EZZ023535

4 / 35

3.

Synchronous Control

3.1

Overview

Synchronous Control synchronizes the operation of two motors when the machine will be

operated using two independent motors.

This function can control tilting of the transported load caused by unsynchronized operation

and stress applied to the movement mechanism of the crane.

Synchronous Control has the following two modes:

Speed Synchronization Mode (SA-31 = 1)

The crane is operated by synchronizing the speed of the master and slave. The result of

multiplying the speed of the master by the gear ratio is used as the speed reference of the

slave.

Position Synchronization Mode (SA-31 = 2)

The crane is operated by synchronizing the speed and position of the master and slave.

Position Synchronization mode uses multi-function digital inputs, and the deviation in position

between the master and slave can be compensated using parameter setting values

(Advance/Retard Compensation) and detected value (Alignment).

◆ Applicable Control Modes

• Closed Loop Vector (A1-02=3)

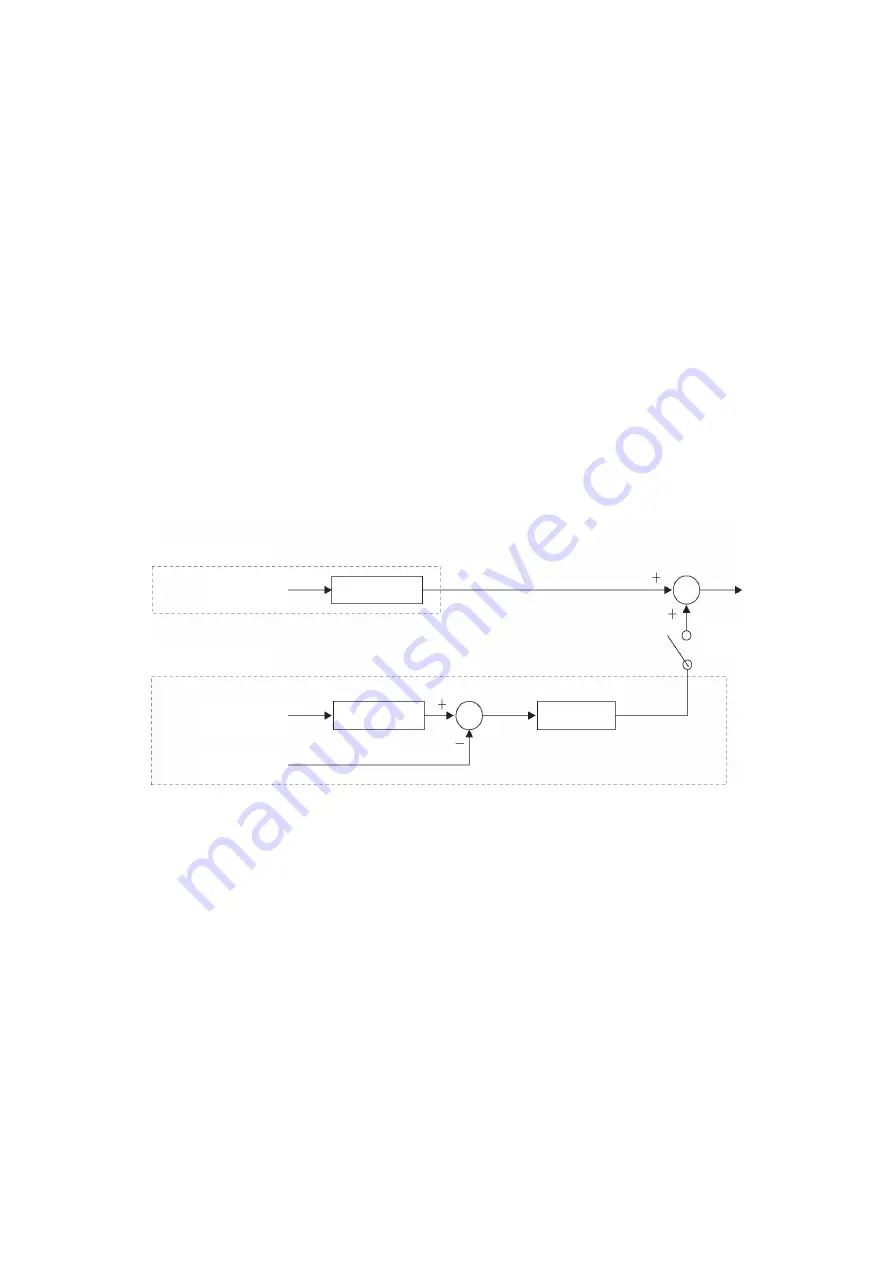

Figure 3.1 Simplified Block Diagram of Synchronous Control

3.2

Application Precautions

・

Construct a system that can monitor the READY signals and simultaneously run and stop

the motors. Additionally, simultaneously stop the motors when stopping the machine, such

as when a fault or Fast Stop occurs. If locking the motors with brakes or other equipment,

construct a system that simultaneously releases and applies the brakes. In a system where

the motors are mechanically locked, the machine may be damaged if only one motor is locked.

・

Set the gear ratio (mechanical gear ratio × digital gear ratio) to match the speed standard

for master and slave. If there is an error in the gear ratio, a deviation will occur in the positions

of the master and slave over time. The error in the mechanical gear ratio can be adjusted in

a stepless manner with the digital gear ratio. Position compensation can also be performed

with Advance/Retard Compensation and Alignment using multi-function digital inputs.

・

Set Maximum Output Frequency (E1-04) of the slave to a value that is about 10% (Position

Control Output Limit) larger than the maximum output frequency of the master.

・

In high-speed regions, the accuracy of position compensation using multi-function digital

inputs (Advance/Retard Compensation and Alignment) decreases.

Speed synchronizer

Slave

frequency

reference

Master encoder

speed

Gear calculation

Position synchronizer

Slave encoder

pulse count

Gear calculation

Master encoder

pulse count

SA-31 = 2

Position controller

Summary of Contents for CR700

Page 1: ......

Page 244: ...3 13 Test Run Checklist 244 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual ...

Page 422: ...7 7 Storage Guidelines 422 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual ...

Page 426: ...8 2 Disposal Instructions 426 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual ...

Page 837: ...EZZ023535 2 35 1 Revision History Revision Revised Content Date First Edition 2017 08 ...

Page 872: ...EZZ023536 2 16 Revision History Revision Revised Content Date First Edition 2017 08 ...