Helium Flow

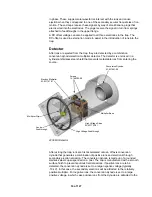

In internal ionization and hybrid mode, helium damping gas is provided to the

trap through the GC column flow. In external ionization mode, the helium

damping gas must be provided separately. Helium enters through a Swagelok®

fitting in the back of the instrument. It is then immediately routed through an

electronic flow controller (EFC) that maintains a constant flow, set through the

workstation in the Module Attributes tab dialog in Manual Control. The EFC

measures the pressure drop across the flow path and then adjusts the position of

an electronically controlled valve to keep the proper flow (see “Electronic Flow

Control” on page 25). After passing through the EFC, the helium flows through a

heated getter to remove water and other contaminants from the system. The

getter normally operates at about 400 °C.

It is critical to run only helium through the getter. Running air or any oxidizing

gases may destroy the getter and result in hazardously high temperatures and

fire.

Helium enters the vacuum manifold through a solenoid valve on the side of the

vacuum manifold. The controller board monitors the temperature of the getter on

a continuous basis. If high temperature, loss of inlet pressure or vacuum failure is

observed, the controller shuts off flow of helium on both sides of the getter.

Calibration Gas Flow

The calibration compound is perfluorotributylamine (PFTBA) or C

12

F

27

N, also

known as fluorocarbon-43 (FC-43). A small glass vial inside the front door of the

4000 MS holds the compound. The flow of calibration gas into the manifold is set

manually via a needle valve. The needle valve is in a block below the CI reagent

needle valve inside the front door of the 4000 MS. The MS Workstation controls

the opening and closing of a three-way solenoid-operated valve downstream of

the needle valve. When the Cal Gas flow is off, a vacuum is placed on the vial,

by way of a line connected to the foreline elbow, to prevent a pressure build up

that would result in a pulse of calibrant when the gas is turned on.

The CI Reagent Gas Flow

The CI reagent enters the system through a solenoid valve on the back of the

instrument. It then passes through a restrictor and second solenoid valve that is

in the same block, on the side of the manifold, as the helium solenoid valve. A

line to the roughing elbow is attached to the CI line to pump away some of the

reagent to prevent pressure pulses when the CI is turned on. The CI control

needle valve controls the flow in this vacuum line that in turn controls the flow of

reagent into the source by changing the split ratio. After passing through the

solenoid valve, the flow passes through the magnet structure inside the vacuum

manifold. In the case of Internal Chemical Ionization, the reagent then flows into

the entire manifold. In the case of External Chemical ionization, the flow is routed

directly into the CI source volume.

20 of 127

Summary of Contents for 4000 GC

Page 4: ......

Page 40: ...6 of 127...

Page 77: ...3 Check source connection pins for proper alignment and straighten as necessary 43 of 127...

Page 124: ...90 of 127...

Page 148: ...114 of 127...