49

!

!

7. Keep combustible articles at least 3 feet away

from the furnace. Do not block access for ser-

vicing the furnace Do not use the combustion

air or exhaust piping as a hanger for clothes or

anything else.

IMPORTANT:

Never attempt to operate the fur-

nace without the blower door and combustion

compartment door in place or when the blower

has failed.

ANNUAL INSPECTION/SERVICE

The furnace must be inspected annually by a quali-

fied installation contractor, service agency or fuel

supplier. Your annual inspection will normally cover

the following:

HEAT EXCHANGER -

The heat exchanger should

be inspected for corrosion. The flue passages (heat

exchanger tubes) should be free of scale or exces-

sive corrosion. The top row of heat exchanger tubing

is accessible for cleaning with a small diameter wire-

handled brush by removing the burner assembly. The

bottom row is only accessable if the heat exchanger

is removed and the rear flue box cover is removed.

The recovery coil (secondary heat exchanger) may

be cleaned by accessing the rear flue box cover or

removing the front manifold cover. After clearing ac-

cumulated scale, observe the burner flames. If there

appears to be flame distortion, check the combustion

air intake and exhaust piping and terminals for block-

age. Also check for signs of soot in the condensate

drainage. If flame distortion continues after eliminat-

ing the blockage in the piping as the cause, it may be

necessary to replace the tubular heat exchanger.

NOTE:

Prior to removal of rear flue box cover or front mani-

fold cover, ensure that replacement gaskets are available

to ensure proper sealing of the heat exchanger when re-

assembled.

BURNERS -

The burners should be inspected

to ensure that they are free of deterioration, dust

and debris, and properly aligned with the heat ex-

changer. In most cases, a simple vacuuming with a

brush attachment will adequately clean the burner

assembly and burner compartment.

CAUTION

Be careful when working on the burner

assembly. The hot surface igniter is fragile

and can break easily.

The flame sensor should be inspected and cleaned

with fine steel wool or Scotch-Brite™ scrubbing

pad. The wiring connection should be checked to

ensure that it is tight and corrosion free.

NOTE:

This is a critical connection. Small amounts of cor-

rosion can significantly increase the internal resistance of

the connection. A relatively small increase in resistance

can result in a large decrease in flame signal.

DRAINAGE -

The condensate drainage system

should be inspected and cleaned if necessary. If

the drain trap assembly, or any other component

becomes blocked, condensate may backup into

the secondary or primary heat exchanger causing

nuisance trip-outs of the pressure switches or limit

switch. The condensate should be observed for

signs of dirt, carbon, debris, etc.

If a condensate neutralizer has been added to the

condensate drain, it should be inspected, cleaned,

or the condensate neutralizing media should be re-

placed to ensure clear condensate flow.

INDUCED BLOWER -

The induced blower mo-

tor should be inspected and cleaned if necessary.

Clear any dust buildup from the ventilation ports.

CIRCULATING FAN -

The condition of the circulat-

ing fan should be checked to ensure that it is free of

excessive dust buildup, debris, etc. The mechani-

cal fasteners should be inspected and checked for

proper tightness and parts alignment. The motor

ventilation ports should be cleaned if necessary to

prevent restriction to cooling by air over the motor.

ELECTRICAL -

All electrical connections should

be examined to ensure that they are tight and cor-

rosion free. Repair any connections that have be-

come loose or corroded.

FURNACE OPERATION -

The furnace should be

cycled during the annual inspection and servicing to:

1. Test all safety related controls.

2. Determine that the temperature rise falls

within the range shown on the appliance rating

plate.

3. Ensure that the burner ignition is smooth and

that the flames are smooth soft blue, and not

impinging on the heat exchanger.

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

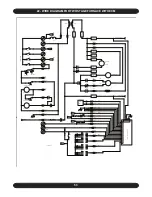

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...