Periodic Maintenance

Procedure Interval

To ensure peak GC/MS performance, you need to perform periodic maintenance

on the vacuum and cooling systems. The following list identifies relevant

maintenance intervals.

•

Check the foreline pump oil level and oil condition weekly

•

Purge foreline pump oil weekly

•

Check cooling fans weekly

•

Change foreline pump oil and filter at least every nine months

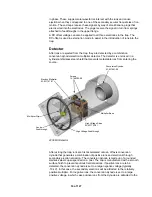

Checking Foreline Pump Oil Level and Oil Condition

Ideally, the level and condition of the pump oil should be checked with the pump

switched off and warm, though a reasonable assessment can be made with the

pump running. The oil level should be between the maximum and minimum

levels on the sight glass. If the oil level falls below the minimum level, use a

funnel to gradually add more oil (88-299517-00) through the filler port until the oil

level is centered between the maximum and minimum levels.

NOTE: Pump models are subject to change. If not using a model DS-102 pump,

refer to the pump manual for details.

The pump oil should be clear and light amber in color. If the oil becomes thick,

dark in color, becomes opaque, or has a burnt smell, change it and the Oil Mist

Filter Cartridge as described in Changing Foreline Pump Oil.

Changing Foreline Pump Oil

To ensure peak performance and maximum pump lifetime, change the pump oil

whenever the oil becomes thick, dark in color, and has a burnt smell, or at least

every six months. The oil change should be performed while the oil is warm but

not immediately after stopping the pump.

Materials Needed

•

5/16" Allen Wrench

•

Varian GP Oil (88-299517-00)

27 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...