compares the desired and actual amount of the RF voltage and adjusts the gain

of an RF amplifier to cause the actual RF voltage to equal the desired RF

voltage. Since the high voltage required at the ion trap exceeds the capabilities of

conventional electronic amplifiers, a resonant LC circuit consisting of the RF coil

and the ion trap capacitance is used. At resonance, the RF voltage at the ion trap

end of the coil is about 150 times that at the RF generator circuit end of the coil.

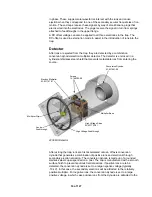

Ion Detection Board

The ion detection board contains key elements of the electronics associated with

detecting ions by either the electron multiplier or ion gauge. The board contains a

power supply that applies voltage to the cathode of the electron multiplier. That

supply consists of a chain of voltage multiplier circuits that are switched between

–800 and –3000 volts by a multiplier on signal from the controller. The ion

detection board also has the emission current regulation circuitry for the ion

gauge, as well as the electronics to obtain and condition its vacuum signal.

Ion Amplifier

The ion amplifier converts the current received from the electron multiplier to

voltage that can then be read by the controller board analog to digital converter.

This amplifier boosts the signal by a factor of 10

7

. To maximize the bandwidth,

the amplifier is mounted on the side of the vacuum manifold as close to the

multiple output feed-through as possible.

Electronic Flow Control

An electronic flow controller (EFC) controls the flow rate of helium damping gas

in external ionization mode. The EFC maintains the proper flow using a closed

loop feedback control system. The flow set point is set through a digital to analog

converter (DAC) that receives its setting from the controller board. The control

electronics then reads the flow by measuring the pressure across a known orifice

using two pressure transducers. It sets the required flow using a proportional

solenoid valve. The relationship between flow and differential pressure is factory

calibrated. Ambient temperature is measured to compensate for flow differences

with temperature. The EFC also is used to control the state of the helium cutoff

valve at the manifold. This valve is closed if excess getter temperature is

detected or if the helium inlet pressure drops below 20 psi.

Power Input Subsystem and Turbomolecular Pump

Controller

The power input subsystem contains the following circuits and switches:

•

Main power switch

•

SERVICE

switch

•

Line

voltage

switches

25 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...