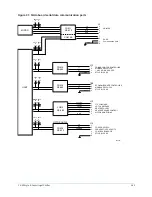

Analog inputs

System pressures, in the form of analog DC voltages, are input from Pressure Transducers. Refer

to

Form 160.54-M1

for more details. Formulas and graphs are included to calculate the expected

transducer output voltage for a given pressure input.

System temperatures, in the form of analog DC voltages, are input from thermistors. Refer to

Form

160.54-M1

for more details. Included are tables to convert the expected output voltage for any

temperature applied to the thermistor.

Flow switch

The chillers are supplied with factory-mounted Flow Sensors on the evaporator and condenser.

These are electronic thermal-type sensors. The operating principle of the sensor is thermal

conductivity. It uses the cooling effect of a flowing liquid to sense flow. The temperature of the

heated sensor tip is sensed by a thermistor located in the tip. A second thermistor, located higher

in the tip in a non-heated area, is only affected by changes in liquid temperature. The temperatures

sensed by the thermistors are compared. Flowing liquid carries heat away from the heated sensor

tip, lowering its temperature. The higher the flow rate, the lower the tip temperature and therefore

a lower differential between thermistors. Lower flow rates remove less heat from the tip allowing

a higher tip temperature. The lower the flow, the greater the differential between thermistors. The

sensor is vendor-calibrated to turn ON its output at a flow rate of 20cm (0.6 ft.)/second.

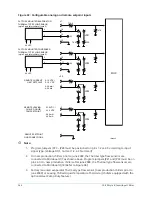

The sensor operates from a 24VAC power source and has a solid state relay output. On each sensor,

one side of the solid state relay (pin 4) is connected to +5VDC on the microboard and the other

side (pin 2) is connected to an Analog Input of the microboard (Refer to

Form 160.54-M1

for more

details). After power is applied, there is a thermal warm-up period of up to 20 seconds. During this

time, the output could be unstable. When the setpoint (or greater) flow rate is sensed, the solid

state relay output is turned ON causing it to conduct current through the 7.5K ohm Microboard

load resistor to the +5VDC. This applies greater than +4VDC to the microboard input. When a flow

rate less than the setpoint is sensed, the solid state relay output is turned OFF, resulting in no

conduction through the load resistor. This applies less than 1VDC to the microboard input. To

determine the state of the solid state relay, first confirm that +5VDC is present at pin 2 of the flow

sensor. Then connect a voltmeter between the microboard TP1 (GND) and the respective flow

sensor input to the microboard.

The software accommodates either the Paddle type sensors connected to TB4 of the I/O Board or

the Thermal type sensors connected to J14 on the microboard. To assure the program reads the

correct input, the Flow Switch setpoint on the OPERATIONS Screen must be set appropriately .

Serial data ports

Microboard 031-03630-007 is equipped with 6 serial ports. Each port is dedicated for a specific

function as follows:

1. COM1 (J2) – RS-232. Printer.

2. COM2 (J13) – RS-485. Modbus communications to the Primary Liquid Cooled Solid State

Starter, Medium Voltage Solid State Starter, Medium Voltage Variable Speed Drive or Variable

Speed Drive.

3. COM3 (J12) – RS-485. LTC I/O and Motor Monitoring.

4. COM4 (J2) – RS-232. SC-EQ communication card.

5. COM5B (TB4) – RS-485. Future VGD actuator.

6. COM6 J29 & J30 Fiber Optic cable to LCSSS.

Each port is equipped with two LED’s. A red TX LED illuminates as data is transmitted to or

requested from another device. A green RX LED illuminates as data is received from another device.

YK-EP Style B Centrifugal Chiller

250

Summary of Contents for YK-EP

Page 2: ...2 YK EP Style B Centrifugal Chiller...

Page 6: ...6 YK EP Style B Centrifugal Chiller...

Page 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Page 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Page 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Page 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Page 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Page 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Page 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Page 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Page 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Page 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...