7-50

Removal and Installation

January 24, 2017

Option work implement and accessory system

CLG835H

Option work implement and accessory system

Option of work implement system

Work implement system has standard boom and extension boom for selection, please refer to "Work

Implement Parameters", and select according to practical use and needs of working conditions.

Option of accessory system

Procedure of selecting and assembling the bucket:

1. Identify the target condition.

2. According to working condition, select suitable bucket type according to Attached Table 1 - Bucket

Classification Table.

3. Look up the Attached Table 3 Bulk Density of Bulk Materials to obtain the corresponding density of

material of working condition.

4. According to material density value, select corresponding bucket capacity by checking Attached

Table 2 - Recommendation List for Bucket Selection.

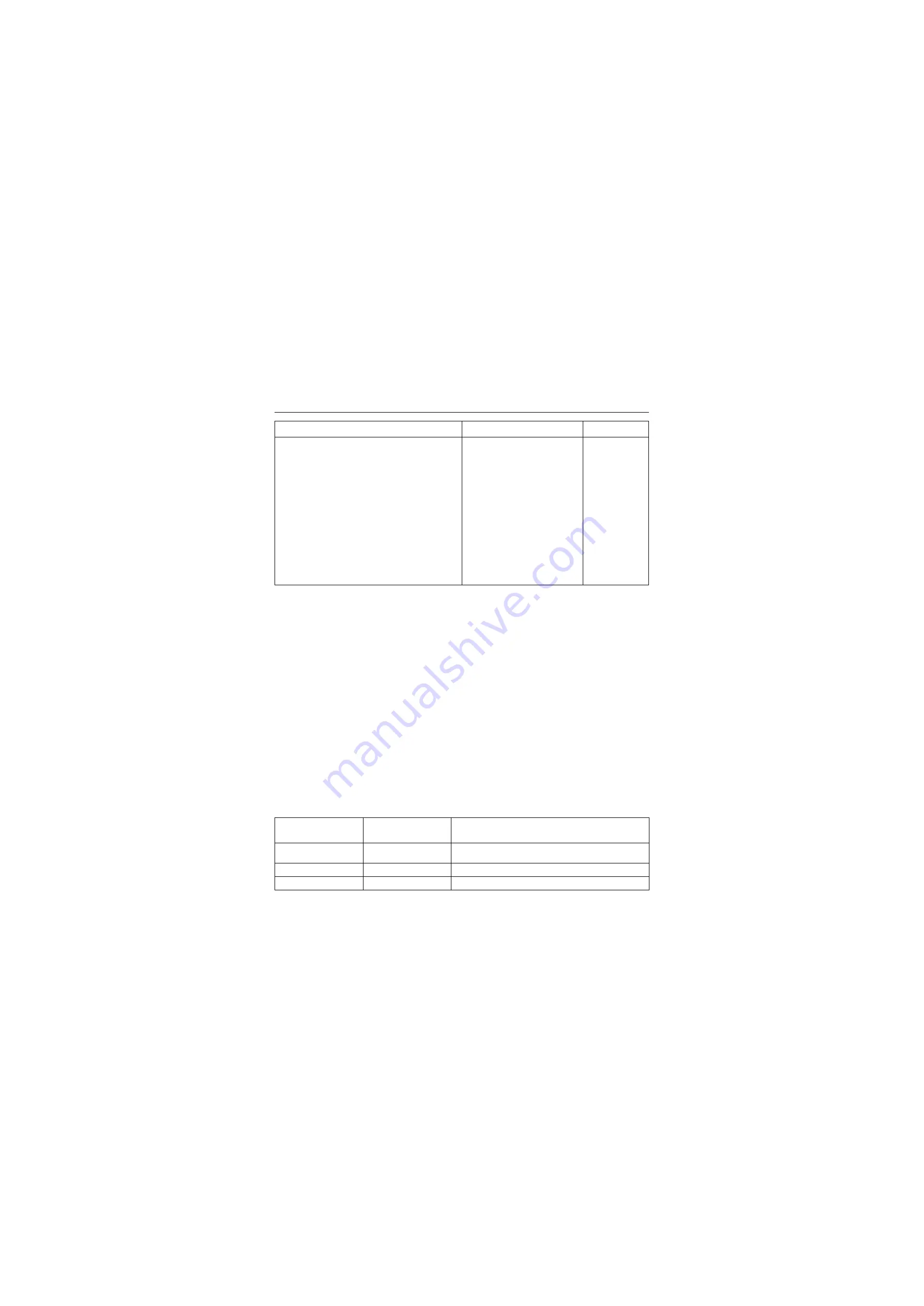

Attached table 1: The classification table of bucket

4. Replace the movable blade:

1) Remove nut (3), washer (4)

and bolt (5) fixing movable

blade.

2) Take down movable blade

(No.11).

3) Place new movable blade

(11) on corresponding posi-

tion of cutting edge.

4) Align the mounting holes of

movable blade and cutting

edge, and install new bolt

(5), washer (4) and nut (3).

50# Socket

wrench

Figures

Operation instruction

Tools

Types of Buckets

Acceptable range of

density

Main purposes

GP bucket

1.2~1.9t/m

3

Applicable to various working conditions, provided with excel-

lent insertion performance and material holding performance.

Light loading hopper

0.8~1.25t/m

3

It is mainly used in condition of loose light load material

Rock bucket

1.8~2.0t/m

3

It is under heavy load condition, such as rocks, etc.

Содержание CLG835H

Страница 2: ......

Страница 4: ...Contents January 24 2017 CLG835H...

Страница 6: ...1 2 General Information January 24 2017 CLG835H...

Страница 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Страница 154: ...2 116 Fault Diagnosis and Troubleshooting January 24 2017 Common fault code and troubleshooting CLG835H...

Страница 156: ...3 2 Power Train System January 24 2017 CLG835H...

Страница 214: ...3 2 Power Train System January 24 2017 CLG835H...

Страница 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Страница 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Страница 296: ...4 24 Structure Function Principle January 24 2017 Work hydraulic system CLG835H Exploded view of control valve P18H00016...

Страница 297: ...4 25 January 24 2017 Structure Function Principle CLG835H Work hydraulic system Exploded view of control valve P18H00017...

Страница 308: ...4 36 Structure Function Principle January 24 2017 Work hydraulic system CLG835H Outline diagram of pilot valve P18H00027...

Страница 506: ...4 234 Fault Diagnosis and Troubleshooting January 24 2017 Common troubleshooting for brake system CLG835H...

Страница 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Страница 606: ...6 56 Removal and Installation January 24 2017 Removal and installation of the engine hood torque mechanism CLG835H...

Страница 608: ...7 2 Structure January 24 2017 CLG835H...

Страница 662: ...8 4 Electrical System January 24 2017 CLG835H...

Страница 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...

Страница 737: ...8 79 January 24 2017 Structure Function Principle CLG835H Audio system Audio system Audio system principle P18E00138...

Страница 756: ...9 2 Appendix January 24 2017 CLG835H...

Страница 757: ...9 3 January 24 2017 Schematic Diagram of Hydraulic System CLG835H Schematic Diagram of Hydraulic System...

Страница 758: ...9 4 January 24 2017 Schematic Diagram of Brake System CLG835H Schematic Diagram of Brake System...