CGAD-SVN02C-EN

28

Motor with Open Coil Winding

a. Open the system's disconnect.

b. Remove the hook-up wires on the

compressor terminals.

c. Touch the terminals of an ohmmeter

on each combination of two

terminals. Not only will it show

continuity, but the resistance in each

set of windings should be

substantially the same.

Grounded Motors and Windings

a. Turn off the system's general

switch.

b. Put a hook-up wire from a

megohmmeter touching a metal

(ground wire).

c. Touch the other hook-up wire on

each of the motor's terminals, one at

a time.

Maintenance

Procedures

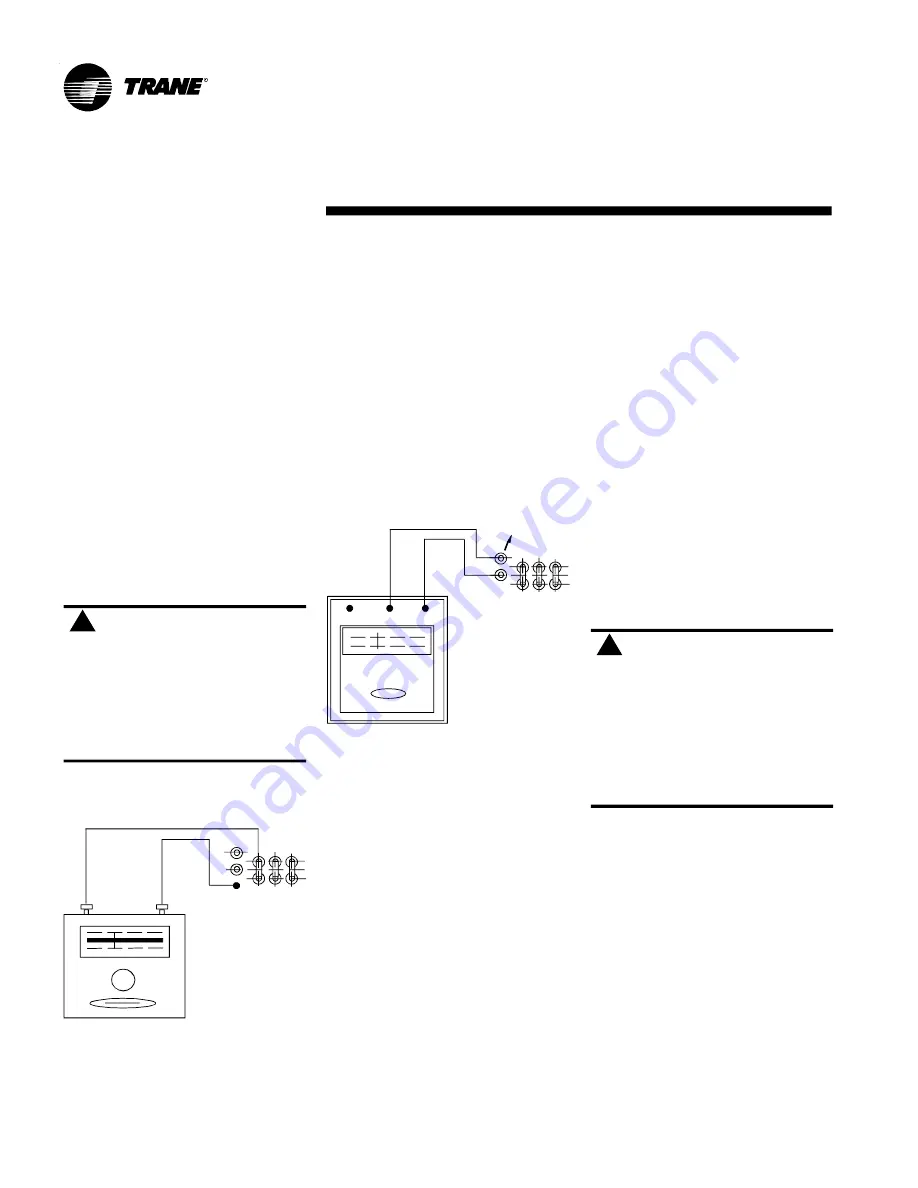

Fig. 10 - Indication for measuring

ohmic resistance

Fig. 11 - Indication of Megohmmeter

Measuring

The electric measurements above

should be done with the system's

general switch turned off.

Never use direct voltage on the

thermistor-type protector. This will

destroy it immediately.

Acceptable readings considered

safe to start up the compressor

should not be less than 1,000 ohms

per Volt of the motor's nominal

voltage.

Example:

Compressor of:

- 230 volts - 230,000 ohms

- 460 volts - 460,000 ohms

In general it is best to use a

megohmmeter of 500 Volts, DC

to test the insulation of the

compressor's motor coils. The use

of megohmmeters with a voltage

greater than 500 volts is not

recommendable for motors with

insulation less than 600 Volts

because, because they could damage

them.

Note: 1 megohm = 1,000,000 ohms.

The markings in general should be

within the range that goes from 1

megohm to infinite. If levels lower than

those above are found, the

compressor should be evacuated and

completely dehydrated and then break

the vacuum and elevate the pressure

to a positive level with refrigerant.

Clean the terminal plate. Then

measure again. If a low insulation

continues to be shown, a grounded

winding is recommended.

Voltage

Check the voltage at the compressor's

terminals while the system is working.

Checking the Insulation of the Motor

and Protection of the Coil

a. Use a megohmmeter of at least 500

V

- Measure insulation between phases

and casing

- Same between phases

b. Ohmic resistance

- Wheatstone bridge or precision

Ohmmeter (1.5 V)

- Thermistors: 90-750 ohms

- Thermostats: + - 1.0 ohm

CAUTION:

!

Never use a megohmmeter or apply

voltage to the motor coil when the

compressor is in vacuum. This could

damage the motor's coiling. Do not apply

the megohmmeter directly on the

terminals of the thermistor or

thermostat.

!

WARNING!

Because the motor acts as a

capacitor when the voltage is

applied, the motor terminals should

be grounded to the compressor's

casing during 60 seconds after the

test has been done. This will lower

the residual voltage in the motor that

could result in a severe electric

shock.

!

!

Summary of Contents for CGAD020

Page 36: ...CGAD SVN02C EN 36 Wiring Diagram Fig 17 Power and command wiring diagram CGAD 020C Sheet 1 2...

Page 52: ...CGAD SVN02C EN 52 Wiring Diagram Fig 33 Power and command wiring diagram CGAD 070C Sheet 1 2...

Page 60: ...CGAD SVN02C EN 60 Wiring Diagram Fig 41 Power and command wiring diagram CGAD100 Part I...

Page 61: ...CGAD SVN02C EN 61 Wiring Diagram Fig 42 Power and command wiring diagram CGAD100 Part II...

Page 62: ...CGAD SVN02C EN 62 Wiring Diagram Fig 43 Power and command wiring diagram CGAD100 Part III...

Page 63: ...CGAD SVN02C EN 63 Wiring Diagram Fig 44 Layout diagram CGAD100...

Page 64: ...CGAD SVN02C EN 64 Wiring Diagram Fig 45 Power and command wiring diagram CGAD120 Part I...

Page 65: ...CGAD SVN02C EN 65 Wiring Diagram Fig 46 Power and command wiring diagram CGAD120 Part II...

Page 66: ...CGAD SVN02C EN 66 Wiring Diagram Fig 47 Power and command wiring diagram CGAD 120 Part III...

Page 67: ...CGAD SVN02C EN 67 Wiring Diagram Fig 48 Layout diagram CGAD 120...

Page 68: ...CGAD SVN02C EN 68 Wiring Diagram Fig 49 Power and command wiring diagram CGAD150 Part I...

Page 69: ...CGAD SVN02C EN 69 Wiring Diagram Fig 50 Power and command wiring diagram CGAD150 Part II...

Page 70: ...CGAD SVN02C EN 70 Wiring Diagram Fig 51 Power and command wiring diagram CGAD150 Part III...

Page 71: ...CGAD SVN02C EN 71 Fig 52 Layout diagram CGAD150 Wiring Diagram...

Page 72: ...CGAD SVN02C EN 72 Wiring Diagram Fig 53 Layout diagram CGAD 100 125 150 with optionals...