46

95V060-3

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

700

1050

B

NORM

850

1105

C

NORM

575

880

D

NORM

525

819

95V080-3

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1050

1376

B

NORM

1250

1400*

C

NORM

900

1242

D

NORM

780

1108

* Motor CFM maxium

95V080-4

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1000

1350

B

NORM

1150

1495

C

NORM

900

1206

D

NORM

800

1104

95V100-5

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1200

1620

B

NORM

1400

1820

C

NORM

1100

1474

D

NORM

950

1349

Note:

Moving the ADJUST jumper from the NORM position to the

(+) or (-) position will increase or lower the temperature rise

by 15%

95V120-5

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1650

2200*

B

NORM

1900

2200*

C

NORM

1500

2070

D

NORM

1325

1815

* Motor CFM maxium

If the blower speeds require adjustment, follow

these steps:

1. Remove the blower compartment door.

2. Locate the 4 position movable HEAT jumper

to adjust heat speed.

3. Remove the jumper from position A

and place it on the corresponding letter B, C,

or D as required. Refer to TABLE 2 - HEATING

SPEEDS.

NOTE:

Temperature rise should always be re-checked

whenever blower speed is changed.

4. To adjust the cooling airflow, remove

the COOL jumper from position A and place

it on the corrosponding letter B, C, or D. Refer

to TABLE 10 AIR FLOW.

Moving the ADJUST jumper from the NORM to

the (+) or (-) position will cause the airflow to be

increased or lowered by 15%.

The TEST position on the ADJUST tap is not

used.

DEHUMIDIFICATION:

For situations where humidity control is a problem,

a dehumidification feature has been built into the

variable speed motor. At the start of each cooling

cycle, the variable speed motor will run at 82% of

the rated airflow for 7.5 minutes. After 7.5 minutes

has elapsed, the motor will increase to 100% of the

rated airflow. If this feature is not desired, clip the

jumper wire between Y and O on the integrated fur-

nace control board. With Y and O not jumpered, the

variable speed will reach 100% of the rated airflow

within 10 seconds of a call for cooling.

TABLE 3 - HEATING CFM

Содержание G95V

Страница 27: ...27 FIGURE 21A DIRECT VENT TERMINAL CLEARANCES...

Страница 28: ...28 FIGURE 21B NON DIRECT VENT TERMINAL CLEARANCES...

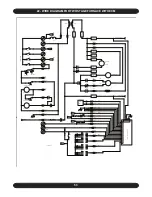

Страница 53: ...53 22 WIRE DIAGRAM FOR TWO STAGE FURNACE WITH ECM...