54

Evaporator coil must be the same width as the furnace OR one size larger in width than the gas furnace.

(See condenser spec. sheet, I&O and other literature for evaporator selection)

Evaporator coil must be the same width as the furnace OR one size larger in width than the gas furnace.

(See condenser spec. sheet, I&O and other literature for evaporator selection)

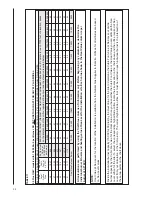

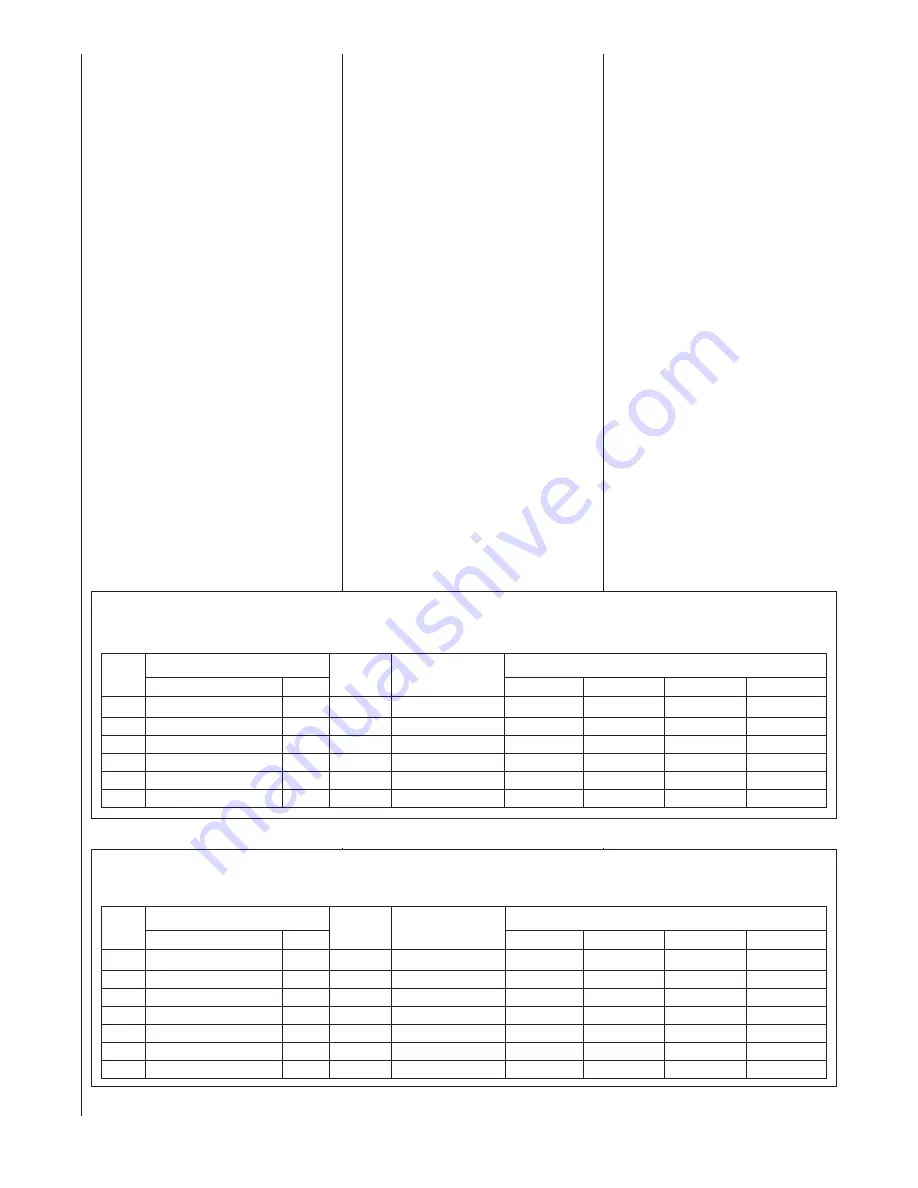

TABLE 14

AIRFLOW AND CONDENSER SELECTION – PREMIUM (NON-COMMUNICATING) COOLING SYSTEMS (2 STAGE COOL)

(NOTE: SWITCH SW2-4 OF THE IFC MUST BE IN THE “OFF” POSITION FOR OPTIMUM PERFORMANCE)

TABLE 13

AIRFLOW AND CONDENSER SELECTION – PREMIUM (NON-COMMUNICATING) COOLING SYSTEMS (1 STAGE COOL ONLY)

(NOTE: SWITCH SW2-4 OF THE IFC MUST BE IN THE “OFF” POSITION FOR OPTIMUM PERFORMANCE)

ZONING SYSTEMS

The manufacturer does not currently

provide or support zoning with modulat-

ing furnace. However, zoning systems

can be installed with the system as long

as the zoning equipment manufacturers

specifications and installation instruc-

tions are met and followed.

The preferred zoning method is to use

a “bypass” system which is properly

installed for maximum efficiency. In

these systems, excess

air is routed

back through the system to be used

again – this is opposed to a “dump”

system in which excess air is routed to

a zone where it is expected that the

extra heat or cooling would be least

noticed.

If installed as a “bypass” system, the

installation must have an optional

freeze stat installed to prevent the coil

from icing with excess bypass cooling.

Also, if the zoning equipment manufac-

turer provides a limit switch (usually

provided by the zoning manufacturer),

this limit must be installed in the system

to prevent the furnace from overheat-

ing.

FURNACE INSTALLATION

WITH NON-COMMUNICAT-

ING HIGH-EFFICIENCY

PREMIUM COOLING OR

HEAT PUMP SYSTEMS

Furnace installation with Rheem/Ruud

-ASL or -ARL outdoor condensing units

can provide high efficiency (up to 16

SEER) cooling operation when com-

bined with proper evaporator coil. For

listed cooling equipment combinations,

see the -ARA or -ARL specification

sheets and Tables 13 and 14 of this

document. Using Tables 13 and 14 and

literature provided with the cooling

equipment, the installer needs to make

sure that the proper evaporator coil,

condensing coil and airflow is config-

ured to achieve rated efficiency.

In accordance with Rheem/Ruud cool-

ing equipment installation instructions,

do not install an evaporator coil or coil

casing to the furnace which is smaller

in width than the furnace cabinet.

TONS

FURNACE

MODEL

WIDTH

APPROX.

AIRFLOW

(CFM)

SW-1,#1

SW-1,#2

SW-1,#3

SW-1,#4

CONDENSING

UNIT

MOD. FURNACE IFC DIP-SWITCH SETTINGS

2

-GFE/GGE-06 & -07

17.5"

800

-ARA-24

OFF

ON

OFF

OFF

2-1/2

-GFE/GGE-06 & -07*

17.5"

1000

-ARA-30

ON

OFF

OFF

OFF

3

-GFE/GGE-09 & -10*

21"

1200

-ARA-36

ON

ON

OFF

OFF

3-1/2

-GFE/GGE-09 & -10*

21"

1400

-ARA-42

ON

ON

OFF

OFF

3

-GFE/GGE-12

24.5"

1200

-ARA-36

ON

ON

OFF

OFF

3-1/2

-GFE/GGE-12

24.5"

1400

-ARA-42

ON

ON

OFF

OFF

TONS

FURNACE

MODEL

WIDTH

APPROX.

AIRFLOW

(CFM)

SW-1,#1

SW-1,#2

SW-1,#3

SW-1,#4

CONDENSING

UNIT

MOD. FURNACE IFC DIP-SWITCH SETTINGS

2

-GFE/GGE-06 & -07

17.5"

800

-ARL/ASL-24

OFF

ON

OFF

OFF

3

-GFE/GGE-06 & -07

17.5"

1200

-ARL/ASL-36

OFF

OFF

OFF

OFF

3

-GFE/GGE-09 & -10

21"

1200

-ARL/ASL-36

ON

ON

OFF

OFF

3

-GFE/GGE-12

24.5"

1200

-ARL/ASL-36

ON

ON

OFF

OFF

4

-GFE/GGE-09 & -10

21"

1600

-ARL/ASL-48

ON

OFF

OFF

OFF

4

-GFE/GGE-12

24.5"

1600

-ARL/ASL-48

ON

OFF

OFF

OFF

5

-GFE/GGE-12

24.5"

1800

-ARL/ASL-60

OFF

OFF

OFF

OFF

UP TO 16 SEER COOLING

OPERATION

Check the revision number of the

integrated furnace control (IFC) to

determine how best to configure

your furnace for high SEER opera-

tion.

To achieve high SEER operation,

turn dip switch #4 of bank SW2 to

the “off” position (factory setting).

This will enable the furnace opera-

tion for 16 SEER. Actual SEER val-

ues will vary and depend on the

equipment combination. Consult the

specifications sheets and installation

instructions of the cooling equipment

purchased for a listing of the SEER

ratings for a specific combination.

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...