CGAD-SVN02C-EN

8

Dispatch and Handling

1. The CGAD Cooling units leave the plant

ready to be installed, tested as needed,

and with the correct level of oil and

refrigerant for operation.

2. When the unit arrives, compare all the

data on the plate with the information on

the order and invoice.

3. In order to receive the unit, run a visual

check on all the components, tubing, and

connections in order to make sure that

there are no dents or leaks caused by

handling during transportation. If there are

any problems, notify the transportation

company and Trane do Brasil immediately.

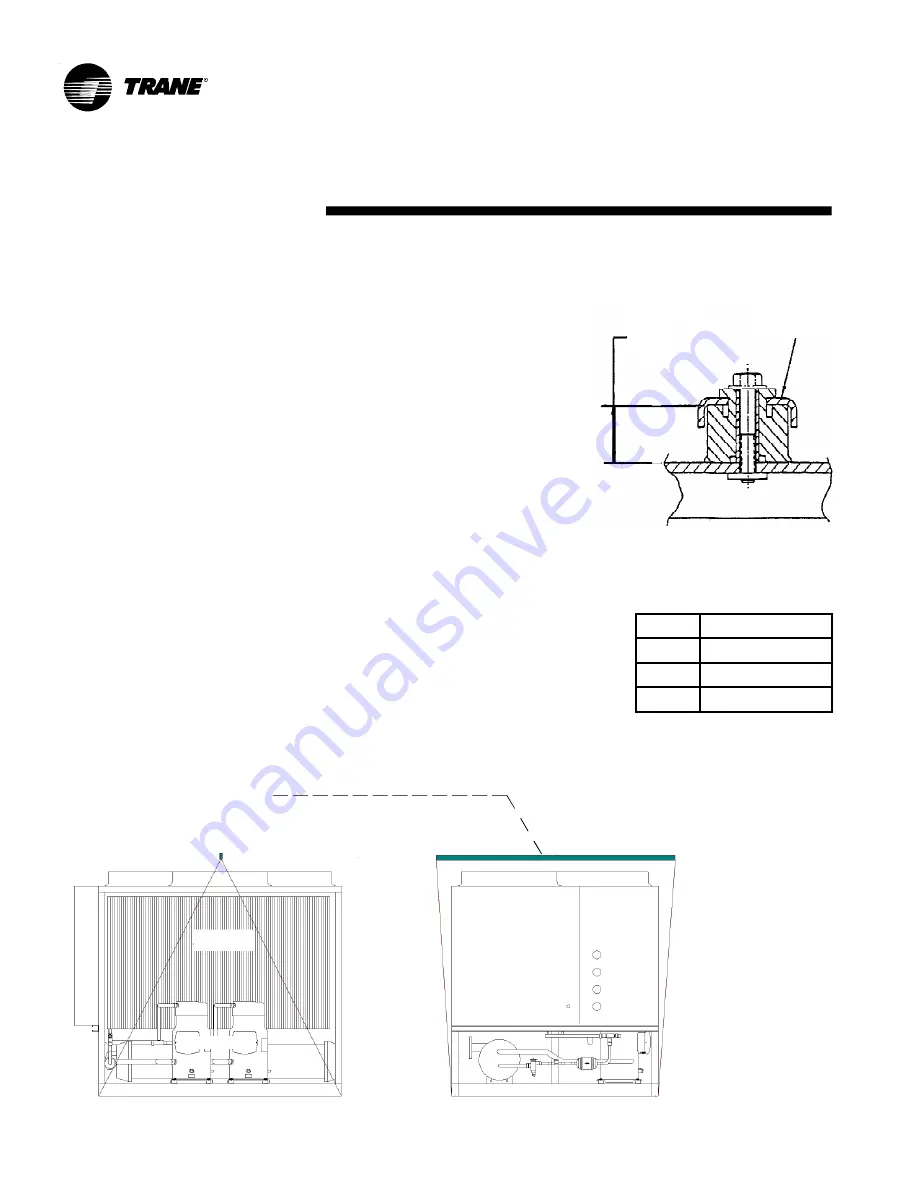

4. The CGAD Cooling units come with

hoisting supports along both sides of the

unit's profile made up of four holes. Put the

hoisting cables through the holes and set

extension bars between the cables on the

top part of the unit (fig. 2). This way, when

the equipment is hoisted correctly, it will

remain in its center of gravity. The loading

weights are shown on table 2.

5. The chains, ropes, or steel cables

should not touch the equipment.

6. During transportation, do not tip or lean

the equipment more than 15° from the

vertical position.

7. The compressors are fixed to their

support tracks with the bolts from the

rubber pads themselves and they leave

the plant tight for protection against

movements that could cause the tubing to

break. The operation and loading position

in this type of pad is the same.

Support and Fastening Base

1. In order to fix the CGAD unit in place,

there must be a support base that is

perfectly level and smooth. Also make sure

that the location for the unit is sufficiently

resistant to withstand its weight and

absorb the vibrations of the unit.

2. We recommend using skids or vibration

arrestors under the unit's support feet. The

rubber pad-type vibration arrestors should

be installed between the unit's feet and the

base surface. If the equipment is installed

on top of cement slab or roof, spring-type

vibration arrestors should be purchased.

We do not recommend the use of shock

absorbers of springs vibration.

3. Mark the support points on the flooring

and be careful when moving the unit

horizontally and vertically.

Transportation

and Movement

U-Beam 3” x 1 1/2” x 0.25” x 100”

Fig. 02 - Fastening the compressor

Fig. 03 - Transportation and movement instruction

CONDENSER

COIL

COMPRESSORS

ELECTRICAL

PANEL

PRESSURE

GAUGES

Model

Dimension "A"

020

57''

025-030

71''

040-090

78,8'

Working

height

Base

Compressor

Summary of Contents for CGAD020

Page 36: ...CGAD SVN02C EN 36 Wiring Diagram Fig 17 Power and command wiring diagram CGAD 020C Sheet 1 2...

Page 52: ...CGAD SVN02C EN 52 Wiring Diagram Fig 33 Power and command wiring diagram CGAD 070C Sheet 1 2...

Page 60: ...CGAD SVN02C EN 60 Wiring Diagram Fig 41 Power and command wiring diagram CGAD100 Part I...

Page 61: ...CGAD SVN02C EN 61 Wiring Diagram Fig 42 Power and command wiring diagram CGAD100 Part II...

Page 62: ...CGAD SVN02C EN 62 Wiring Diagram Fig 43 Power and command wiring diagram CGAD100 Part III...

Page 63: ...CGAD SVN02C EN 63 Wiring Diagram Fig 44 Layout diagram CGAD100...

Page 64: ...CGAD SVN02C EN 64 Wiring Diagram Fig 45 Power and command wiring diagram CGAD120 Part I...

Page 65: ...CGAD SVN02C EN 65 Wiring Diagram Fig 46 Power and command wiring diagram CGAD120 Part II...

Page 66: ...CGAD SVN02C EN 66 Wiring Diagram Fig 47 Power and command wiring diagram CGAD 120 Part III...

Page 67: ...CGAD SVN02C EN 67 Wiring Diagram Fig 48 Layout diagram CGAD 120...

Page 68: ...CGAD SVN02C EN 68 Wiring Diagram Fig 49 Power and command wiring diagram CGAD150 Part I...

Page 69: ...CGAD SVN02C EN 69 Wiring Diagram Fig 50 Power and command wiring diagram CGAD150 Part II...

Page 70: ...CGAD SVN02C EN 70 Wiring Diagram Fig 51 Power and command wiring diagram CGAD150 Part III...

Page 71: ...CGAD SVN02C EN 71 Fig 52 Layout diagram CGAD150 Wiring Diagram...

Page 72: ...CGAD SVN02C EN 72 Wiring Diagram Fig 53 Layout diagram CGAD 100 125 150 with optionals...