ENGLISH

SVENSKA

37

ITALIANO

4.0 MANUTENZIONE

Sono di seguito elencate le varie opera-

zioni di manutenzione da eseguirsi con

periodicità ed una tabella di Manutenzio-

ne (da non trascurare) in cui sono eviden-

ziate schematicamente operazioni, punti,

e periodi di controllo.

Il minor costo di esercizio ed una lunga

durata della macchina dipendono, tra l’al-

tro, dalla metodica e costante osservanza

di tali norme.

CAUTELA

I tempi di intervento elencati in questo

manuale hanno solo carattere infor-

mativo e sono relativi a condizioni

normali di impiego, possono pertanto

subire variazioni in relazione al genere

di servizio, ambiente più o meno pol-

veroso, fattori stagionali, ecc.

Nel caso di condizioni più gravose di

servizio, gli interventi di manutenzione

vanno logicamente incrementati.

Tutte le operazioni devono essere ese-

guite da personale esperto, munito di

adeguate protezioni (DPI), in ambiente

pulito e non polveroso.

Tutte le operazioni di manutenzione

devono essere eseguite tassativa-

mente con attrezzatura agganciata

al trattore, freno di stazionamento

azionato, motore spento, chiave di-

sinserita ed attrezzatura appoggiata

al suolo stabilmente a terra.

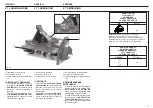

- Prima di iniettare il grasso lubrifi -

cante negli ingrassatori, è necessa-

rio pulire con cura gli ingrassatori

stessi per impedire che il fango, la

polvere o corpi estranei si mescoli-

no con il grasso, facendo diminuire,

o addirittura annullare, l’effetto della

lubrifi cazione.

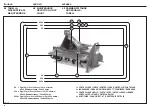

- Verifi care che non vi siano perdite

d’olio dalle tubazioni idrauliche,

altrimenti sostituirle.

- Nell’eseguire il ripristino o il cambio

olio, è consigliabile usare lo stesso

tipo di olio usato precedentemen-

te.

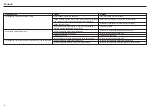

4.0 MAINTENANCE

The various routine servicing operations

required are listed below along with a

Maintenance table (which should be

complied with) that briefly illustrates

the operations, points and inspection

frequencies.

Lower running costs and longer machine

life depend on constant and methodical

compliance with these operations.

CAUTION

The given frequencies are indicative

and refer to normal conditions of use.

They may therefore be subject to vari-

ations in relation to the type of service,

a more or less dusty environment,

seasonal factors, etc.

In the case of heavy-duty conditions,

the maintenance operations should

obviously be more frequent.

All operations must be carried out by

expert personnel,wearing the proper

safety clothing in a clean, not dusty

environment.

All maintenance operations must be

strictly carried out with the implement

coupled to the tractor, hand brake

engaged, engine off, ignition key

removed, and implement lying fi rmly

on the fl oor.

- Before injecting grease into the

lubricators, the greasing points

must be thoroughly cleaned to

prevent mud, dust or foreign bod-

ies from mixing with the lubricant,

thus reducing or even annulling its

lubricating effect.

- Verify that there aren’t any oil leak-

ages from the hydraulic pipes,

otherwise replace them.

- When topping up or changing the

lubricant, always ensure that the

oil is of the same type as that used

previously.

4.0 UNDERHÅLL

Nedan räknas de olika underhållsmo-

menten upp som ska utföras regelbundet

följt av en Underhållstabell (som ej får

försummas) där moment, punkter och

kontrollperioder har schemalagts.

För låga driftskostnader och lång hållbar-

het ska dessa underhållsmoment följas

konstant och metodiskt.

VAR FÖRSIKTIG

De angivna underhållsintervallen är

indikativa och hänför sig till normala

användarförhållanden. De kan därför

variera med avseende på typen av

service, mer eller mindre dammiga

omgivningar, säsongsartade faktorer

osv.

Vid förhållanden med stor belastning,

måste naturligtvis underhåll utföras

oftare.

Alla underhållsmoment måste utföras

av expertkunnig personal, som använ-

der lämplig skyddsutrustning, i en ren

och dammfri omgivning.

Alla underhållsmoment måste ut-

föras med maskinen tillkopplad till

traktorn, åtdragen parkeringsbroms,

avstängd motor, utdragen startnyckel

och utrustningen ska ligga stadigt på

marken.

- Innan ni sprutar in smörjfett i smör-

janordningarna, ska de rengöras

noggrant för att förhindra att lera,

damm eller främmande partiklar

blandas med smörjfettet, eftersom

det skulle kunna reducera eller till

och med annullera smörjeffekten.

- Kontrollera att det inte fi nns några

oljeläckor i de hydrauliska rören, byt

i så fall ut dem.

- Vi rekommenderar att ni använder

samma typ av olja som tidigare vid

påfyllning eller byte av olja.