22

IMR01N12-E7

4. SETTING

This chapter describes procedures to set operating conditions of a customer and parameter of various setting

modes.

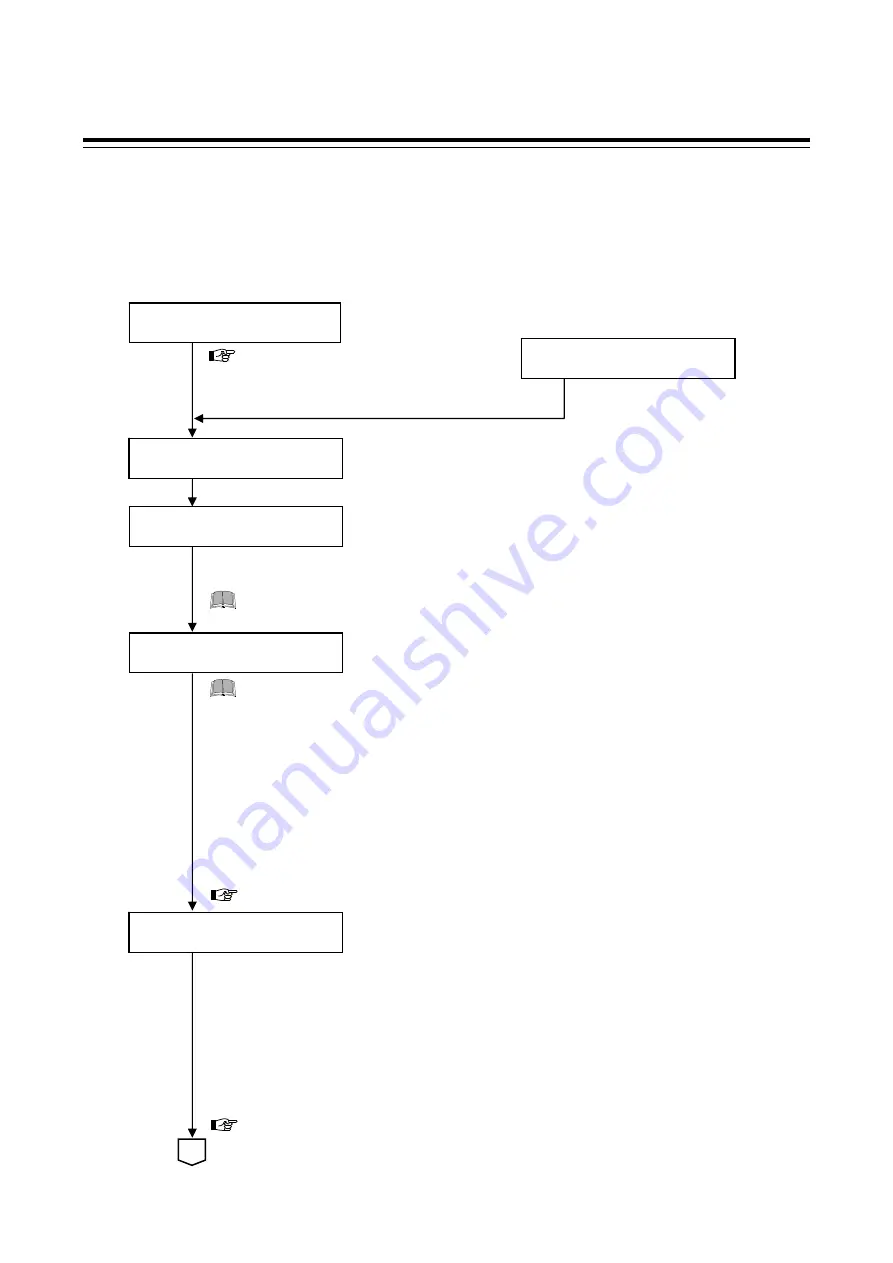

4.1 Setting Procedure to Operation

Conduct necessary setting before operation according to the procedure described below.

Continued on the next page.

Mounting and Wiring

When installing the instrument,

refer to

2. MOUNTING (P. 10)

and

3. WIRING. (P. 13)

Power ON

Change from RUN to STOP

Use the sheet of Appendix C, and

make record of setting data of a

customer.

Factory set value: RUN (Control start)

Press the direct key (R/S) to change the RUN/STOP status from RUN mode to STOP mode.

Setting of operating condition

The parameters for controller’s basic functions in Engineering mode should be changed

according to the application before setting the parameters related to operation.

For details of the Engineering mode, refer to

8. ENGINEERING MODE. (P. 50)

Setup data setting

Set parameters in Setup setting mode:

For details of the Setup setting mode, refer to

7. SETUP SETTING MODE. (P. 42)

Entry to data sheet

Be sure to check the parameters for the following settings and change them according to the

application if necessary. Other parameters should be also changed according to the application.

Input 1:

Input type, Gain setting

*, Presser input range, Linearize type

*, and Shunt resistance output value

Input 2 type (RTD input/voltage input/current input specified when the instrument is ordered)

Power frequency (50 Hz or 60 Hz) [Factory set value: 50 Hz]

Control action (Direct action or Reverse action) [Factory set value: Reverse action]

Output logic selection (Output function assignment from OUT1 to OUT5)

[Factory set value: 1-input controller: 3, 2-input controller: 5]

* Our CZ-100P or CZ-200P

Auto-zero

1, 2

Auto calibration

2

PV bias, PV digital filter, PV ratio, PV low input cut-off

Proportional cycle time for control output (Expect voltage and current output)

Communication (optional)

1

Our CZ-100P or CZ-200P

2

Before execution, it is necessary to rise the temperature of equipment installed with the pressure sensor.

The parameters in Engineering mode which should be set according to the application are settable

only when the controller is in STOP mode.

A