ENGINE C O O L IN G SYSTEM 6K-11

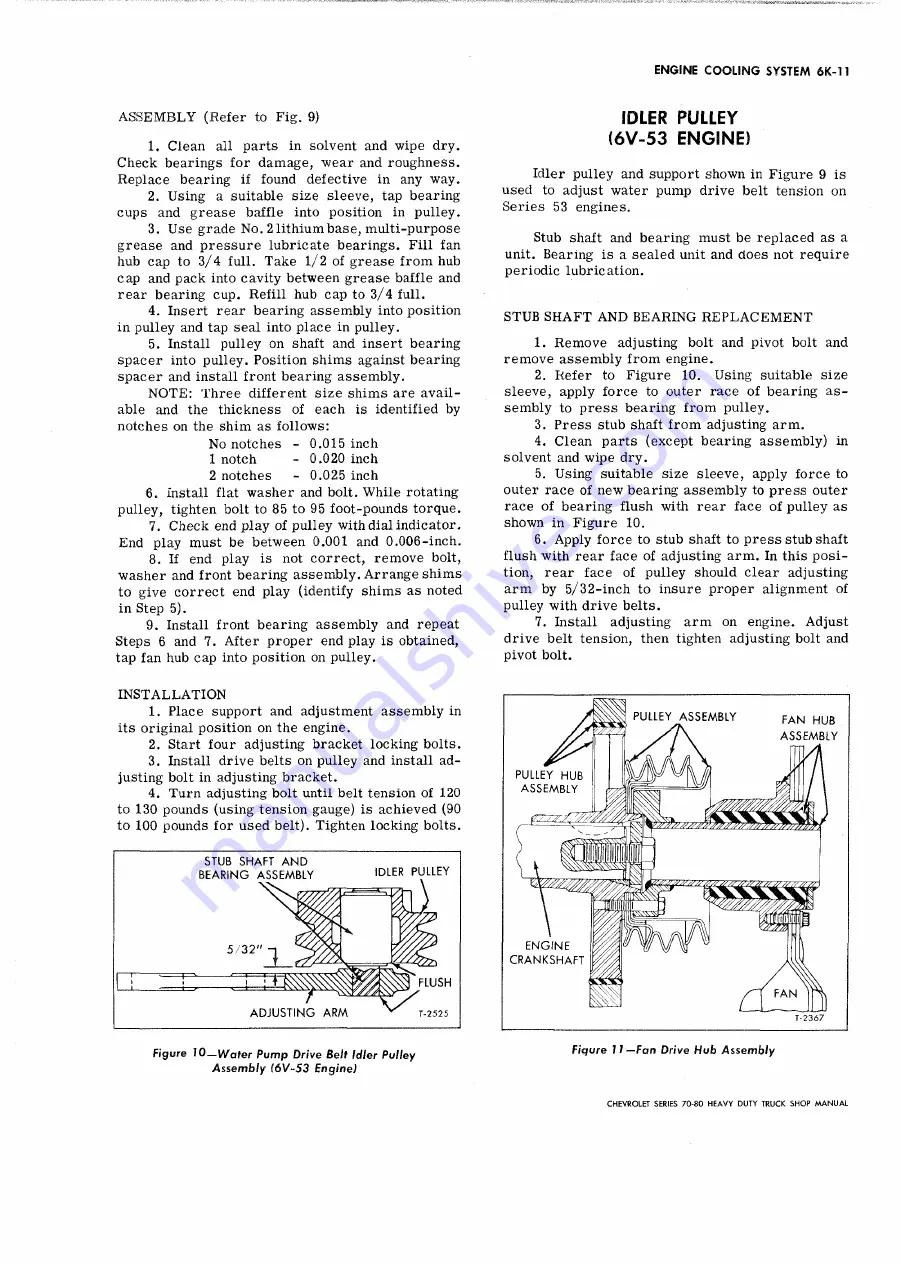

A S S E M B L Y (Refer to Fig. 9)

1. Clean all parts in solvent and wipe dry.

Check bearings for damage, wear and roughness.

Replace bearing if found defective in any way.

2. Using a suitable size sleeve, tap bearing

cups and grease baffle into position in pulley.

3. Use grade No. 2 lithium base, multi-purpose

grease and pressure lubricate bearings. Fill fan

hub cap to 3/4 full. Take 1/2 of grease from hub

cap and pack into cavity between grease baffle and

rear bearing cup. Refill hub cap to 3/4 full.

4. Insert rear bearing assembly into position

in pulley and tap seal into place in pulley.

5. Install pulley on shaft and insert bearing

spacer into pulley. Position shims against bearing

spacer and install front bearing assembly.

N O T E : Three different size shims are avail

able and the thickness of each is identified by

notches on the shim as follows:

No notches - 0.015 inch

1 notch

- 0.020 inch

2 notches

- 0.025 inch

6. Install flat washer and bolt. While rotating

pulley, tighten bolt to 85 to 95 foot-pounds torque.

7. Check end play of pulley with dial indicator.

End play must be between 0.001 and 0.006-inch.

8. If end play is not correct, remove bolt,

washer and front bearing assembly. Arrange shims

to give correct end play (identify shims as noted

in Step 5).

9. Install front bearing assembly and repeat

Steps 6 and 7. After proper end play is obtained,

tap fan hub cap into position on pulley.

IN S T A L L A T IO N

1. Place support and adjustment assembly in

its original position on the engine.

2. Start four adjusting bracket locking bolts.

3. Install drive belts on pulley and install ad

justing bolt in adjusting bracket.

4. Turn adjusting bolt until belt tension of 120

to 130 pounds (using tension gauge) is achieved (90

to 100 pounds for used belt). Tighten locking bolts.

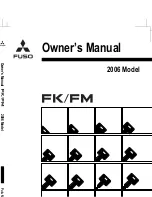

Figure 10

—Water Pump Drive Belt Idler Pulley

Assembly 16V-53 Engine)

IDLER PULLEY

(6V-53 ENGINE)

Idler pulley and support shown in Figure 9 is

used to adjust water pump drive belt tension on

Series 53 engines.

Stub shaft and bearing must be replaced as a

unit. Bearing is a sealed unit and does not require

periodic lubrication.

STUB S H A F T A N D BEARIN G R E P L A C E M E N T

1. Remove adjusting bolt and pivot bolt and

remove assembly from engine.

2. Refer to Figure 10. Using suitable size

sleeve, apply force to outer race of bearing as

sembly to press bearing from pulley.

3. Press stub shaft from adjusting arm.

4. Clean parts (except bearing assembly) in

solvent and wipe dry.

5. Using suitable size sleeve, apply force to

outer race of new bearing assembly to press outer

race of bearing flush with rear face of pulley as

shown in Figure 10.

6. Apply force to stub shaft to press stub shaft

flush with rear face of adjusting arm. In this posi

tion, rear face of pulley should clear adjusting

arm by 5 / 32-inch to insure proper alignment of

pulley with drive belts.

7. Install adjusting arm on engine. Adjust

drive belt tension, then tighten adjusting bolt and

pivot bolt.

CHEVROLET SERIES 70-80 H EAVY DUTY TRUCK SH O P M A N U A L

Содержание 70 1969 Series

Страница 1: ...CHEVROLET HEAVY DUTY TRUCK SHOP MANUAL...

Страница 3: ......

Страница 11: ...LUBRICATION 0 4 CHEVROLET SERIES 70 80 HEAVY DUTY TRUCK SHOP MANUAL...

Страница 27: ......

Страница 119: ......

Страница 361: ......

Страница 371: ......

Страница 403: ...TROUBLE ANALYSIS CHART ENGINE ELECTRICAL 6Y 32 CHEVROLET SERIES 70 80 HEAVY DUTY TRUCK SHOP MANUAL...

Страница 427: ......

Страница 443: ......

Страница 451: ......

Страница 493: ......

Страница 499: ......

Страница 549: ......

Страница 555: ......

Страница 609: ......

Страница 715: ...am...

Страница 745: ......

Страница 807: ...TRANSMISSION AND CLUTCH 7 61 CHEVROLET SERIES 70 80 HEAVY DUTY TRUCK SHOP M AN U AL Kgure 2 Clark 401 Transmission...

Страница 910: ......

Страница 913: ......