Scanner Maintenance

Liquid Cooling Systems

p/n 6510020208

10/18/07

9-53

become plugged. If this occurs, perform one of these

procedures:

•

To manually clean the exchanger unit, remove the bonnet

from the unit and clean the tubes with a nylon brush.

•

To chemically clean the exchanger unit, circulate a liquid

acid type of cleaner through the mill water supply side of

the unit. Make certain that the control valve is fully open by

pouring hot water into the expansion tank, or by manually

opening the valve by placing a blade screwdriver under the

spring cap on the valve and lifting up.

9.10.1.3.

Maintaining the chiller (closed loop)

Procedures for maintaining a Honeywell chiller are supplied with the

chiller documentation. For maintenance procedures for a non-Honeywell

chiller, refer to the documentation provided by the chiller manufacturer.

To prolong the anti-rust, corrosion, scale, and heat transfer properties of

the coolant mixture, an additive 6530220027 EXTENDER, COOLANT HD

ANTIFREEZE is required after three years of operation. The additive is to

be added in a ratio of 45:1 with the capacity of the cooling system. The

cooling system must be flushed and filled after five years of operation.

9.10.1.4.

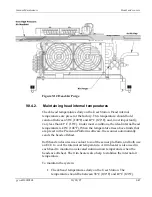

Maintaining the PMP enclosure cooling

These tasks apply to the optional heat exchanger available for the 4022-31

remote PMP cabinet. These items need to be done to maintain the PMP

cooling system:

•

Check the heat exchanger for leaking coolant as per the

maintenance schedule suggested in Chapter 8. To prolong the anti-

rust, corrosion, scale, and heat transfer properties of the coolant

mixture, an additive 6530220027 EXTENDER, COOLANT HD

ANTIFREEZE is required after three years of operation. The

additive is to be added in a ratio of 45:1 with the capacity of the

cooling system. The cooling system must be flushed and filled after

five years of operation.

•

Check the airflow through the heat exchanger fans as per the

maintenance schedule suggested in Chapter 8.

•

Replace the solenoid valve on the heat exchanger every year.

Содержание 4022

Страница 1: ...Precision Platform 4022 Scanner System Manual 6510020208 ...

Страница 2: ......

Страница 3: ...Precision Platform 4022 Scanner October 2007 ...

Страница 22: ......

Страница 72: ......

Страница 94: ......

Страница 126: ......

Страница 162: ......

Страница 170: ......

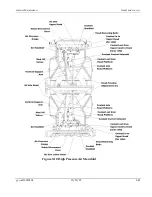

Страница 221: ...Scanner Maintenance Heads and sensors Figure 9 10 High Pressure Air Manifold p n 6510020208 10 18 07 9 45 ...

Страница 234: ......

Страница 239: ...Glossary p n 6510020208 10 18 07 11 5 VIO Virtual Input Output ...