7-74

HDW-750/750CE V1

Installation

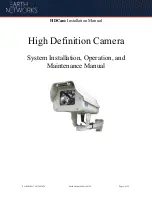

5. Installing the S-tension regulator

assembly

Insert the bearing holder block of the new S-

tension regulator assembly into the reference hole

and fix it with the two precision screws in the order

starting from

1

then

2

.

The standard tightening torque value :

10

x

10

_

2

N

.

m (1.0 kgf

.

cm)

6. Installing the S-tension regulator band

assembly

Install the S-tension regulator band assembly.

(Refer to Section 7-8.)

7. Installing the end sensor assembly

Fix the end sensor assembly with screw.

(Refer to Section 7-15.)

8. Cleaning of tape guide of S-tension

regulator arm (S5)

Clean the S-tension regulator arm (S5) tape guide

using a cleaning cloth moistened with cleaning fluid.

After cleaning, be sure to wipe the cleaning fluid

off the cleaned portions using a dry cleaning cloth.

9. Moving the S3 tape guide

Rotate the manual eject gear (A) clockwise until

the S3 tape guide returns to the original position.

Adjustments after Replacement

10. S-tension regulator operating position

adjustment

(Refer to Section 8-1-2.)

11. FWD back tension adjustment

(Refer to Section 8-1-3.)

12. Tape run adjustment

(Refer to Section 8-2-1.)

13. Capstan add-on recording adjustment

(Refer to Section 10-5-3.)

7-21. S-Tension Regulator Assembly Replacement

Precision screws

M1.4

x

3.5

Reference

hole

S-tension regulator assembly

S5 tape guide

(cleaning)

Bearing holder block

S3 tape guide

1

2