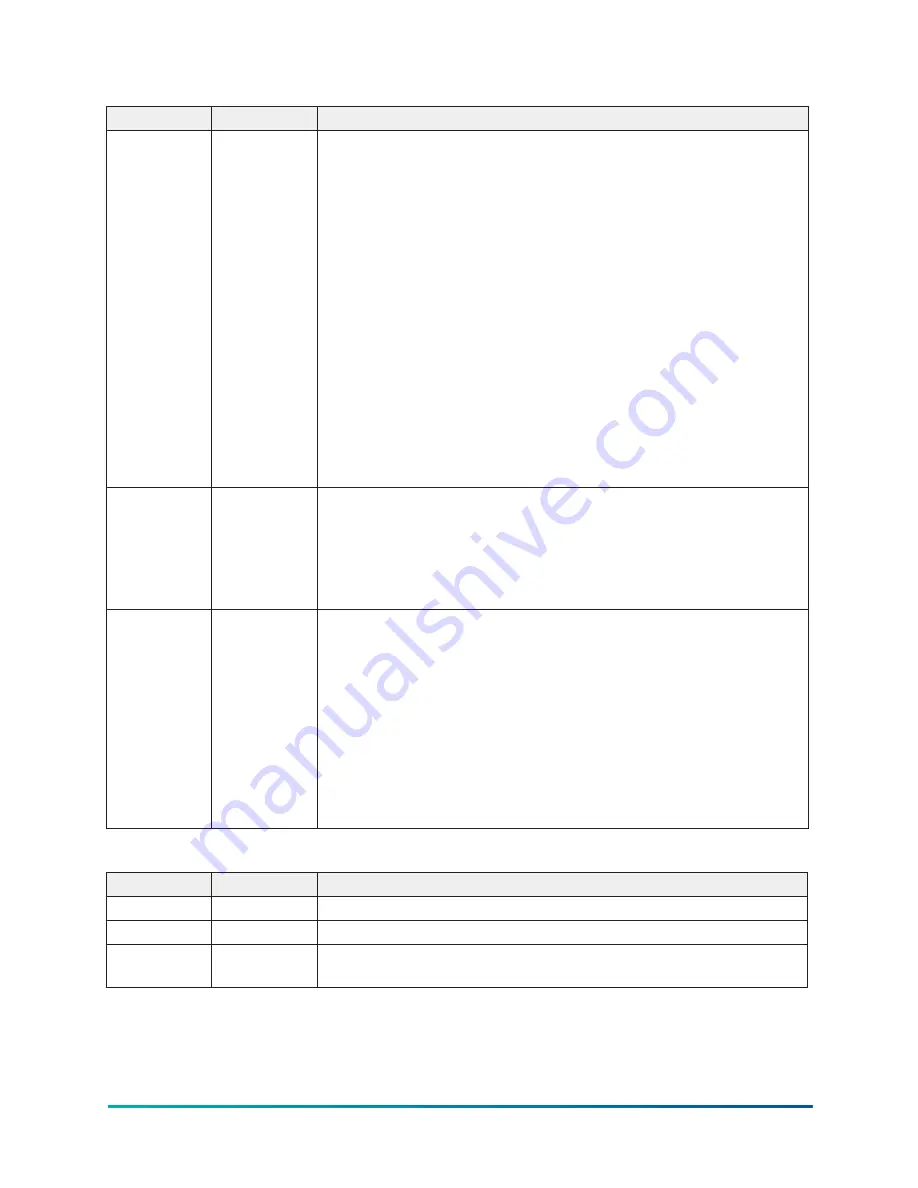

Table 131: Programmable

Button

Access level Description

Motor

Cooling

Coil Leak

Protection

Service

Enables the type of leak protection device being used to detect a

leak of the motor cooling coil. When set to any setting other than

Disabled, an LED status indicator is displayed and the Motor Cooling

Coil safety fault will occur when the sensor indicates a leak. The

settings are:

•

DISABLED - Disables the Motor Cooling Coil Leak Protection

feature. The status LED and text do not appear. The Motor

Cooling Coil Leak fault will not occur. This setting is used

when the motor is not equipped with a leak detector or if it is

desired to disable this feature for service reasons. This is the

default setting.

•

OPTICAL - Enables the optical sensor digital input and displays

the leak status, as reported by the optical leak sensor, via the

Motor Monitoring Board serial communications.

•

FLOAT - Enables the float sensor digital input and displays the

leak status, as reported by the float leak sensor, via the Motor

Monitoring Board serial communications.

Manual

Baseline

(Motor

Bearing

Vibration)

Service

Used to manually enter a vibration baseline value (0.1 to 5; default

2) for the Shaft End and Opposite Shaft End bearings. The vibration

values are not in any particular units of measure. They are relative

values. The larger the number, the greater the magnitude of

vibration represented. Values entered appear on this screen as the

Vibration Baseline values. A special password is required.

Auto

Baseline

(Motor

Bearing

Vibration)

Service

Used to run the auto baseline routine. Only allowed after the

chiller has been running for greater than 2 minutes. The vibration

level of each bearing is independently averaged for 1 hour at 1

minute intervals while the chiller is running. While the routine is

running, the time remaining in the 1 hour routine is displayed as

auto baseline time left on this screen. At the completion of the

routine, the derived values appear on the screen as the Vibration

Baseline values (0.1 - 5; default 2). The vibration values are not in

any particular units of measure. They are relative values. The larger

the number, the greater the magnitude of vibration represented. A

special password is required.

Table 132: Navigation

Button

Access Level Description

Home

View

Returns user to HOME screen

Motor

View

Returns user to MOTOR screen

Setpoints

Service

Moves to a subscreen allowing programming of additional motor

monitoring setpoints

135

YK-EP Style B Centrifugal Chiller

Summary of Contents for YK-EP

Page 2: ...2 YK EP Style B Centrifugal Chiller...

Page 6: ...6 YK EP Style B Centrifugal Chiller...

Page 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Page 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Page 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Page 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Page 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Page 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Page 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Page 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Page 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Page 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...