47

Additional dehumidification can be achieved by

connecting a humidistat to the DEHUM and R ter-

minals on the integrated furnace control board. In

this setup, the variable speed motor will operate at

a 10% reduction in the normal cooling airflow rate

when there is a call for dehumidification.

Both dehumidification methods described above

can be utilized on the same furnace.

SETTING BLOWER “ON”

AND “OFF” TIMINGS

Blower on/off delays are handled by ECM

motor programming. The control de-energizes the

ECM heat signal when the gas valve de-energizes.

Features of this ECM variable speed motor are that

it will deliver a constant airflow within a wide range

of external static pressures, and also includes:

Soft Start:

This ECM variable speed motor will

slowly ramp up to the required operating speed.

This feature in the heating cycle allows the heat

exchanger to reach operating temperature before

the set heat speed, which minimizes noise and in-

creases comfort.

Soft Stop:

At the end of the heating or cooling

cycle, the ECM variable speed motor will slow-

ly ramp down. This feature allows for increased

energy efficiency, and reduced noise levels.

!

!

!

!

21 - MAINTENANCE AND TROUBLESHOOTING

CONTINUOUS FAN OPERATION

When the thermostat continuous fan (G) switch is

on without a call for heat or cooling, the indoor fan

is immediately energized up to 50% of the cooling

speed. The fan remains energized as long as the

call for fan remains without a call for heat or cool-

ing. This feature allows continuous circulation of air

between calls for heating or cooling.

If a call for heat (W) occurs during continuous fan,

the blower will remain energized.

If a call for cool (Y) occurs simultaneously with the

call for fan (G), the call for cool overrides the call

for fan and the blower remains off for the cooling

on delay period.

WARNING

DISCONNECT THE ELECTRICAL POWER SUP-

PLY TO THE FURNACE BEFORE ATTEMPTING

ANY MAINTENANCE. FAILURE TO DO SO CAN

CAUSE ELECTRICAL SHOCK RESULTING IN

PERSONAL INJURY OR LOSS OF LIFE.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Always verify proper operation after servicing.

TABLE 4 - CONTINUOUS FAN CFM

MODEL

Motor

HP

COOL

Jumper

ADJUST

Jumper

Continuous

Fan (CFM)

95V060-3

1/2

A

NORM

600

95V080-3

1/2

A

NORM

600

95V080-4

3/4

A

NORM

825

95V100-5

1

A

NORM

865

95V120-5

1

A

NORM

930

Note:

Moving the ADJUST jumper from the NORM position to the (+)

or (-) position will increase or lower the continuous fan CFM by 15%

AIR FILTER

The filter should be inspected frequently and

cleaned as necessary. We recommend a monthly

inspection at first, perhaps coinciding with the ar-

rival of the monthly fuel bill as a reminder. The fre-

quency may be increased or decreased depending

on experience and conditions.

Avoid the use of the fiberglass throw-away filters.

They tend to block up quickly, which may result in

higher than normal operating temperatures, and

lower efficiency.

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

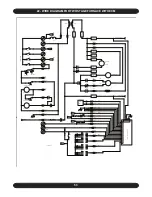

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...