42

!

!

ELECTRONIC AIR CLEANER

The integrated furnace control has provisions to

supply power and control an electronic air clean-

er rated at 120vac, 1.0 amp max. 120 volt power

will be available at these terminals whenever the

circulating fan is operating in the heating or cooling

modes.

18 - OPTIONAL ACCESSORIES (FIELD SUPPLIED/INSTALLED)

POWER HUMIDIFIER

The integrated furnace control has provisions to

supply power and control a line voltage humidi-

fier or the primary of a 120 / 24 volt humidifier step

down transformer, rated at 120vac, 1.0 amp max.

NOTE:

All HUM and EAC terminals are 120V. Do not di-

rectly connect 24V equipment to these terminals.

19 - STARTUP PROCEDURES

This furnace is equipped with a HSI (Hot Surface

Ignition) device. Each time that the room thermostat

calls for heat, the HSI lights the main burners di-

rectly. See the lighting instructions on the furnace.

TO START THE FURNACE

1. Remove the burner compartment access door.

2. Shut off the electrical power to the furnace and

set the room thermostat to its lowest setting.

IMPORTANT:

Ensure that the manual gas con-

trol switch has been in the “OFF” position for at

least 5 minutes. Do not attempt to manually light

the main burners.

3. Turn the gas control switch to the “ON” position.

4. Replace the burner compartment access door.

5. Restore electrical power to the furnace.

6. Set the room thermostat to a point above room

temperature to light the furnace.

7. After the burners are lit, set the room thermostat

to the desired temperature.

TO SHUT DOWN THE FURNACE

1. Set the room thermostat to its lowest setting.

2. Remove the burner compartment access door.

3. Turn the gas control switch to the “OFF” position.

4. The furnace appliance shut-off valve may be

closed if desired.

5. Power to the furnace must remain on for the air

conditioner to work.

WARNING

SHOULD OVERHEATING OCCUR OR THE

GAS BURNERS FAIL TO SHUT OFF, CLOSE

THE MANUAL GAS VALVE FOR THE FUR-

NACE BEFORE SHUTTING OFF THE ELEC-

TRICAL POWER TO THE FURNACE. FAILURE

TO DO SO CAN CAUSE AN EXPLOSION OR

FIRE RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

BEFORE RESTARTING THE FURNACE,

CHECK ALL PLASTIC VENTS AND WIRES

FOR DAMAGE.

uous low heat operation. Once high heat is started

from automatic staging, the demand for high heat

remains until the heat call is satisfied.

* Factory Setting

TWO STAGE THERMOSTAT

When connecting a two stage thermostat, the jump-

er (P5) must be in the “NONE” position. The control

runs high heat from the thermostat W2 demand.

THERMOSTAT LOCATION

The thermostat should be located approximately 5

feet above the floor, on an inside wall where there is

good natural air circulation, and where the thermostat

will be exposed to average room temperatures. Avoid

locations where the thermostat will be exposed to cold

drafts, heat from nearby lamps or appliances, expo-

sure to sunlight, heat from inside wall stacks, etc.

THERMOSTAT HEAT ANTICIPATOR SETTING:

0.1 AMP (Honeywell)

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

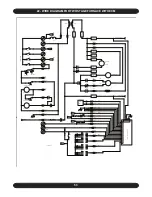

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...