ENGLISH

SVENSKA

45

ITALIANO

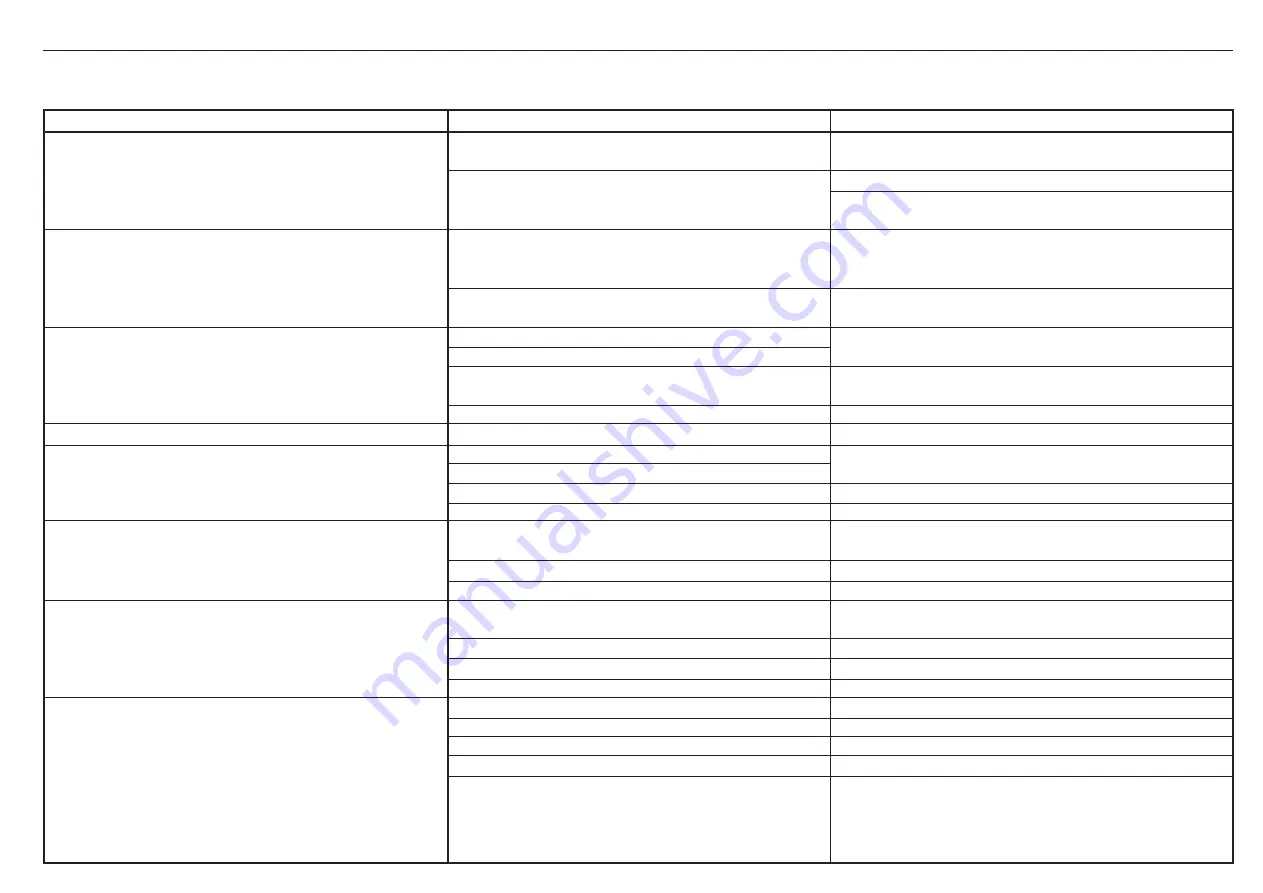

Inconveniences

Causes

Remedies

4.9 INCONVENIENCES,

CAUSES

AND

REMEDIES

Noise from the transmission near the lifting devices.

Noise from the rotary cultivator as it works.

Power draw too high on dry ground.

Too much soil thrown up from the rear part of the rotary cultivator.

Power draw too high on wet ground.

Soil crumbled to an excessive extent.

Soil broken into excessively large clods.

Rotor clogged.

Unsuitable lifting couplings.

Lifting height too high.

The rotary cultivator tilts to far forward or backwards as it

works.

Rotary cultivator with insuffi cient side stability.

Too much soil worked.

Soil working too deep.

Worn cultivator blades.

Rotor speed too fast (versions with gearbox).

Levelling plate incorrectly positioned.

Too much soil worked.

Soil working too deep.

Levelling plate clogged.

Rotor speed too fast (versions with gearbox).

Levelling plate closed to an excessive extent.

Ground speed too low.

Rotor speed too fast (versions with gearbox).

Levelling plate open to an excessive extent.

Ground speed too high.

Soil too wet.

Low rotor speed (versions with gearbox).

Soil too wet.

Levelling plate closed to an excessive extent.

Ground speed too high.

The cultivator blades retain the worked soil.

Very tall grass and/or excessively long plant cuttings.

Set the third point hitch parallel to the lower lifting links.

Limit the lifting travel.

If the fault persists, disengage the PTO as the machine starts to lift.

Lengthen or shorten the third point hitch so that the upper surface of

the rotary cultivator is parallel to the ground worked (the PTO connec-

tions of the tractor and rotary cultivator must be parallel).

Ensure that the rotary cultivator remains stable by means of the rods

of the lower lift links.

Reduce the work depth by adjusting the rotary cultivator’s depth

skids.

Replace the complete set of cultivator blades to ensure that the rotor

is stable.

Reduce the speed of the gearbox.

Change the position of the levelling plate.

Reduce the work depth by adjusting the rotary cultivator’s depth

skids.

Raise the levelling plate to make the soil shift more easily.

Reduce the speed of the gearbox.

Raise the levelling plate to prevent the clods from being broken up

too much.

Increase the ground speed.

Reduce the speed of the gearbox.

Lower the levelling plate to break up the soil clods to a greater ex-

tent.

Reduce the ground speed.

Do not work soil that is too wet.

Increase the speed of the gearbox.

Do not work soil that is too wet.

Raise the levelling plate.

Reduce the ground speed.

Reduce the number of cultivator blades from 6 to 4 for each rotor fl ange.

Do not work when the grass is too high or the plant cuttings are very

long. If necessary, remove the clogged plants from the supports at the

sides of the rotor to prevent them from overheating.