68

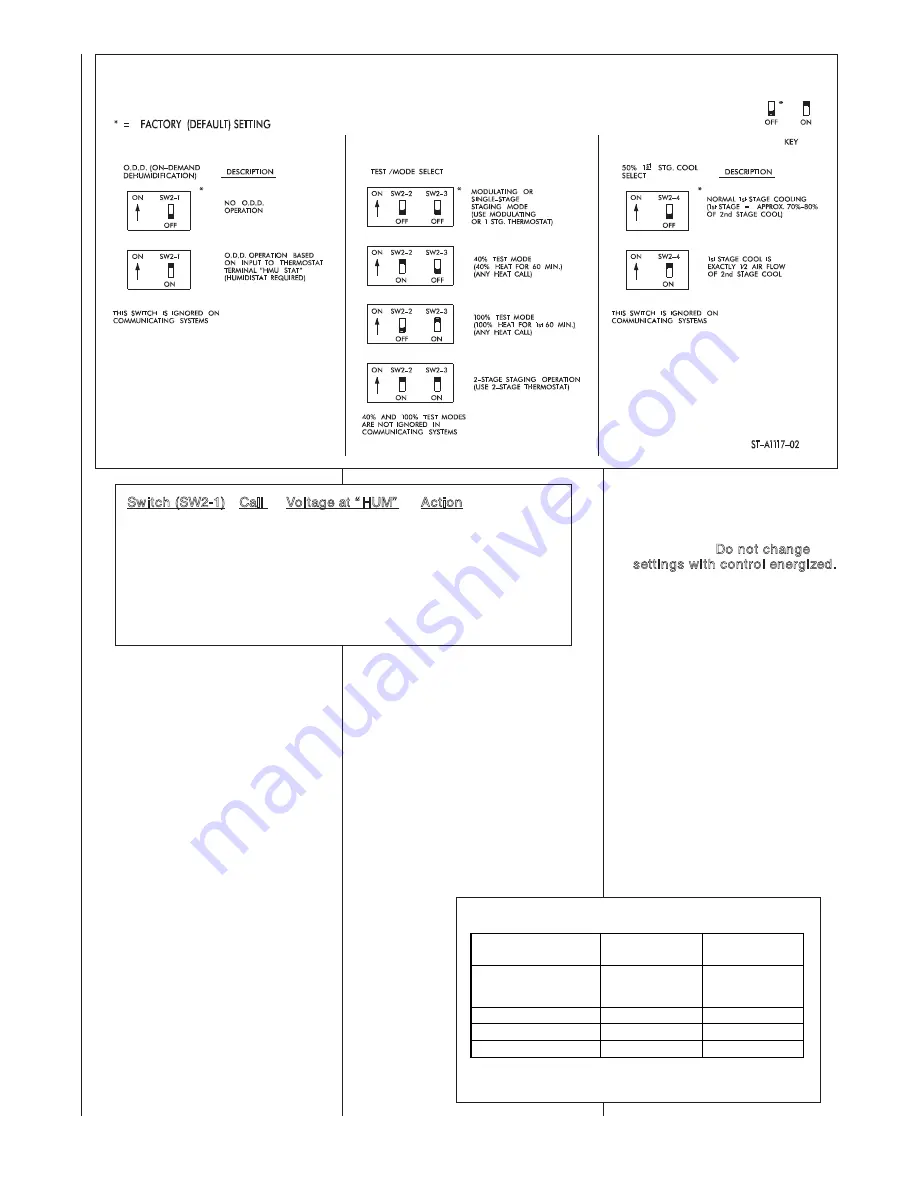

SW2-2 and SW2-3 -

FURNACE TEST and OPERATING

MODES

FURNACE TEST SWITCHES

The Test Switches (SW2) will place the

IFC into a test mode, operating the fur-

nace at continuous input rates of either

100% of full rate (maximum fire) or

40% of full rate (minimum fire). This is

accomplished by setting the Test

Switches as indicated in Table 15

below.

To enter the Furnace Test Mode,

proceed as follows:

1 Switch the 115 volt power to the

furnace OFF. Do not change

settings with control energi

z

ed.

2 Remove furnace blower door.

3 Position Test Switches SW2-2

and SW2-3 for the desired test

mode.

4 Replace furnace blower door.

5. Switch the 115 volt power to the

furnace ON.

6. Set the thermostat mode to

HEAT, adjust the setpoint at least

4°F above room temperature to

demand a call for heating.

When the furnace is powered with

the test switches in a position other

than modulating/single-stage or in 2-

stage mode, the first call for heat

within the first hour after power-up

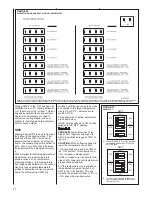

Switch (SW2-1) Call

Voltage at “ HUM”

Action

ON

COOL

24

Normal Cool (c or C)

ON

COOL

0

Dehum Cool (cd or Cd)

ON

Heat

24

Hum Contacts Closed.

ON

Heat

0

Hum Contacts Open.

OFF

COOL

24

Normal Cool (c or C)

OFF

COOL

0

Normal Cool (c or C)

OFF

Heat

24

Hum Contacts Closed.

OFF

Heat

0

Hum Contacts Open.

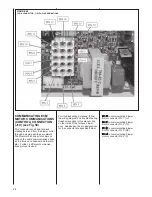

SW2

SW2-1

= ODD “ON” or “OFF” select.

This switch will ignore the input from the

24 volt terminal labeled “HUM STAT”

during cooling when in the “OFF” posi-

tion. However, the “HUM STAT” input is

always read in the heating mode to turn

on and off the humidifier relay.

When in the “ON” position, the dehumid-

ification feature will become active and it

will be necessary to install a humidistat

to the “HUM STAT” terminal as dis-

cussed and shown in wiring diagrams in

the section of this manual titled

“

HUMIDIFICATION AND DEHUMIDIFI-

CATION” of this document. Failure to

install a humidistat to the “HUM STAT”

terminal with dipswitch SW2-1 in the

“ON” position will cause the cooling

speed airflow to be reduced to the

dehumidification speed..

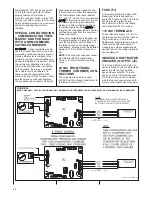

FIGURE 68

DIPSWITCH BANK SW2 TEST MODE SELECT

TABLE 15

SW2-2 AND SW2-3 MODE SELECTION SETTINGS

of full rate (minimum fire and 2-stage operation). This is accomplished by setting

the Test Switches as indicated in Table XX below.

Table XX

- SW2-2 and SW2-3 MODE SELECTION SETTINGS

Mode

Switch SW2-2

Position

Switch SW2-3

Position

Modulating/ Single-

Stage

OFF

OFF

Test 40%

ON

OFF

Test 100%

OFF

ON

Two-Stage

ON

ON

Note: the “

Test 40%

” and “

Test 100%

” settings will time out and become invalid

one hour after power reset.

To enter the Furnace Test Mode, proceed as follows:

1

Switch the 115 volt power to the furnace OFF.

Do not change settings

with control energized.

2

Position Test Switches SW2-2 and SW2-3 for the desired test mode.

3

Switch the 115 volt power to the furnace ON.

4

Set the thermostat mode to HEAT, adjust the setpoint at least 4°F above

room temperature to demand a call for heating.

When the furnace is powered with the test switches in a position other than

modulating/single-stage or in 2-stage mode, the first call for heat within the first

hour after power-up will instruct the furnace to perform as follows:

1

Normal ignition sequence

2

A calibration cycle will be performed unless the Test Switches are set for

Test 40%. The LED status indicator will flash “H” or “h” during the cali-

bration cycle (see Table XX).

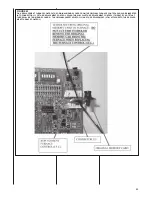

NOTE:

The supply air sensor (field installed) is required for the furnace

calibration cycle. If the air sensor is faulty, or not properly connected, the furnace

will not attempt a calibration cycle and will operate on factory default parameters

pre-programmed into the microprocessor.

After calibration, the furnace will then adjust to the desired Test capacity. This

allows time for the technician to check steady-state operation and evaluate

furnace performance.

The furnace will operate at the fixed Test capacity until one of the following

conditions:

A.

The thermostat is satisfied and the call for heat is removed.

B.

The furnace has been in test mode continuously for sixty minutes, at

which time the controller will exit the test mode and proceed to normal

heating operation as configured. Test mode can not be activated again

unless power to the furnace is cycled off and back on. This is true even if

Note: The

“Test 40%”

and

“Test 100%”

settings will time out

and become invalid one hour after power reset.

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...