8-18

HDW-750/750CE V1

8-1. Mechanical Adjustment

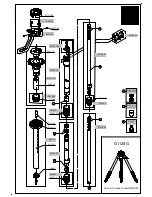

4. T gear assembly adjustment

(1) Remove the T slider assembly.

(Refer to Section 7-33.).

(2) Enter the unit in the threading-end state.

(Confirm that the intermittent gear stops

rotating and the specified portion of the S

gear assembly shown in the illustration, has

fully opened.)

.

When replacing the T slider assembly :

Rotate the manual eject gear (A) counter-

clockwise.

.

When replacing the cam gear assembly :

Rotate the cam gear assembly clockwise.

c

Do not rotate the intermittent gear after the

mechanism has reached the threading end

state. If the intermittent gear is kept rotating,

it will damage the mechanical parts.

T

Manual eject gear (A)

Cam gear assembly

S slider

Open

S gear assembly

Intermittent gear

T

T

T

Parallel pin

(d = 2.0 mm)

Hole of the S slider

assembly

Hole of mechanism

frame

Hole of the

S gear assembly

Fig. 1

Fig. 2

Fig. 3

T gear assembly

T gear assembly

T gear assembly

Intermittent gear

Intermittent

gear

Intermittent

gear

Round

hole

Round hole

Stop washer

(3) Fix the gear chain by inserting the parallel

pin (d = 2.0 mm) from the hole of the S slider

assembly through the S gear assembly’s hole

until it is inserted into the hole of the

mechanism frame. (Fig. 1)

(4) Remove the cam gear. (Refer to Section 7-34.)

(5) Remove the stop washer and remove the

intermittent gear. (Fig. 2)

(6) To adjust coupling between the gears, slip off

and on the T gear assembly or intermittent

gear until the round hole of the T gear

assembly faces right opposite to the round

hole of the intermittent gear. (Fig. 3)

(7) Attach the intermittent gear using the new

stop washer.

(8) Attach the cam gear assembly using the new

stop washer. (Refer to Section 7-34.)

(9) When the adjustment is complete, remove the

parallel pin and attach the T slider assembly.

(Refer to Section 7-33.)