44

For proper furnace operation, air flow over the heat

exchanger is of utmost importance. Insufficient

airflow accelerates metal fatigue and failure in the

heat exchanger and excessive airflow promotes

accelerated corrosion of the heat exchanger.

IMPORTANT:

Do not bypass this step of the

start up procedures.

TEMPERATURE RISE CHECK

When the duct system is complete and the air filter or

filters are in place, determine if the airflow is correct

for both low and high fire input rates..

1. Insert a duct thermometer in the supply air

duct. The thermometer should be placed as

close as practical to the furnace, but out of the

“line of sight” of the heat exchanger (this pre-

vents false readings owing to radiant heat). En-

sure that the thermometer location is within the

duct air stream. Avoid locations such as the in-

side radius of an elbow, etc.

20 - AIR FLOW

Any adjustments to the burner manifold pressure

should be carried out with the use of a manometer

or calibrated magnehelic gauge. Do not adjust the

gas valve pressure regulator more than ±0.3” w.c.

IMPORTANT:

Never adjust the input of the furnace

to exceed the input shown on the rating plate.

In the previous example where the heating value of

the gas is 1100 BTU/cu. ft., the burner manifold pres-

sure can be reduced 3% to 3.4” w.c., which is within

the ±0.3” w.c. specification to bring the input into

compliance. Refer also to

“Setting the Gas Manifold

Pressure”

and

“High Altitude in the Gas Supply &

Piping”

section of this manual. Contact the fuel sup-

plier for specific gas heating content values.

Input =

Heating Value of Gas x 3600

Time in Sec. for 1 cu. ft.

where:

input is expressed in BTU/Hr

heating value of the gas is expressed in BTU/ft

3

and time is the number of seconds required for

the test dial to indicate 1 cubic foot.

•

•

•

If using a gas meter with SI (metric) units:

1 cubic foot = 0.0283 cubic meters

1 cubic meter = 35.315 cubic feet

0.01 cubic meter = 0.3531 cubic feet

0.5 cubic meter = 1.766 cubic feet

•

•

•

•

TABLE 1B - AIR FLOW FOR TEMPERATURE RISE

Furnace

Model

High Fire (HF) CFM Required for a ▲T of:

35

45

55

65

60

1501

1167

955

808

80

2001

1557

1274

1078

100

2502

1946

1592

1347

120

3002

2335

1910

1616

Furnace

Model

Low Fire (LF) CFM Required for a ▲T of:

25

35

45

55

60

901

700

573

485

80

1201

934

764

647

100

1501

1167

955

808

120

1801

1401

1146

970

TABLE 1A - RANGE OF TEMPERATURE RISE

Furnace Model

Temperature Rise

60, 80, 100, 120

High Fire (HF) 35 - 65°F

Low Fire (LF) 25 - 55°F

TABLE 10 - AIR FLOW

MODEL 95V

ESP 0.1” to 1.0” w.c.

Input

A/C

Tonnage

ADJUST

Jumper

COOL

Jumper

CFM

60000

3 Ton

NORM

A

1200

B

1000

C

800

D

600

80000

3 Ton

NORM

A

1200

B

1000

C

800

D

600

80000

4 Ton

NORM

A

1600

B

1200

C

1000

D

800

100000

5 Ton

NORM

A

2000

B

1600

C

1200

D

800

120000

5 Ton

NORM

A

2000

B

1600

C

1200

D

800

Note: Moving the ADJUST jumper from the NORM position to the

(+) or (-) position will increase or lower the CFM by 15%

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

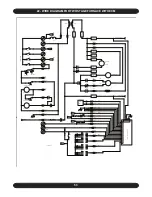

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...