Scanner Maintenance

Motor and Encoder

6.

Run a profile correction for the sensors that need it (Refer to

Da

Vinci System Installation and Setup Manual

, p/n 46018200).

7.

Order items used from the spares inventory.

8.

Record maintenance information in the scanner logbook.

9.8. Motor and Encoder

WARNING

:

To perform any maintenance, troubleshooting, or replacement of

components, ensure that power is disabled at the breaker.

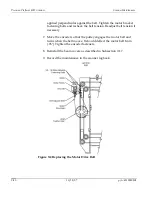

9.8.1. Replacing the head position encoder

1.

Disconnect the encoder cable from terminal strip

TS2

.

2.

Remove the bolts that hold the encoder bracket.

3.

Remove the old encoder from the bracket and install the new

encoder.

4.

Reinstall the encoder bracket.

5.

Move the encoder so that the pulley teeth engage the motor belt

and the pulley turns when the belt moves. It should deflect the

motor belt 1mm (.03in). Tighten the encoder fasteners.

9.8.2. Inspect/clean motor

If the motor is dusty, blow clean with compressed air. If there is extensive

noise from the motor bearing the motor should be replaced.

9.8.3. Replace AC motor

1.

Loosen the encoder and slide it away from the motor belt.

2.

Loosen the motor bracket attachment bolts.

p/n 6510020208

10/18/07

9-33

Содержание 4022

Страница 1: ...Precision Platform 4022 Scanner System Manual 6510020208 ...

Страница 2: ......

Страница 3: ...Precision Platform 4022 Scanner October 2007 ...

Страница 22: ......

Страница 72: ......

Страница 94: ......

Страница 126: ......

Страница 162: ......

Страница 170: ......

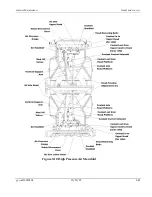

Страница 221: ...Scanner Maintenance Heads and sensors Figure 9 10 High Pressure Air Manifold p n 6510020208 10 18 07 9 45 ...

Страница 234: ......

Страница 239: ...Glossary p n 6510020208 10 18 07 11 5 VIO Virtual Input Output ...