112

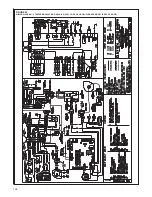

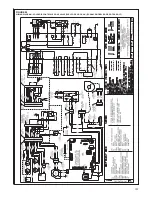

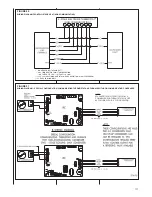

FIGURE 93

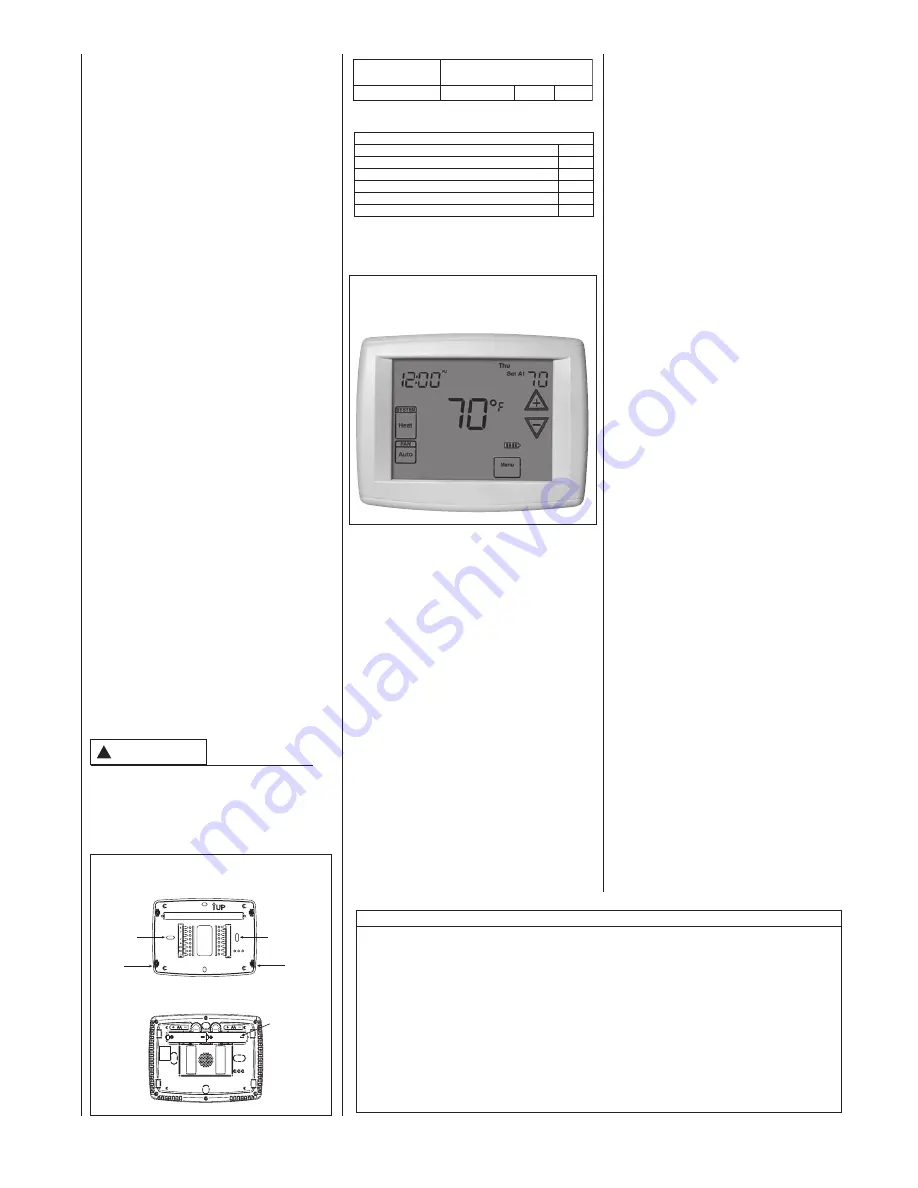

(-)HC-TST412MDMS

MODULATING TOUCHSCREEN THERMOSTAT

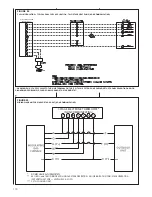

FURNACE OPERATION WITH A TWO-

STAGE THERMOSTAT

To set the furnace for operation with

two-stage non-communicating ther-

mostats, set switches 2 & 3 of SW2 to

the “ON” position (See Figure 66). Note

that these switches should be in the

“OFF” position from the factory. With

both switches in the “ON” position, the

furnace can still recognize a “V” sig

nal

present and will still operate with a

modulating thermostat. However, with

both switches of SW2 in the “ON” posi-

tion, the furnace is set to operate with a

two-stage thermostat as well.

With a two-stage non-communicating

thermostat (installed as shown in Figure

92) and switch settings configured as

described above, during a call for heat,

the furnace will operate as follows:

First Stage

(“W”=ON and “W2”=OFF)

40% of furnace capacity always

Second Stage

(“W”=ON and “W2”=ON)

Phase 1

: 0 to 5 minutes = 65% of fur-

nace capacity

Phase 2

: After 5 minutes = 100% of

furnace capacity

NOTE:

If the call for heat ends during

any phase and/or stage, the furnace

will terminate immediately at the firing

rate of that phase and/or stage.

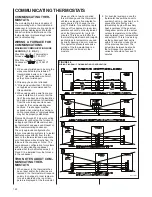

APPLICATIONS

MODULATING TOUCH-

SCREEN NON-COMMUNI-

CATING THERMOSTAT

24 VOLT CONTROL

INSTALLATION

THERMOSTAT INSTALLATION AND

ALL COMPONENTS OF THE CON-

TROL SYSTEM SHALL CONFORM TO

CLASS II CIRCUITS PER THE NEC

CODE.

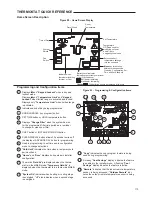

Description

Heat Pump (with Aux. or Emergency Heat), 2 Stage

Yes

Systems with up to 3 Stages Heat, 2 Stages Cool

Yes

Heat Only Systems

Yes

Wired Remote Temperature Sensor (Indoor/Outdoor)

Yes

Dual Fuel Feature (Heat Pump Mode)

Yes

Yes

THERMOSTAT APPLICATION GUIDE

Model

Programming Choices

(-)HC-TST401MDMS

Non-Programmable 5/1/1 Day

7 Day

Modulating PWM output, gas furnace

Description

Heat Pump (with Aux. or Emergency Heat),

2 Stage

Yes

Systems with up to 3 Stages Heat, 2 Stages Cool

Yes

Heat Only Systems

Yes

Wired Remote Temperature Sensor (Indoor/Outdoor)

Yes

Dual Fuel Feature (Heat Pump Mode)

Yes

Yes

THERMOSTAT APPLICATION GUIDE

Model

Programming Choices

(-)HC-TST412MDMS

Non-Programmable 5/1/1 Day

7 Day

Modulating PWM output, gas furnace

thermostat will cause damage to

the unit. Rear view of thermostat

2. Place base over hole in wall and

mark mounting hole locations on

wall using base as a template.

3. Move base out of the way. Drill

mounting holes. If you are using

existing mounting holes and the

holes drilled are too large and do

not allow you to tighten base

snugly, use plastic screw anchors

to secure the base.

4. Fasten base snugly to wall using

mounting holes shown in Figure

92 and two mounting screws.

Leveling is for appearance only

and will not affect thermostat oper-

ation.

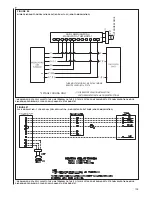

5. Connect wires to terminal block on

base using appropriate wiring

schematic (see Figures 86, 87 &

88).

6. Push excess wire into wall and

plug hole with a fire resistant

material (such as fiberglass insula-

tion) to prevent drafts from affect-

ing thermostat operation.

7. Carefully line the thermostat up

with the base and snap into place.

BATTERY LOCATION

2 “AA” alkaline batteries are includ-

ed in the thermostat at the factory

with a battery tag to prevent power

drainage. Remove the battery tag to

engage the batteries. To replace

batteries, set system to

OFF

,

remove thermostat from wall and

install the batteries in the rear along

the top of the thermostat (see Figure

92).

WIRING CONNECTIONS

Refer to equipment manufacturers’

instructions for specific system wiring

information. After wiring, see CON-

FIGURATION section for proper ther-

mostat configuration. For wiring dia-

grams, see Figures 86, 87 & 88.

Wiring diagrams shown are for typi-

cal systes and describe the thermo-

stat terminal functions.

!

WARNING

For complete product specifications, see

the Installation Instructions supplied with

thermostat.

2

2 "AA" Batteries

Terminal Designation

Description

B . . . . . . . . . . . . . . . . . . C

hangeover valve for heat pump energized c

onstantly in heating

O . . . . . . . . . . . . . . . . . . Changeover valve for heat pu

mp energized c

onstantly in cooling

Y2 . . . . . . . . . . . . . . . . . . 2nd Stage Compressor

Y . . . . . . . . . . . . . . . . . . Compressor Relay

G . . . . . . . . . . . . . . . . . . Fan Relay

RC . . . . . . . . . . . . . . . . . . Power for Cooling

RH . . . . . . . . . . . . . . . . . . Power for Heating

C . . . . . . . . . . . . . . . . . . Common wire from secondary side of cooling

V . . . . . . . . . . . . . . . . . . PWM Output

W/E . . . . . . . . . . . . . . . . . Heat Relay/Emergency Heat Relay (Stage 1)

W2 . . . . . . . . . . . . . . . . . . 2nd Stage Heat (3rd Stage Heat in HP2)

- . . . . . . . . . . . . . . . . . . . Common (DC) for wired remote temperature sensor

S . . . . . . . . . . . . . . . . . . Frequency signal from remote temperature sensor

+ . . . . . . . . . . . . . . . . . . Power (D

C) to remote temperature sensor

TERMINAL DESIGNATION DESCRIPTIONS

Mounting

Hole

Mounting

Hole

Place Level

across

Mounting Tabs

(for appearance only)

Place Level

across

Mounting Tabs

(for appearance only)

+

S

-

W/E

V

Y2

W2

Rear view of thermostat

FIGURE 92

(-)HC-TST412MDMS BASE

2

2 "AA" Batteries

Terminal Designation

Description

B . . . . . . . . . . . . . . . . . . C

hangeover valve for heat pump energized c

onstantly in heating

O . . . . . . . . . . . . . . . . . . Changeover valve for heat pu

mp energized c

onstantly in cooling

Y2 . . . . . . . . . . . . . . . . . . 2nd Stage Compressor

Y . . . . . . . . . . . . . . . . . . Compressor Relay

G . . . . . . . . . . . . . . . . . . Fan Relay

RC . . . . . . . . . . . . . . . . . . Power for Cooling

RH . . . . . . . . . . . . . . . . . . Power for Heating

C . . . . . . . . . . . . . . . . . . Common wire from secondary side of cooling

V . . . . . . . . . . . . . . . . . . PWM Output

W/E . . . . . . . . . . . . . . . . . Heat Relay/Emergency Heat Relay (Stage 1)

W2 . . . . . . . . . . . . . . . . . . 2nd Stage Heat (3rd Stage Heat in HP2)

- . . . . . . . . . . . . . . . . . . . Common (DC) for wired remote temperature sensor

S . . . . . . . . . . . . . . . . . . Frequency signal from remote temperature sensor

+ . . . . . . . . . . . . . . . . . . Power (D

C) to remote temperature sensor

TERMINAL DESIGNATION DESCRIPTIONS

Mounting

Hole

Mounting

Hole

Place Level

across

Mounting Tabs

(for appearance only)

Place Level

across

Mounting Tabs

(for appearance only)

+

S

-

W/E

V

Y2

W2

Rear view of thermostat

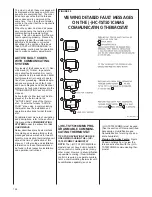

REMOVE OLD THERMOSTAT

A standard heat/cool thermostat con-

sists of three basic parts:

1. The cover, which may be either a

snap-on or hinge type.

2. The base, which is removed by loos-

ening all captive screws.

3. The switching subbase, which is

removed by unscrewing the mounting

screws that hold it on the wall or

adapter plate.

Before removing

wires from old thermostat, label

each wire with the terminal desig-

nation from which it was attached.

Disconnect the wires from the old

thermostat one at a time.

Do not let

wires fall back into the wall.

INSTALLING NEW THERMOSTAT

1. Pull the thermostat body off the ther-

mostat base. Forcing or prying on the

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...