Warning – Motor – High Bearing Vibration

Either the Shaft End or Opposite Shaft End motor bearing vibration has exceeded the value

programmed for the High Vibration Warning Setpoint for the programmed number of Delay

seconds. The warning will automatically clear when both vibration values decrease below the

warning threshold. This warning does not occur when the Motor Vibration Protection Setpoint is set

to Disabled on the MOTOR DETAILS Screen or while the WARNING – MOTOR – BEARING VIBRATION

BASELINE NOT SET warning is displayed.

Routine shutdown messages

Remote Stop

A shutdown command has been received from a remote device. Remote stop commands can be

received in Digital Remote mode via I/O Board TB4-7/8 or in ISN (BAS) Remote mode via the SC-

EQ communication card serial communications. If the chiller is running when this occurs, the Pre-

Rotation Vanes are driven fully closed prior to shutting down the chiller.

Local Stop

A local shutdown command has been received by pressing the Soft Stop Key on the Home screen.

Place Compressor Switch In Run Position

The Control Center is in either Digital or ISN (BAS) Remote mode. The Operator is requested to

press the Start Key on the Home Screen. As a safety measure the Control Center will not accept a

Remote start/stop command unless the Start key is initially pressed.

Cycling shutdown messages

Multiunit Cycling – Contacts Open

The Multiunit Cycling contacts connected to I/O Board TB4-9, have opened to initiate a cycling

shutdown. If the chiller is running when this occurs, the Pre-Rotation Vanes are driven fully closed

prior to shutting down the chiller. The chiller will automatically restart when the contacts close.

System Cycling – Contacts Open

The System Cycling contacts connected to I/O Board TB4-13, have opened to initiate a cycling

shutdown. If the chiller is running when this occurs, the Pre-Rotation Vanes are driven fully closed

prior to shutting down the chiller. The chiller will automatically restart when the contacts close.

Oil – Low Temperature Differential

The chiller is prevented from starting because for one of the following reasons. The chiller will

automatically restart when the conditions have been satisfied. This condition is only checked while

the chiller is stopped. In previous software versions, it is checked when stopped and during the first

10 seconds of prelube.

The chiller has been shut down for less than or equal to 30 minutes and the oil temperature minus

the condenser saturation temperature is less than 30°F.

-OR-

The chiller has been shut down for greater than 30 minutes and the oil temperature minus the

condenser saturation temperature is less than 40°F.

-OR-

Following a power failure, upon restoration of power, the oil temperature minus the condenser

saturation temperature is less than 40°F.

YK-EP Style B Centrifugal Chiller

196

Summary of Contents for YK-EP

Page 2: ...2 YK EP Style B Centrifugal Chiller...

Page 6: ...6 YK EP Style B Centrifugal Chiller...

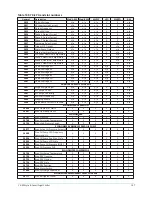

Page 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Page 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Page 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Page 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Page 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Page 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Page 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Page 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Page 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Page 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...