94

ADL500 • Quick installation guide - Specifications and connection

The brake fault alarm function envisages signals that are normally asserted. If the wiring is functionally inverted, simply

negate the corresponding digital inputs in the ADL500

configuration.

To configure the brake fault alarm function, proceed as follows:

1. In the SAFETY menu , change the setting of parameter 11252

Brake Fbk A3 Sel

(default

Null

) and select the digi-

tal input corresponding to the second brake feedback signal If

Brake Fbk A3 Sel

is set to a value other than

Null

,

the brake fault alarm function is automatically enabled.

2. Next select the digital input corresponding to the first brake feedback signal in parameter 11236

Brake fbk src

(menu LIFT IN).

The brake fault function is enabled.

The installer in charge of the system must test the function each time it is

activated or modified, following the brake fault test procedure.

•

Resetting the brake fault alarm

1. Open the LIFT ALARM menu and check the setting of parameter 11204

Brake activity

= Disable.

2. In the SAFETY menu, select parameter 11268

Reset Brake Alarm

(default 0).

3. The system asks for a code, enter release code 5313.

4. Check again to see whether the

Brake Alarm

has been reset.

•

Disabling the brake fault alarm

1. In the SAFETY menu, change the setting of parameter 11252

Brake Fbk A3 Sel

to

Null

The brake fault alarm func-

tion is disabled.

2. If the new configuration does not manage any brake feedback signals, change the setting of parameter 11236

Brake Fbk Sel

(menu LIFT IN)

to [3708]

Brake cont mon

.

•

Brake fault alarm test procedure

Proceed as follows:

1. Disconnect the wire connecting the first brake feedback signal to the relative digital input.

2. Try re-starting from the floor with the feedback signal disconnected. If the lift car does not move (correct behaviour),

proceed to step 3. If the lift car moves, the alarm is not working properly. Check the various parts of the system.

3. If the brake fault alarm is connected, reset it and proceed to step 4. If the alarm is not connection, re-check the vari-

ous parts of the system.

4. Repeat steps 1, 2 and 3, disconnecting the second brake feedback signal from the corresponding input.

If the procedure is successful, the brake fault alarm will function properly.

A.4.3 Maintenance of the brake fault alarm function

The installer must repeat the brake fault alarm test procedure during periodical inspections and whenever messages

concerning the brake unit are displayed.

The installer must check the alarm log each time for any faults

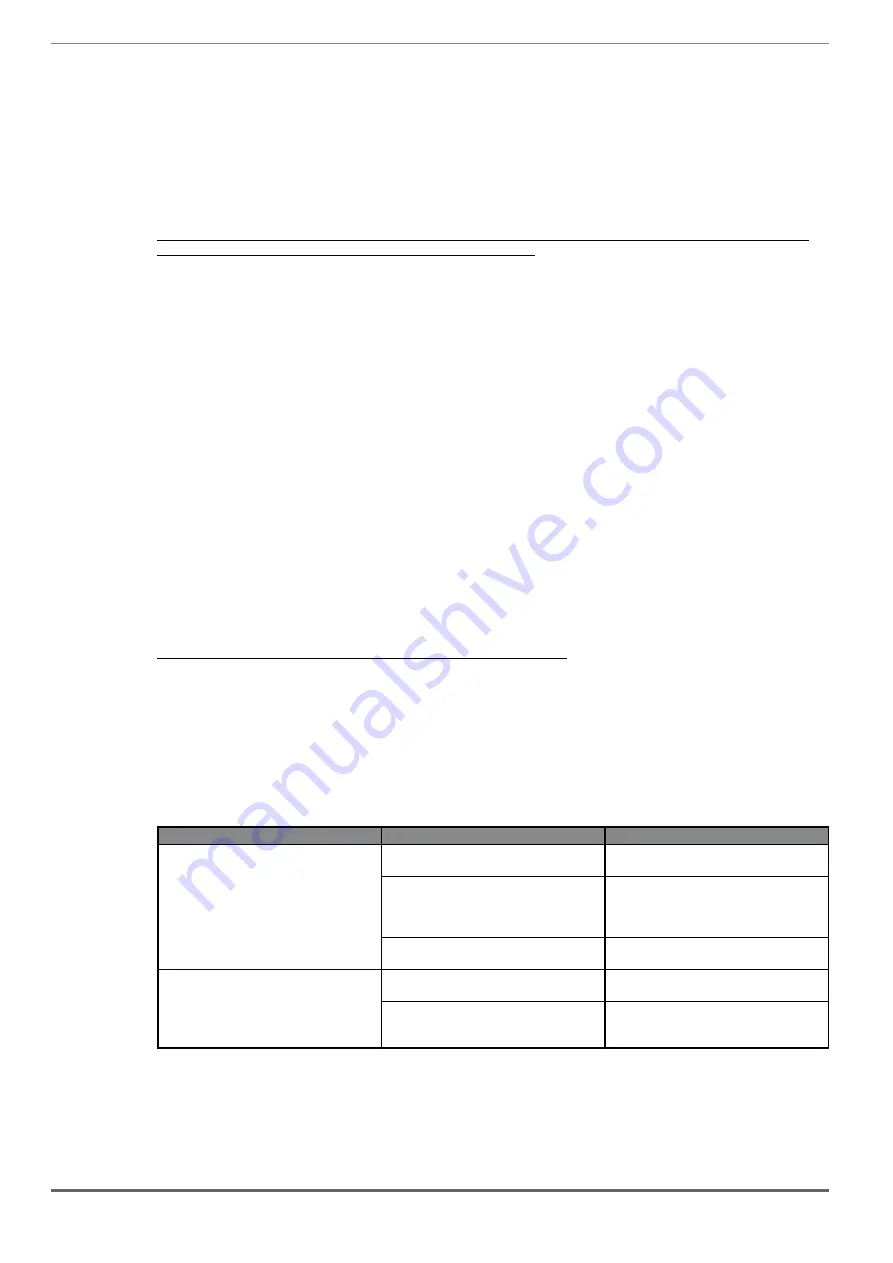

A.4.4 Troubleshooting

Fault

Possible cause

Solution

Motor does not run, the brake fault alarm is

triggered continuously

Feedback signals disconnected/incorrectly

connected

Re-check brake feedback signal wiring and

electric levels

Brake feedback not configured correctly

Check PAR 11236

Brake fbk src,

PAR 11252

Brake fbk A3 sel

configuration. Check correct

signal operation (electric levels) and invert

digital inputs if necessary

Monitoring time too short in relation to system

response times

Set a longer

PAR 11206

Brake Hold Off time

The motor runs even with the feedback

signals disconnected

The brake fault alarm is not connected.

Check the setting of PAR 11252

Brake Fbk

Sel A3

.

Incorrect PAR 11252

Brake fbk A3 sel

/ PAR

11236

Brake fbk src

setting.

PAR 11252

Brake fbk A3 sel

and PAR 11236

Brake fbk src

must not be set to

Null

or

Brake Cont Mon

.

Содержание ADL500

Страница 95: ......