same message, if the Liquid Cooled Solid State Starter does not receive a response from the Control

Center after 10 consecutive attempts to communicate with the Control Center after Initialization

has been successfully completed. The Control Center attempts to establish communications until

successful.

LCSSS Shutdown – Requesting Fault Data...

The Liquid Cooled State Starter Logic/Trigger Board has shut down the chiller but the Control

Center has not yet received the cause of the fault from the LCSSS, via the serial communications

link. The LCSSS shuts down the chiller by opening the Motor Controller LCSSS Stop Contacts (K1

relay located on the starter Logic/Trigger Board and connected between TB6-16 and TB6-53 in the

Control Center). The Microboard, in the Control Center then sends a request for the cause of the

fault to the Logic/Trigger Board over the serial communications link. Since serial communications

are initiated every 2 seconds, this message is typically displayed for a few seconds and then

replaced with one of the following fault messages.

LCSSS – Stop Contacts Open

Refer to

LCSSS Shutdown – Requesting Fault Data

. If the Control Center’s Microboard does not receive

the cause of a starter initiated shutdown with 20 seconds of the shutdown, it is assumed it is not

forthcoming and that message is replaced with this message. The chiller can be started when the

Motor Controller LCSSS Stop Contacts close.

A missing interlock jumper between Starter Logic/ Trigger Board J1-1 and J1-12 will also produce

this message.

LCSSS – Power Fault

The Liquid Cooled Solid State Starter Logic/Trigger Board has detected that the compressor motor

current in one or more phases has decreased to less than 10% of the FLA for a minimum of 1 line

cycle. This check is inhibited during the first 4 seconds of System Run and until the motor current

is greater than 25% of the Job FLA. The chiller will automatically restart upon completion of System

Coastdown.

LCSSS – Low Phase (X) Temperature Sensor

The Liquid Cooled Solid State Starter Logic/Trigger Board has detected that the temperature of the

starter phase A, B or C (designated as X in the message) Silicon Controlled Rectifier (SCR) Module

has decreased to less than 37°F. This would generally be indicative of a disconnected or defective

sensor. If all three SCR Modules are indicating a temperature of less than 37°F, the SCR Module

cooling pump turns on. This is accomplished by disconnecting all three sensors. This feature allows

Service Technicians to run the cooling pump while filling the cooling system by disconnecting plugs

P2, P3 and P4 in the LCSSS.

LCSSS – Run Signal

The Liquid Cooled Solid State Starter receives two start signals from the Control Center

simultaneously; one via the serial communications link and one via the start relay TB6-24 in the

Control Center. If they are not received within 5 seconds of one another, a cycling shutdown is

performed and this message is displayed. This is generally indicative of defective wiring.

LCSSS – Invalid Current Scale Selection

There is an invalid compressor motor current scale jumper combination installed in the Liquid

Cooled Solid Starter Logic/Trigger Board J1. Jumper combination determines allowable “100% FLA”

setpoint range; 7L-35 to 260A, 14L-65 to 510A, 26L-125 to 850A and 33L-215 to 1050A. The chiller will

be permitted to start when the jumpers are configured correctly. Refer to

Solid State Starter (Mod

“B”) – Operation and Maintenance (Form 160.00-O2)

for valid jumper configurations.

YK-EP Style B Centrifugal Chiller

200

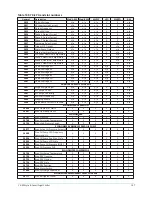

Summary of Contents for YK-EP

Page 2: ...2 YK EP Style B Centrifugal Chiller...

Page 6: ...6 YK EP Style B Centrifugal Chiller...

Page 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Page 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Page 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Page 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Page 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Page 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Page 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Page 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Page 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Page 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...