57

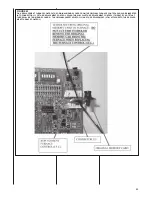

For troubleshooting purposes, follow the

wiring diagram and troubleshooting flow-

chart supplied in this manual and on the

inside of the furnace blower door.

Additionally, the pin designations for the

connector are specified below:

Pin 1 to Inducer High Speed Output.

Pin 2 to Inducer Low Speed Output

Pin 3 is not used.

Pin 4 to Neutral.

NEUTRAL TERMINALS

These terminals connect 115VAC neu-

tral to the furnace control from the input

at the junction box of the furnace.

Additionally, spare terminals are provid-

ed for use with electronic air cleaners,

humidifiers and other accessories as

needed (Check the voltage rating of

your equipment.)

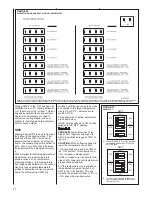

ELECTRONIC AIR CLEAN-

ER (E.A.C.) OUTPUT (J8)

This output is used to energize an elec-

tronic air cleaner. The output will pro-

vide 1.0 amp at 115 VAC. This output is

energized any time the blower motor is

above 40% of maximum airflow capaci-

ty. Airflow below this value is not con-

sidered to be enough for a typical elec-

tronic air cleaner to perform properly.

For 1/2HP motors – Electronic air clean-

er is energized any time the blower is

above 480 CFM (1200 CFM x 0.4)

For 1 HP motors - Electronic air cleaner

is energized any time the blower is

above 800 CFM (2000 CFM x 0.4)

HUMIDIFIER OUTPUT (J8)

These outputs (two) are connected to

the contacts of a control-mounted relay.

In this sense, they are what are called

“dry” contacts. That is, they provide no

voltage, they are only used to close a

circuit. The contacts can be used to

close either a 24VAC or 115VAC circuit

either with a maximum of 1 amp

current.

Details about the humidifier outputs and

wiring diagrams can be found in the

section titled

HUMIDIFICATION AND

DEHUMIDIFICATION of this document.

STEPPER GAS VALVE

CONTROL (J16)

For furnaces equipped with a stepper

modulating gas valve, a five-pin con-

nector is used to control and sense the

gas valve. The valve uses a PWM

(Pulse Width Modulated) signal to con-

trol the firing rate. The duty cycle of

this signal is five percent less than the

expected firing rate. For example, if

the firing rate is 90%, the PWM to (and

from) the valve will be 85% duty cycle.

The connector also provides the

24VAC signal to energize the main

valve solenoid. Reference the wiring

diagram for the furnace printed in this

document or on the inside of the fur-

nace blower door.

For troubleshooting purposes, follow

the wiring diagram and troubleshooting

flowchart supplied in this manual and

on the inside of the furnace blower

door. Additionally, the pin designations

for the connector are specified below:

Pin 1 to stepper modulating gas valve

connector Pin 1 (TH)

Pin 2 to stepper modulating gas valve

connector Pin 2 (RX)

Pin 3 to stepper modulating gas valve

connector Pin 3 (TX)

Pin 4 to stepper modulating gas valve

connector Pin 4 (COMMON)

Pin 5 to stepper modulating gas valve

connector Pin 5 (MVTH)

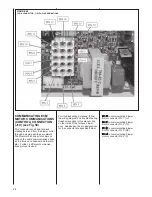

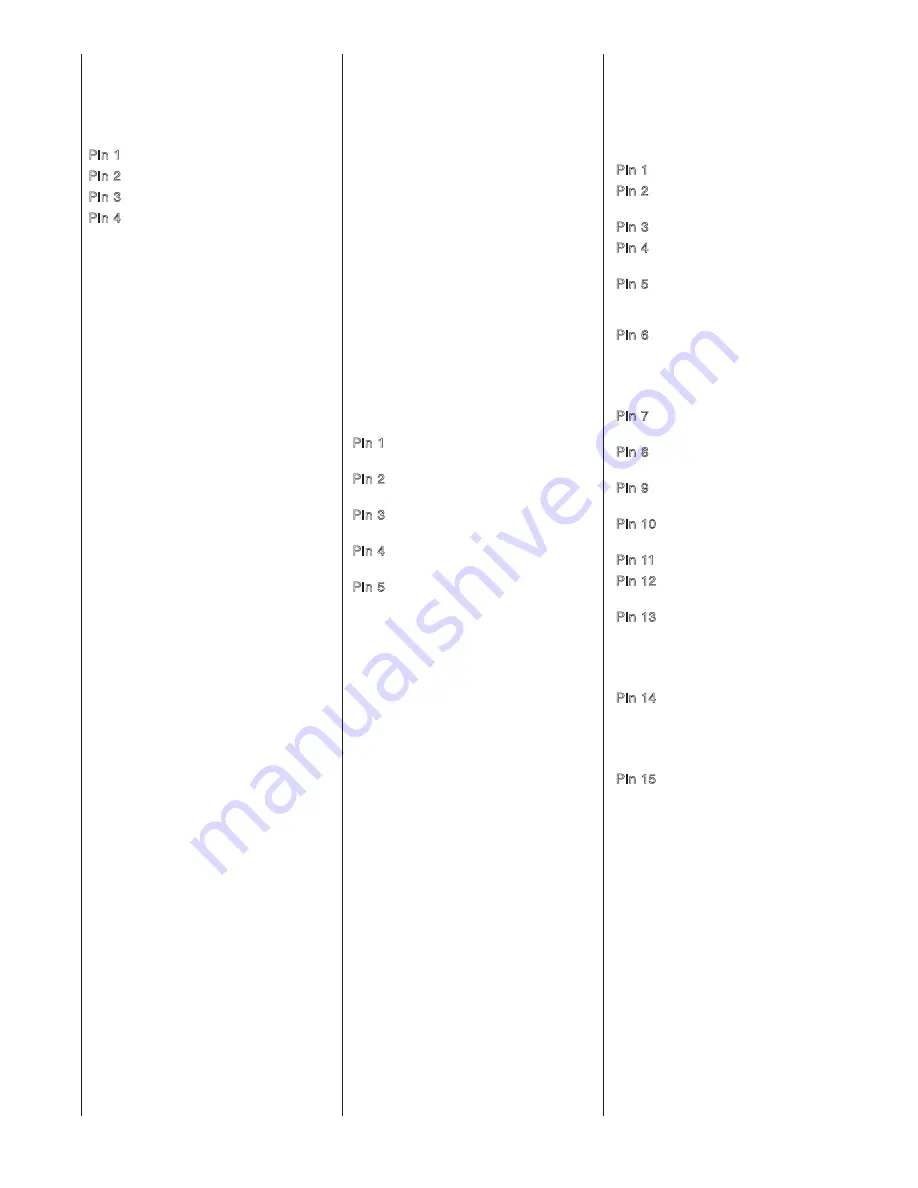

15-PIN MATE-N-LOK CON-

NECTOR (J1) (see Fig 58)

The 15-pin Mate-n-Lok style connector

provides connections for a variety of

inputs and outputs to the furnace con-

trol. For modulating furnaces with a

solenoid-controlled modulating gas

valve (HG or HH Fuel Codes) the 15-

pin connector provides power and con-

trol signals to the gas valve. Also, the

flame sense, pressure switches sense

and limits sense (Main Limit, MRLC

and HALC) are connected to the I.F.C.

through this connector. Reference the

wiring diagram for the furnace printed

in this document or on the inside of the

furnace blower door for pin assign-

ments for troubleshooting.

For troubleshooting purposes, follow

the wiring diagram and troubleshoot-

ing flowchart supplied in this manual

and on the inside of the furnace

blower door. Additionally, the pin

designations for the connector are

specified below:

Pin 1 to Flame Sense rod.

Pin 2 to Overtemp Limit (MRLC)

Sense

Pin 3 to Main Limit (LC) Sense

Pin 4 to 24 VAC to Limit Sense

Circuits

Pin 5

24 VAC out to Auxiliary Limit

(HALC- Heat Assisted Limit

Control)

Pin 6 Solenoid-controlled modulat-

ing gas valve main solenoid

24VAC (not used on fur-

naces with stepper (servo)

modulating gas valve).

Pin 7 is not used on the production

control.

Pin 8 to Low Pressure Switch

sense.

Pin 9 to High Pressure Switch

sense.

Pin 10 to Low and High Pressure

Switch 24VAC

Pin 11

to Aux Input sense

Pin 12 to Ground on furnace cabi-

net

Pin 13 Solenoid-controlled modulat-

ing gas valve control circuit

(not used on furnaces with

stepper (servo) modulating

gas valve).

Pin 14 Solenoid-controlled modulat-

ing gas valve control circuit

(not used on furnaces with

stepper (servo) modulating

gas valve).

Pin 15 Solenoid-controlled modulat-

ing gas valve main solenoid

24VAC common (not used

on furnaces with stepper

(servo) modulating gas

valve).

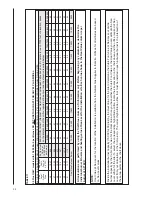

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...