Page 1

1998 Lennox Industries Inc.

Litho U.S.A.

Corp. 9804-L4

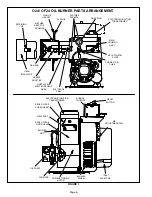

O24/OF24

Service Literature

O24 / OF24 SERIES UNITS

O24 (Elite 80

) series units are heating only mid-efficiency

upflow oil furnaces manufactured with Beckett oil burners.

O24 units are available in heating capacities of 70,000 to

154,000 Btuh (20.5 to 45.1 kW). O24 units are suitable for resi

dential or commercial applications.

OF24 (Elite 80) series units are heating only mid-efficiency lo-

boy up-flow furnaces, which cime in front (OF24) or rear

(OF24R) flue openings. Both furnaces use Beckett oil burners

with heating capacities of 105,000 to 154,000 Btuh (30.8 kW to

45.1 kW). OF24 units are suitable for residential or commercial

application.

The drum type heat exchanger comes with strategically

placed ports allowing easy cleaning. The oil burner can be

easily removed for inspection and service. The mainte

nance section gives a detailed description on how this is

done.

Information contained in this manual is intended for use by

experienced HVAC service technicians only. All specifica

tions are subject to change. Procedures outlined in this

manual are presented as a recommendation only and do not

supersede or replace local or state codes.

O24 UPFLOW

OF24

REAR FLUE

MODEL

OF24

FRONT FLUE

MODEL