CGAD-SVN02C-EN

18

Operational

Conditions

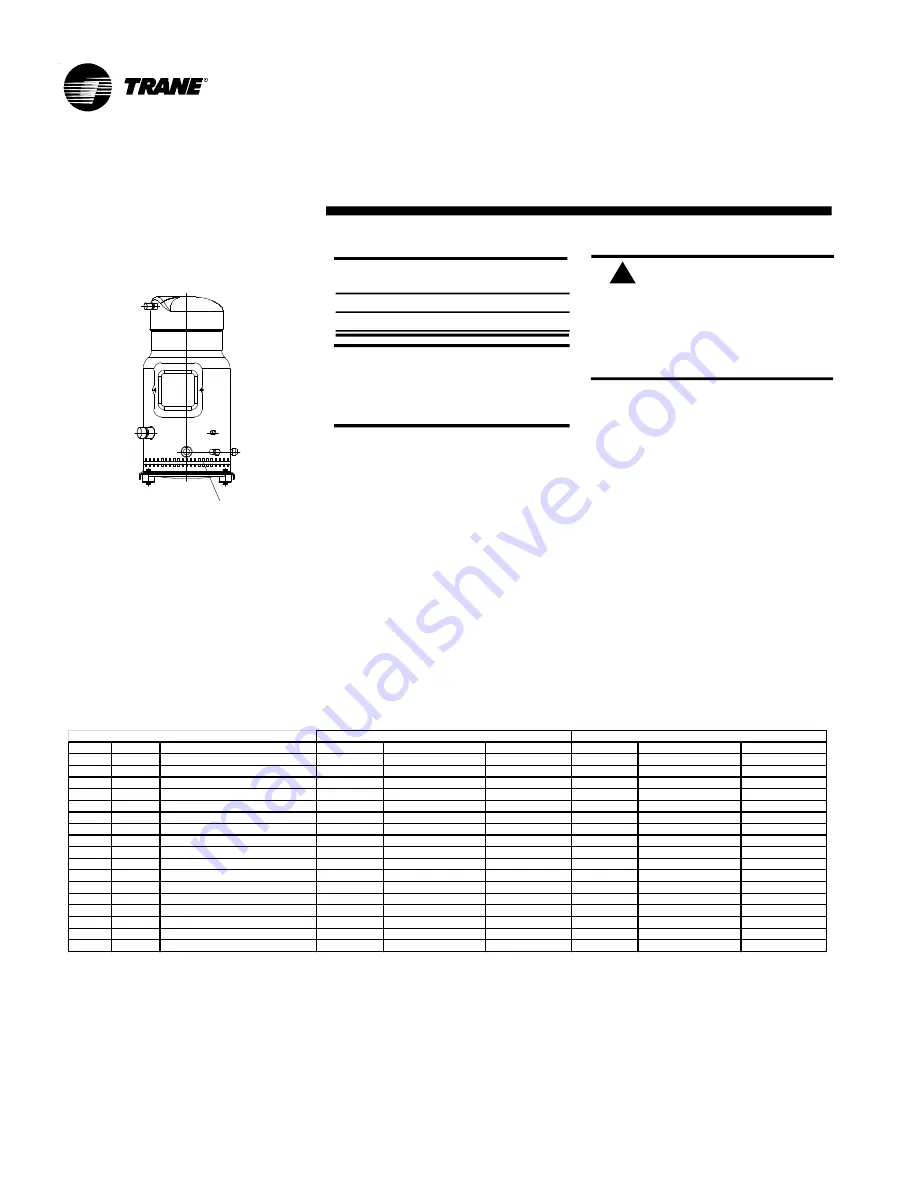

Fig.08 - Resistance of crankcase

Recommended for position fixing

Crankcase Resistance

Trane recommends the use of crankcase

when the load of the system refrigerant

load exceeds the refrigerant compressor

limit (RCL). The needs of crankcase

resistance are directly related to the

possibility of liquid migration to the

compressor, and consequently causing

poor lubrication of it. Migration can occur

during long periods of compressor

shutdown (over 8 hours). The crankcase

resistance is recommended to eliminate

the liquid migration when these downtime

long periods.The crankcase resistance

must be installed on the compressor

housing and below the removal oil point.

The crankcase resistance must remain

energized while the compressor is off.

Attention:

The strength of crankcase must be

energized at least 12 hours before the

startup of the compressor (with the service

valves open) and should be maintained

until the compressor energized startup.

!

This will prevent the dilution of oil and the

bearings overload in the initial compressor

starts. When the compressor is off, the

crankcase temperature should be kept at

least 10°C above the refrigerant

temperature in the suction side (low

pressure side). This requirement ensures

that the refrigerant will not be retained in

the compressor crankcase. Tests can be

done to ensure that the appropriate

temperature of the oil is maintained below

the ambient conditions (temperature and

wind).

Therefore, for a temperature below -5°C

and an over 5m/s wind speed, it is

recommended that the resistors be

thermally isolated to limit the energy loss to

the environment.

Notes:

1)oilload, refers tothe total filed replacement.

2)In retrofit ormaintenanceprocedures, the idealisthat there is no mineral oilandsynthetic oilmixture! Themaximum percentage ofmixture of mineral andsyntheticoil is5%.Forexample, fora retrofitoperation ofR407C,

when the chillerwill beloaded with 20 liters of syntheticoilwill be tolerateinthesystem up to 1 literof mineraloil. Itapplies the same ruleintheconversion ofsyntheticoilformineral oil.

IMPORTANT

Temperatures

Superheating

5° C to 10°C

Subcooling

6° C to 12° C

Table 04 - load and Refrigerant Oil

RECOMMENDATION

The oil recommended by Trane do Brasil

to be used on the CGAD units is

TRANE

OIL 48

.

M ODEL REFRIG.

OLEO RECOM M ENDED

COM P R.1

CARGO REFRIG.(Kg) CARGO OLEO (L)

COM P R.2

CARGO REFRIG.(Kg) CARGO OLEO (L)

CGAD020

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

2xSZ125

18,5

7,6

CGAD025

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

SZ125/SZ185

22,0

10,0

CGAD030

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

2xSZ185

24,0

12,4

CGAD040

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

2xSZ125

18,0

7,6

2xSZ125

18,0

7,6

CGAD050

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

SZ125/SZ185

22,5

10,0

SZ125/SZ185

22,5

10,0

CGAD060

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

2xSZ185

27,0

12,4

2xSZ185

27,0

12,4

CGAD070

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

SZ185

31,5

13,8

SZ185

31,5

13,8

CGAD080

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

SZ125

36,0

16,2

SZ125

36,0

16,2

CGAD090

R407C

TRANE OIL-00048 ouDANFOSS 160SZ

3xSZ185

40,5

18,6

3xSZ185

40,5

18,6

CGAD100

R407C

TRANE OIL-00048 ou DANFOSS 320 SZ

2x SY300

41,0

17,5

2 xSY300

41,0

17,5

CGAD120

R407C

TRANE OIL-00048 ou DANFOSS 320 SZ

3x SY240

66,0

26,0

3 xSY240

66,0

26,0

CGAD150

R407C

TRANE OIL-00048 ou DANFOSS 320 SZ

3x SY300

66,0

26,0

3 xSY300

66,0

26,0

CGAD100

R407C

COPELAND 3MAF (*)

2XZR300KCE

41,0

11,2

2XZR300KCE

41,0

11,2

CGAD100

R407C

COPELAND 3MAF (*)

2XZR310KCE

41,0

11,2

2XZR310KCE

41,0

11,2

CGAD120

R407C

COPELAND 3MAF (*)

3XZR250KCE

66,0

13,2

3XZR250KCE

66,0

13,2

CGAD150

R407C

COPELAND 3MAF (*)

3XZR300KCE

66,0

16,8

3XZR300KCE

66,0

16,8

CGAD150

R407C

COPELAND 3MAF (*)

3XZR310KCE

66,0

16,8

3XZR310KCE

66,0

16,8

CIRCUIT 01

CIRCUIT 02

Summary of Contents for CGAD020

Page 36: ...CGAD SVN02C EN 36 Wiring Diagram Fig 17 Power and command wiring diagram CGAD 020C Sheet 1 2...

Page 52: ...CGAD SVN02C EN 52 Wiring Diagram Fig 33 Power and command wiring diagram CGAD 070C Sheet 1 2...

Page 60: ...CGAD SVN02C EN 60 Wiring Diagram Fig 41 Power and command wiring diagram CGAD100 Part I...

Page 61: ...CGAD SVN02C EN 61 Wiring Diagram Fig 42 Power and command wiring diagram CGAD100 Part II...

Page 62: ...CGAD SVN02C EN 62 Wiring Diagram Fig 43 Power and command wiring diagram CGAD100 Part III...

Page 63: ...CGAD SVN02C EN 63 Wiring Diagram Fig 44 Layout diagram CGAD100...

Page 64: ...CGAD SVN02C EN 64 Wiring Diagram Fig 45 Power and command wiring diagram CGAD120 Part I...

Page 65: ...CGAD SVN02C EN 65 Wiring Diagram Fig 46 Power and command wiring diagram CGAD120 Part II...

Page 66: ...CGAD SVN02C EN 66 Wiring Diagram Fig 47 Power and command wiring diagram CGAD 120 Part III...

Page 67: ...CGAD SVN02C EN 67 Wiring Diagram Fig 48 Layout diagram CGAD 120...

Page 68: ...CGAD SVN02C EN 68 Wiring Diagram Fig 49 Power and command wiring diagram CGAD150 Part I...

Page 69: ...CGAD SVN02C EN 69 Wiring Diagram Fig 50 Power and command wiring diagram CGAD150 Part II...

Page 70: ...CGAD SVN02C EN 70 Wiring Diagram Fig 51 Power and command wiring diagram CGAD150 Part III...

Page 71: ...CGAD SVN02C EN 71 Fig 52 Layout diagram CGAD150 Wiring Diagram...

Page 72: ...CGAD SVN02C EN 72 Wiring Diagram Fig 53 Layout diagram CGAD 100 125 150 with optionals...