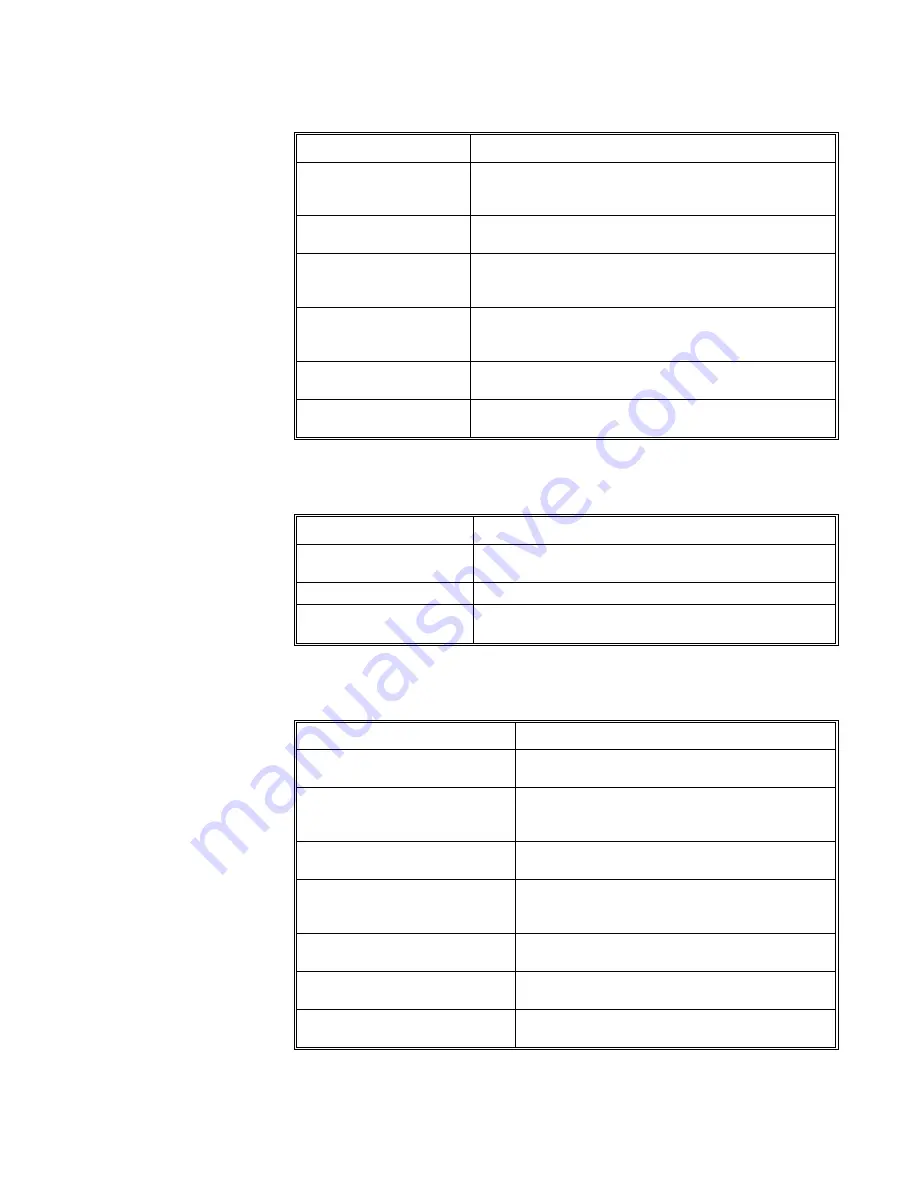

Lack of Peak Size Reproducibility

Possible Cause

Solution

Leaking or partially

plugged syringe

Visually check that the syringe is pulling up the sample.

Check that the nut is tight. Flush the syringe with solvent.

Replace the syringe.

Leak at the septum

Replace the septum regularly and ensure that the septum

nut is tight.

Improper installation of

column in the injector, or a

leak at the column inlet

Check the installation of the column in the injector. Tighten

the capillary column nut.

Sample is being absorbed

by active surfaces in the

injector or column

Change the injector insert. Remove the front 15 cm of the

column, or replace the column.

Incomplete vaporization of

sample in the injector

Increase the injector temperature.

Injector splits too soon.

Confirm that the switch time is chromatographically

optimized.

Correcting Peak Splitting (Particularly for Low

Boilers)

Possible Cause

Solution

Sample flashing in injector

simulating two injections

Lower the injection temperature.

Column is cracked

Re-cut and install the column.

A piece of septum is stuck

in the injector insert.

Replace the insert and septum.

Correcting Extra, Unexpected Peaks in the

Chromatogram

Possible cause

Solution

Septum bleed

Use high-temperature, low-bleed septa. Make sure

that the septum purge flow is set correctly.

Impurities from the sample vials

(e.g., plasticizers present)

Confirm that this is indeed the case by running a

solvent blank with a new syringe. Use certified

sample vials, and keep the samples refrigerated.

Impurities from the carrier gas

present

Install or replace the carrier gas filters.

Injector or GC pneumatics

contaminated

Remove the column from the injector and bake it

out at elevated temperature, (e.g., 350 °C) using a

split vent flow of at least 20 mL/min.

Impurities present in the sample

Confirm that this is indeed the case by running a

blank or standard.

Solvents are extracting impurities

from the septum.

Switch to a new septum type, lower the injection

temperature, or reduce the injection volume.

Impurities present in syringe wash

solvent

Use high purity grade solvents.

112 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...