telegrams can be read and processed. Furthermore, it is possible to write

a max. 8 telegrams, in order to, for example, transfer signals to the SL

master.

SIMOLINK cycle

Processing time of the

SIMOLINK blocks

Processing time of the

SIMOLINK blocks

SIMOLINK cycle

Processing time of the

SIMOLINK blocks

Interrupt task Ix

SYNC telegram

SYNC telegram

SYNC telegram

Fig. 3-60

Slave mode (Mode 0)

In order to send data between two automation systems via SIMOLINK,

which exceeds the amount of data using 8 telegrams, two independent

SIMOLINK rings are required. This means that every node can be

configured once as SL master to send in one ring and as slave to receive

in the other ring. This technique is used, for example, to achieve

•

synchronized processing and

•

extremely fast data transfer

between two SIMATIC FM 458 modules each with two EXM 448-1

expansion modules.

Reading telegrams,

synchronous

Coupling two

automation

systems