CGAD-SVN02C-EN

27

Maintenance

Procedures

ATTENTION:

Mechanical cleaning must not be

performed in the Evaporator, once the

water flows through the vessel and

refrigerant gas flows inside the tubing.

Chemical Cleaningn

Chemical cleaning is the most satisfactory

means of removing deposits from the

tubes. In this treatment, the deposits are

dissolved and taken away by the

circulation of a chemical solution. The

condenser is made up of copper, steel,

and cast iron. With this information any

company that is specialized in water

treatment will be able to recommend a

chemical product to be used for this

purpose. If it is not possible to contract a

water treatment service, a chemical

product supplier could be consulted.

Cleaning on Evaporator

The evaporator is part of a closed circuit

that should not accumulate any amount of

encrustations or sediments.

The speed of the accumulation of layers

will increase with high temperature of

condensation and by water with a high

ratio of minerals. The formation of layers of

sediments in the tubes of condenser

water occurs due to a decrease in the flow

of water, a small difference in temperature

between the entering and leaving water,

and the condensing temperature that is

abnormally high. The condenser needs to

be always free of sediments in order to

keep its maximum efficiency. Even a very

fine layer along the surfaces of the tube

can diminish significantly the condenser's

heat transfer capacity.

CAUTION:

All the tests done on the pressure

regulator should be done with reliable

pressure gauges. These safety devices

are calibrated at the factory and sealed. If

violated, the warranty will be void.

!

The internal parts of the evaporator are

made of steel, polypropylene, and copper.

Do not use cleaning products that can

damage these components.

CAUTION:

!

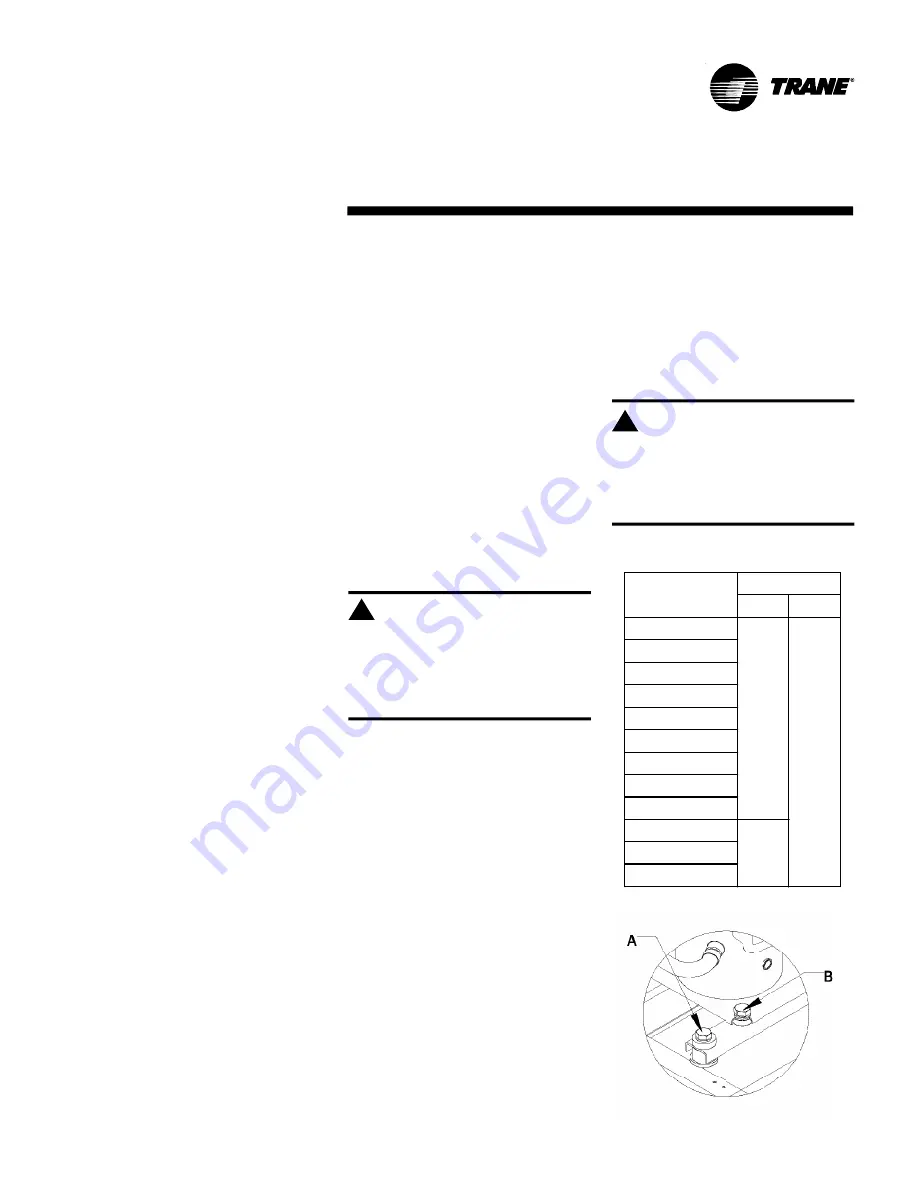

A

B

CGAD 020

CGAD 025

CGAD 030

CGAD 040

CGAD 050

CGAD 060

CGAD 070

CGAD 080

CGAD 090

CGAD 100

CGAD 120

CGAD 150

EQUIPMENT

TORQUE

21 Nm

15 Nm

40 Nm

"All the materials used in the external

circulation system, quantity of cleaning

material, duration of the cleaning period,

and any other safety precautions needed

for handling the cleaning agent should be

approved by the company supplying the

chemical products used to execute the

service.

Specification of torque in pad bolts.

Summary of Contents for CGAD020

Page 36: ...CGAD SVN02C EN 36 Wiring Diagram Fig 17 Power and command wiring diagram CGAD 020C Sheet 1 2...

Page 52: ...CGAD SVN02C EN 52 Wiring Diagram Fig 33 Power and command wiring diagram CGAD 070C Sheet 1 2...

Page 60: ...CGAD SVN02C EN 60 Wiring Diagram Fig 41 Power and command wiring diagram CGAD100 Part I...

Page 61: ...CGAD SVN02C EN 61 Wiring Diagram Fig 42 Power and command wiring diagram CGAD100 Part II...

Page 62: ...CGAD SVN02C EN 62 Wiring Diagram Fig 43 Power and command wiring diagram CGAD100 Part III...

Page 63: ...CGAD SVN02C EN 63 Wiring Diagram Fig 44 Layout diagram CGAD100...

Page 64: ...CGAD SVN02C EN 64 Wiring Diagram Fig 45 Power and command wiring diagram CGAD120 Part I...

Page 65: ...CGAD SVN02C EN 65 Wiring Diagram Fig 46 Power and command wiring diagram CGAD120 Part II...

Page 66: ...CGAD SVN02C EN 66 Wiring Diagram Fig 47 Power and command wiring diagram CGAD 120 Part III...

Page 67: ...CGAD SVN02C EN 67 Wiring Diagram Fig 48 Layout diagram CGAD 120...

Page 68: ...CGAD SVN02C EN 68 Wiring Diagram Fig 49 Power and command wiring diagram CGAD150 Part I...

Page 69: ...CGAD SVN02C EN 69 Wiring Diagram Fig 50 Power and command wiring diagram CGAD150 Part II...

Page 70: ...CGAD SVN02C EN 70 Wiring Diagram Fig 51 Power and command wiring diagram CGAD150 Part III...

Page 71: ...CGAD SVN02C EN 71 Fig 52 Layout diagram CGAD150 Wiring Diagram...

Page 72: ...CGAD SVN02C EN 72 Wiring Diagram Fig 53 Layout diagram CGAD 100 125 150 with optionals...