51

DIAGNOSTIC CODES FOR STATUS LED

A RED LED is provided to indicate furnace operating status

LED Condition

Fault Condition

Check

LED ON

Normal operation

No action required. Control OK.

LED OFF

No power to control or

control

hardware fault detected

Line voltage input power at L1 and Neutral

connectors control board.

System wire harness in good condition and

securely connected at both ends.

1 Flash

High limit switch open

Open limit switch.

Limit switch and wiring in good condition and

securely connected.

Check for blocked air filter, correct temperature rise,

blower speed selection, closed ducts, ect.

2 Flashes

Pressure switches open

with inducer on

Pressure switches operation, tubing and wiring.

Obstruction or restrictions in venting preventing

proper air flow.

3 Flashes

Pressure switches closed

with inducer off

Pressure switches stuck closed.

Pressure switches mis-wired or jumpered.

4 Flashes

Control in 1 hour lockout

Gas supply OFF, or gas supply pressure too low to

operate furnace.

Damaged or broken HSI element.

Line voltage input power at L1 and Neutral

connectors control board.

Furnace not properly earth grounded.

Flame sensor rod contaminated or in incorrect

position.

HSI element located in wrong position.

Hot surface element or flame sensor wiring in good

condition and properly connected.

5 Flashes

L1/Neutral Polarity problem Check supply voltage to ensure proper polarity to

L1 and Neutral connections.

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

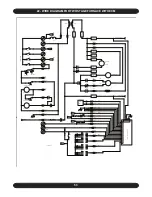

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...