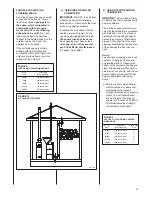

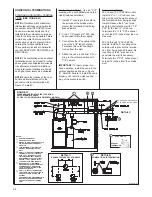

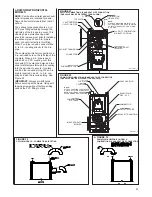

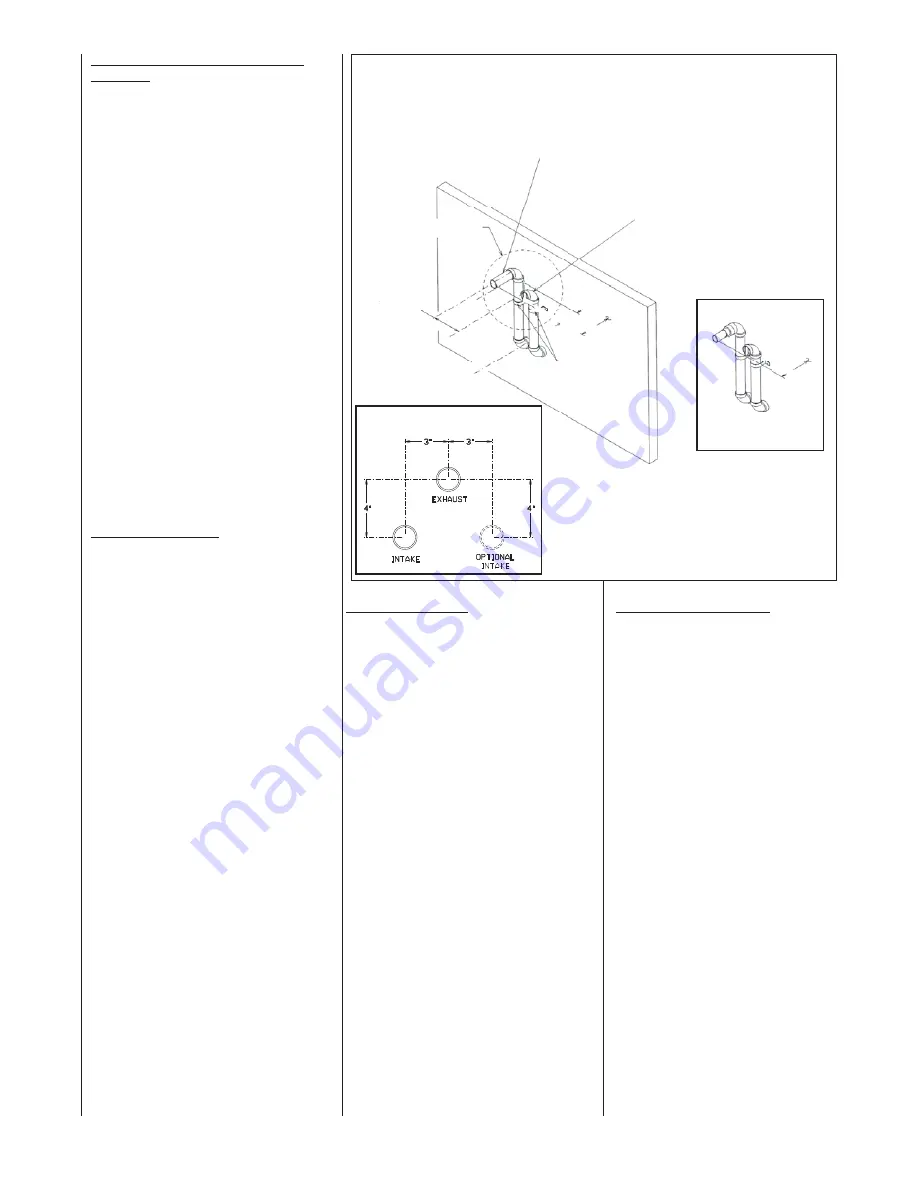

FIGURE 22

ALTERNATE HORIZONTAL DIRECT VENT TERMINATION

SEE DETAIL A

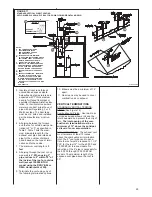

PIPE

SUPPORT

STRAP

3" MAX.

NOTE: 3-1/2"

MAX. WHEN

D04 KIT IS

USED.

EXHAUST VENT FOR

MODELS WITH INPUT OF

60,000 AND 75,000 BTU

EXHAUST VENT

2

1

/

2

" PVC FOR MODELS WITH 120,000 BTUH INPUT

(KIT NO. RXGY-D04A)

2" PVC FOR MODELS WITH INPUTS OF 90,000 THRU 120,000

BTUH. REDUCE TO 1

1

/

2

" FOR MODELS WITH INPUTS OF 60,000

AND 75,000 BTUH. ELBOWS AND RISERS ARE 2" PVC.

INTAKE VENT

2

1

/

2

" PVC FOR MODELS WITH

120,000 BTUH INPUT.

2" PVC ELBOWS AND RISER

MODELS WITH INPUTS OF 75,000

THRU 120,000 BTUH.

USE KIT NO. RXGY-D02 OR D02A WHEN 2"

PIPE IS USED BETWEEN FURNACE AND

OUTSIDE WALL. USE KIT NO. RXGY-D03

OR D03A WHEN 3" PIPE IS USED.

I

339

12"

FR

OM

WALL

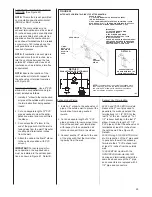

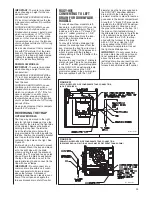

ALTERNATE HORIZONTAL TERMI-

NATIONS (See Figure 22)

NOTE:

This method is not permitted

on modulation downflow/horizontal

(RGGE or RGJF) models.

NOTE:

The combustion air and

exhaust terminations must be at least

12 inches above grade or anticipated

snow levels. Alternate horizontal ter-

minations allow the combustion air

and exhaust terminations to be raised

a maximum of 60 inches above the

wall penetrations to maintain the

required clearance.

NOTE:

If combustion air vent pipe is

extended more than 24 inch

es, insu-

late the vent pipe between the two

outside 90° elbows with closed cell

insulation such as rubatex, armaflex

or equivalent.

NOTE:

Ensure the location of the

combustion air inlet with respect to

the exhaust vent terminal complies

with Figure 22.

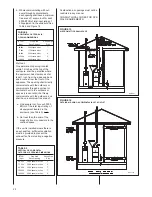

Combustion Air Piping: Use a 2" PVC

elbow with a wind deflector vane (pro-

vided) installed as follows:

1. Install a 2" elbow to the combustion

air pipe at the outside wall to prevent

the termination from being pushed

inward.

2. Cut an adequate length of 2" PVC

pipe as needed to clear the antici-

pated snow level and connect this to

the elbow.

3. Connect another 2" elbow to the

end of the pipe such that the inlet is

facing away from the wall. This outer

coupling must terminate 4 inches

from the wall.

4. Attach the vane in the final 2" elbow

in the vertical position with PVC

solvent.

IMPORTANT:

To insure proper fur-

nace operation, the supplied vane

must be installed in the vertical posi-

tion as shown in Figure 21, Detail B.

Exhaust Vent Piping

:

1. Install a 2" elbow to the exhaust vent

pipe at the outside wall to prevent the

termination from being pushed

inward.

2. Cut an adequate length of 2" PVC

pipe as needed to insure proper loca-

tion of the exhaust vent termination

with respect to the combustion air

inlet and connect this to the elbow.

3. Connect another 2" elbow to the end

of the pipe such that the inlet is fac-

ing away from the wall.

Exhaust Vent Termination

:

60,000 and 75,000 BTUH models

:

Reduce the 2" vent pipe used to

penetrate the wall and extend the

terminations to 1 1/2" PVC for the

last 12" of the run. Install a 2" to 1

1/2" reducer bushing in the last 2"

elbow. Connect a length of 1 1/2"

PVC pipe such that the exhaust vent

terminates at least 12 inches from

the outside wall. See Figure 22,

Detail A.

90,000 through 120,000 BTUH mod-

els

: No reduction of the 2" pipe used

to penetrate the wall is necessary.

Terminate the 2" PVC exhaust vent

at least 12 inches from the outside

wall.

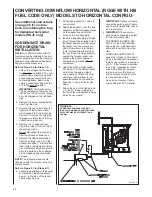

120,000 BTUH model with the

RXGY-D04A Horizontal Vent Kit:

Venting and terminations install the

same as above except the 2" pipe

and connectors are replaced with 2

1/2" pipe and connectors.

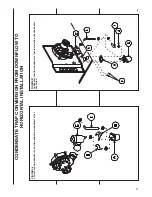

DETAIL A

DETAIL C

EXHAUST/INTAKE RELATIONSHIP

NOTE:

If combustion air vent pipe is extended more

than 24 inches, insulate the vent pipes between the

two outside 90° elbows with closed cell insulation

such as rubatex, armaflex, or equivalent.

29

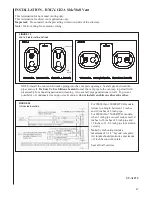

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...