69

FURNACE OPERATION

USING NON-COMMUNICAT-

ING MODULATING, SIN-

GLE-STAGE, AND TWO-

STAGE THERMOSTATS

(CONSULT THE SECTION

OF THIS DOCUMENT

TITLED NON-COMMUNI-

CATING THERMOSTATS

FOR WIRING DIAGRAMS)

The modulating furnace is capable of

operating with a single-stage or a two-

stage thermostat as well as the modu-

lating thermostat or fully communicating

thermostat specified for use with the

furnace. Fully communicating thermo-

stat functions and operations are

explained in detail in the sections of

this manual titled

COMMUNICATING

SYSTEMS

and

THERMOSTATS

(under

the sub-section titled

COMMUNICAT-

ING THERMOSTATS)

.

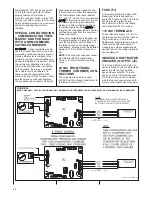

Based on the dipswitch settings of

SW2-2 and SW2-3, the furnace will

operate with either single-stage or two-

stage thermostats as a modulating sys-

tem using an algorithm that utilizes

three distinct firing rates; 40%, 65%

and 100% of the furnace heating

capacity (See below for operation of

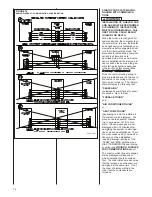

each). See Figure 68 to determine

which dipswitch settings are necessary

for operation with a modulating, single-

stage or two-stage thermostat.

See the section of this document titled

THERMOSTATS

(under the sub-sec-

tion titled

NON-COMMUNICATING

THERMOSTATS)

for information on

how to wire the thermostats for each of

the configurations below.

In non-communicating systems, the

heating cycle is always initiated by a 24

volt signal on W1. When the controller

senses 24 volts on W1, the following

sequence occurs:

MODULATING FUNCTION:

(Modulating function with a non-com-

municating thermostat only applies

when both switches SW2-2 and SW2-3

are in the “ OFF” position and a non-

communicating modulating thermostat

(specified for use with the furnace) is

installed as shown in Figure 88.)

After the warm-up period, the furnace

will respond to the thermostat demand

by adjusting the gas valve pressure

and blower speed between 40% and

100% of maximum heating capacity.

will instruct the furnace to perform as

follows:

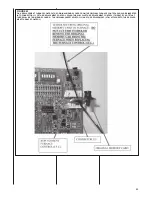

1 Normal ignition sequence

2 A calibration cycle will be performed

unless the Test Switches are set for

Test 40%. The LED status indicator

will flash “H” or “h” during the cali-

bration cycle.

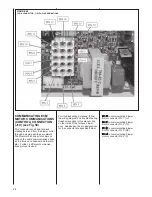

NOTE: The supply air sensor (field

installed) is required for the furnace cali-

bration cycle. If the air sensor is faulty,

or not properly connected, the furnace

will not attempt a calibration cycle and

will operate on factory default parame-

ters pre-programmed into the micro-

processor.

After calibration, the furnace will then

adjust to the desired Test capacity. This

allows time for the technician to check

steady-state operation and evaluate fur-

nace performance.

The furnace will operate at the fixed

Test capacity until one of the following

conditions:

A. The thermostat is satisfied and the

call for heat is removed.

B. The furnace has been in test mode

continuously for sixty minute

s, at

which time the furnace control (IFC)

will exit the test mode and proceed to

normal heating operation as config-

ured. Test mode can not be activat-

ed again unless line voltage power to

the furnace is cycled off and back on.

This is true even if the dipswitches

remain configured to the test settings.

To set the furnace for normal oper-

ation:

1 Set the thermostat mode to OFF.

Always allow furnace to complete the

cool down cycle.

2 Switch the 115 volt power to the fur-

nace OFF. Do not change settings

with control energi

z

ed.

3 Remove furnace blower door.

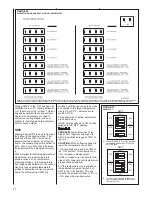

4 Position dipswitches SW2-2 and

SW2-3 for modulating/single-stage

mode or 2-stage mode.

5 Replace furnace blower door.

6. Switch the 115 volt power to the fur-

nace ON.

7. Set the thermostat as desired.

TWO-STAGE FUNCTION:

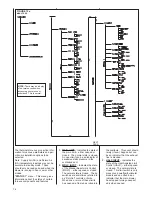

(Two-stage function only applies

when both switches SW2-2 and

SW2-3 are in the “ ON” position

and a two-stage thermostat is

installed as shown in Figure 90.)

After the blower on-delay period, the

furnace will respond to the thermo-

stat demand by adjusting the gas

valve pressure and blower heating

speeds to the “W” signal values.

“W1” only = 40% gas valve pressure

and blower heating speed. “W2” =

65% gas valve pressure and blower

heating speed for the first five min-

utes and 100% thereafter. Also, if

the call for heat ends, the furnace

terminates at the present rate.

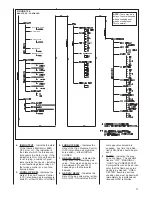

SINGLE-STAGE FUNCTION (“W”

signal only) :

(Single-stage function only applies

when both switches SW2-2 and

SW2-3 are in the “ OFF” position

and a single-stage thermostat is

installed as shown in Figure 89.)

After the blower on-delay period, the

furnace will respond to the thermo-

stat demand by altering the gas

valve pressure and blower speed as

follows:

Phase 1: 0 to 5 minutes = 40% of

furnace capacity (gas valve output

and blower speed)

Phase 2: 5 to 12 minutes = 65% of

furnace capacity (gas valve output

and blower speed)

Phase 3: After 12 minutes = 100%

of furnace capacity (gas valve out-

put and blower speed)

NOTE: If the call for heat ends dur-

ing any phase, the furnace will ter-

minate immediately at the firing rate

of that phase.

SW2-4 - For most cooling operation,

leave dip switch SW2-4 in the “OFF”

position. This will enable the furnace

operation with most two-stage, non-

communicating cooling equipment.

Actual SEER values will vary and

depend on the equipment combina-

tion. Consult the specifications

sheets and installation instructions

of the cooling equipment purchased

for a listing of the SEER ratings for a

specific combination.

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...