CGAD-SVN02C-EN

77

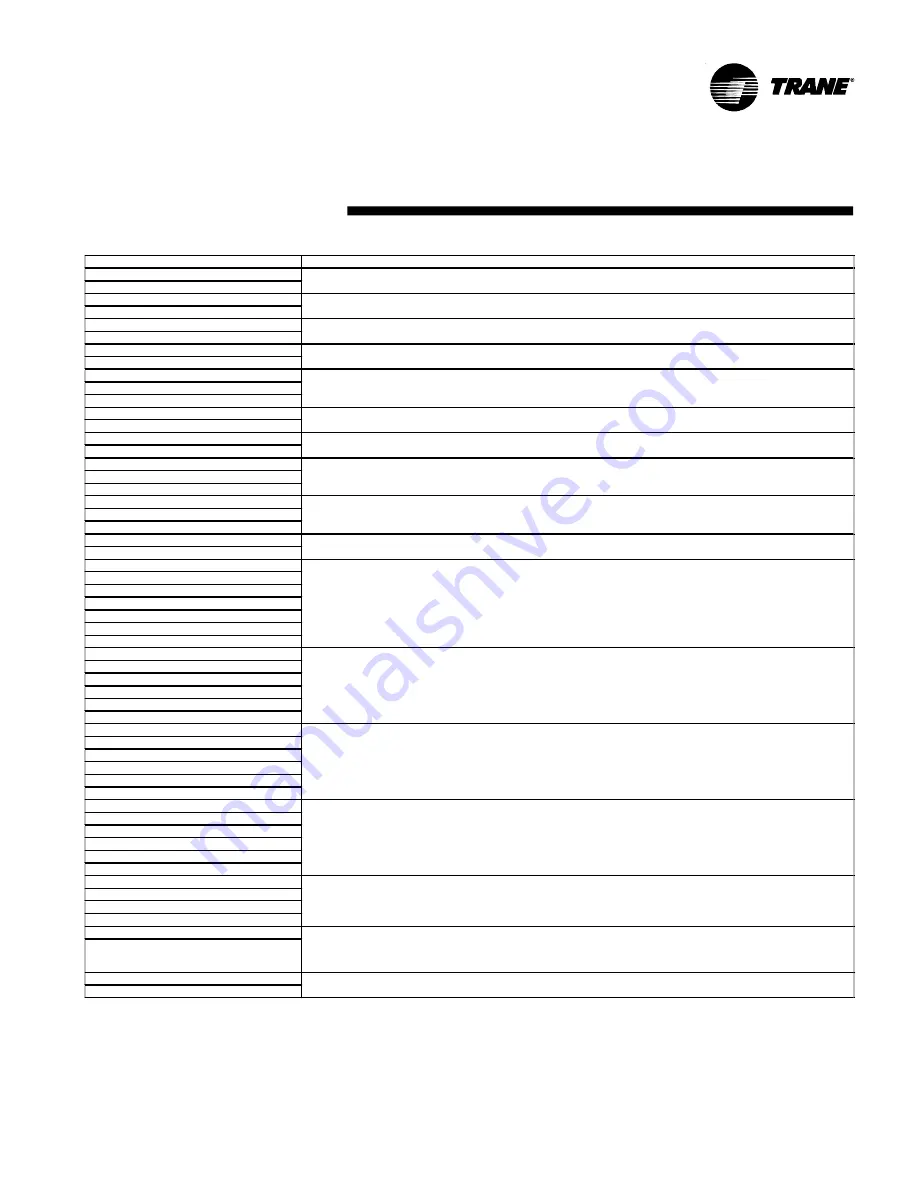

M essag e

D escr i p t io n o f Pr o b l em

Err2: RAM Pat tern 1Failure

(Failure in t he Controller's M emory)

Err2: RAM Patt ern 2 Failure

(Failure in t he Controller's M emory)

Err2: RAM A ddr Test # 1Failure

(Failure in t he Controller's M emory)

Err2: RAM Addr Test # 2 Failure

(Failure in t he Controller's M emory)

No Applicat ion Present

Please Load A pplicat ion...

M P: Invalid Configurat ion

M P Applicat ion M emory CRC Error

App Present . Running Self test .…

Self test Passed

App Present . Running Self test .…

Err3: CRC Failure

(Failure wit h the Selft est )

A V alid Conf iguration is not Present

Err4: UnHandled Interrupt

Rest art Timer:

[ 3 sec count down t imer]

Err5: Operat ing Syst em Error

Rest art Timer:

[ 3 sec count down t imer]

(Operat ional Syst em Error)

Err6: Watch Dog Timer Error

Rest art Timer:

[ 3 sec count down t imer]

Err7: Unknown Error

Rest art Timer:

[ 3 sec count down t imer]

Err8: Held in Boot by User Key Press

[ 3 sec count down t imer]

Converter M ode

Programming M ode

A command was received by t he cont roller, by TechView, t o erase t he cont ent from its non-volatile memory and receive t he

programming that the user want s t o t ransfer.

An error was det ect ed in t he t ime cont rol while the equipment operat ed normally. When t he count er reaches 0 seconds, t he cont roller

will reset t he diagnostics and prepare the equipment to start up again.

An unknown error was det ected while t he equipment operated normally. When the count er reaches 0 seconds, the controller will reset

the diagnost ics and prepare the equipment t o start up again.

The request t o suspend the controller's soft ware boot was det ect ed, which was made by t he user. This mode can be used t o repair

sof t ware error in t he application code. Turn the controller off and t hen back on if this request was made accident ally.

A command was received by t he cont roller, by TechView, t o hold the normal operation and act uat e t he Converter M ode, which will

allow TechView t o communicate wit h all t he devices t hat belong to the control syst em.

Detected a valid application but also f ound a failure during self t est . The appropriate applicat ion for t he equipment model should be

loaded again using TechView. If t he f ailure persist s, t he cont roller (DynaView) must be replaced.

A valid configuration was not found in t he cont roller. The appropriat e configuration f or t he equipment model should be loaded using

TechView.

An unsupported interrupt ion occurred during the processing of the applicat ion. This normally causes the equipment t o shut down.

When t he count er reaches 0 seconds, t he cont roller will reset the diagnost ics and prepare the equipment t o start up again.

An operat ional error was det ected while t he equipment operated normally. When the count er reaches 0 seconds, the controller will

reset the diagnost ics and prepare the equipment t o start up again.

The cont roller is not loaded wit h t he application soft ware to make it possible t o cont rol the equipment 's devices. It will be necessary

to load up t he soft ware on the cont roller for adequat e applicat ion f or t he equipment 's model using t he Tech V sof tware.

The cont roller's configuration is not adequat e t o use t oget her wit h the sof tware inst alled in t he cont roller.

The sof t ware's selft est det ect ed an error. Possible causes: The sof tware of applicat ion was not complet ely loaded, t here was a loss

of part of t he sof t ware, or the controller has a def ect . Try reprogramming the cont roller.

Detected a valid application and carried out the self t est successfully.

An error was det ect ed during memory test . Unplug the cont roller for some seconds and then t urn it on again. If the error persists, the

cont roller (DynaView) must be replaced.

An error was det ect ed during memory test . Unplug the cont roller for some seconds and then t urn it on again. If the error persists, the

cont roller (DynaView) must be replaced.

An error was det ect ed during memory test . Unplug the cont roller for some seconds and then t urn it on again. If the error persists, the

cont roller (DynaView) must be replaced.

An error was det ect ed during memory test . Unplug the cont roller for some seconds and then t urn it on again. If the error persists, the

cont roller (DynaView) must be replaced.

Diagnostics

CH 530

Summary of Contents for CGAD020

Page 36: ...CGAD SVN02C EN 36 Wiring Diagram Fig 17 Power and command wiring diagram CGAD 020C Sheet 1 2...

Page 52: ...CGAD SVN02C EN 52 Wiring Diagram Fig 33 Power and command wiring diagram CGAD 070C Sheet 1 2...

Page 60: ...CGAD SVN02C EN 60 Wiring Diagram Fig 41 Power and command wiring diagram CGAD100 Part I...

Page 61: ...CGAD SVN02C EN 61 Wiring Diagram Fig 42 Power and command wiring diagram CGAD100 Part II...

Page 62: ...CGAD SVN02C EN 62 Wiring Diagram Fig 43 Power and command wiring diagram CGAD100 Part III...

Page 63: ...CGAD SVN02C EN 63 Wiring Diagram Fig 44 Layout diagram CGAD100...

Page 64: ...CGAD SVN02C EN 64 Wiring Diagram Fig 45 Power and command wiring diagram CGAD120 Part I...

Page 65: ...CGAD SVN02C EN 65 Wiring Diagram Fig 46 Power and command wiring diagram CGAD120 Part II...

Page 66: ...CGAD SVN02C EN 66 Wiring Diagram Fig 47 Power and command wiring diagram CGAD 120 Part III...

Page 67: ...CGAD SVN02C EN 67 Wiring Diagram Fig 48 Layout diagram CGAD 120...

Page 68: ...CGAD SVN02C EN 68 Wiring Diagram Fig 49 Power and command wiring diagram CGAD150 Part I...

Page 69: ...CGAD SVN02C EN 69 Wiring Diagram Fig 50 Power and command wiring diagram CGAD150 Part II...

Page 70: ...CGAD SVN02C EN 70 Wiring Diagram Fig 51 Power and command wiring diagram CGAD150 Part III...

Page 71: ...CGAD SVN02C EN 71 Fig 52 Layout diagram CGAD150 Wiring Diagram...

Page 72: ...CGAD SVN02C EN 72 Wiring Diagram Fig 53 Layout diagram CGAD 100 125 150 with optionals...