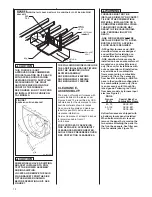

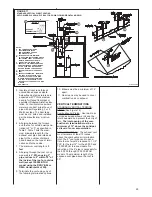

3. Apply a thin coat of cement

evenly in the socket. Quickly

apply a heavy coat of cement to

the pipe end and insert pipe into

fitting with a slight twisting move-

ment until it bottoms out.

NOTE:

Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling. Cure time varies

according to fit, temperature and

humidity.

NOTE:

Stir the solvent cement

frequently while using. Use a

natural bristle, one inch wide

brush or the applicator supplied

with the can.

IMPORTANT:

For Proper Installation

DO NOT use solvent cement that has

become curdled, lumpy or thickened.

DO NOT thin. Observe shelf precau-

tions printed on containers. For appli-

cation below 32°F, use only low-tem-

perature-type solvent cement.

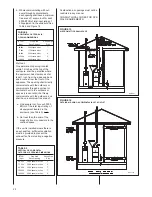

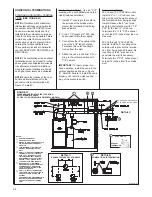

For correct installation of the vent

pipe, follow the instructions provided

by the manufacturers of the pipe,

primer and solvent.

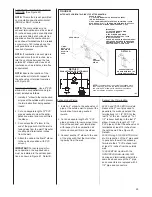

JOINING PIPE AND

FITTINGS

PVC SOLVENT CEMENTS AND

PRIMERS ARE HIGHLY FLAM-

MABLE. PROVIDE ADEQUATE

VENTILATION AND DO NOT

ASSEMBLE COMPONENTS

NEAR HEAT SOURCE OR AN

OPEN FLAME. DO NOT

SMOKE. AVOID SKIN OR EYE

CONTACT. OBSERVE ALL CAU-

TIONS AND WARNINGS PRINT-

ED ON MATERIAL CONTAIN-

ERS. FAILURE TO FOLLOW

THESE GUIDELINES MAY

RESULT IN FIRE, EXPLOSION

OR ASPHYXIATION CAUSING

PERSONAL INJURY OR DEATH.

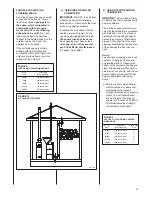

All pipe, fittings, solvent cement,

primers and procedures must conform

to American National Standard

Institute and American Society for

Testing and Materials (ANSI/ASTM)

standards as shown below:

IMPORTANT:

The plastic combustion

air and venting components are MADE

of PVC. If using ABS piping, ensure that

the solvent cement is compatible for

joining PVC to ABS components or use

a mechanical connection that can with-

stand the vent temperatures and is cor-

rosion resistant.

CEMENTING JOINTS

Properly seal all joints in the PVC vent

using the following materials and proce-

dures:

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT:

After cutting pipe, remove

all ragged edges and burrs. This is

important to prevent increase in pres-

sure drop throughout the system.

1. Cut pipe end square. Chamfer edge

of pipe. Clean fitting socket and

pipe joint area of all dirt, grease and

moisture.

2. After checking pipe and socket for

proper fit, wipe socket and pipe with

cleaner-primer. Apply

a liberal coat of primer to inside sur-

face of socket and outside of pipe.

READ INSTRUCTIONS INCLUDED

WITH THE PRIMER FOR PROPER

INSTALLATION.

!

WARNING

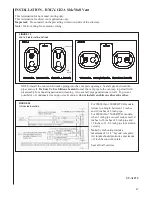

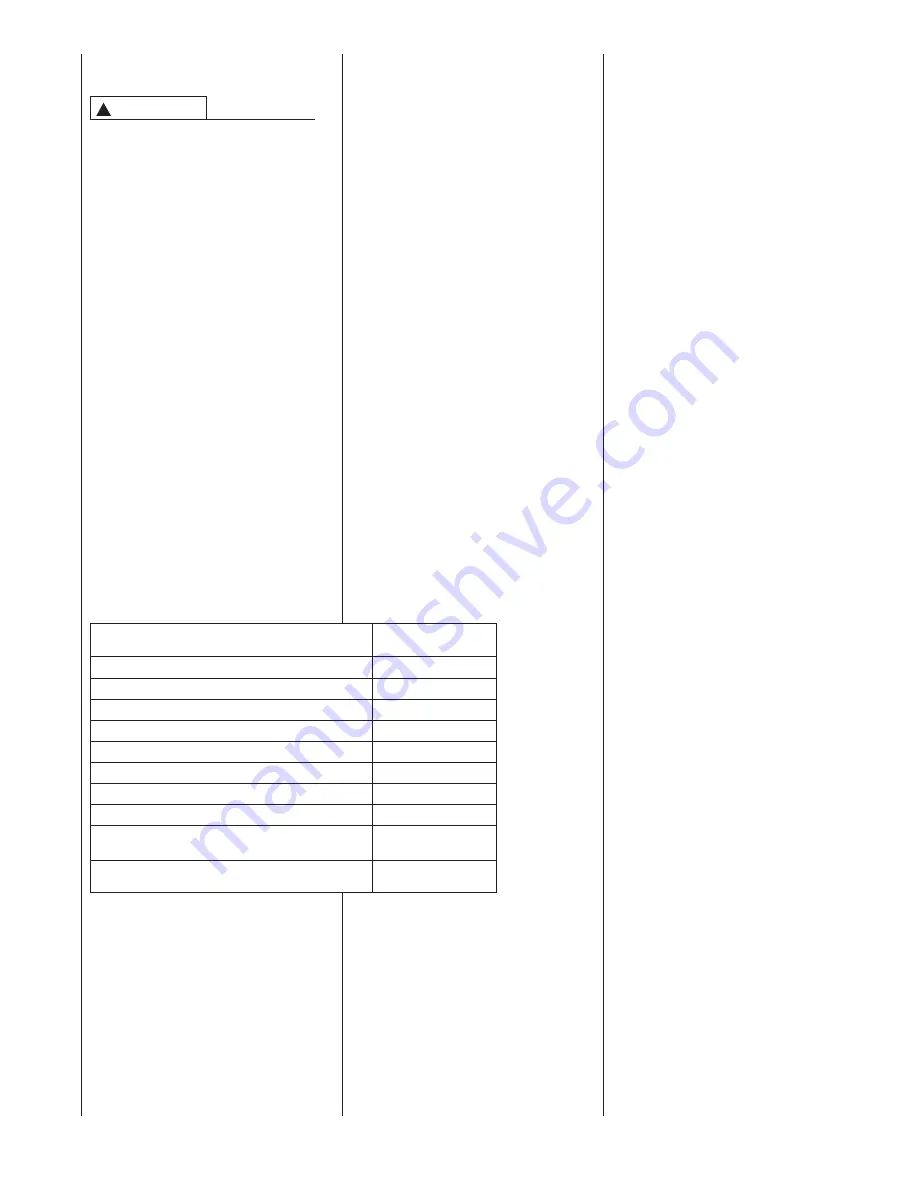

PIPE & FITTING MATERIAL

ASTM

SPECIFICATION

Schedule 40 PVC (Pipe)

D1785

Schedule 40 PVC (Cellular Core Pipe)

F891

Schedule 40 PVC (Fittings)

D2466

SDR-21PVC (Pipe)

D2241

SDR-26 PVC (Pipe)

D2241

Schedule 40 ABS Cellular Core DWV (Pipe)

F628

Schedule 40 ABS (Pipe)

D1527

Schedule 40 ABS (Fittings)

D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2661

PVC-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2665

19

Summary of Contents for RGFE

Page 92: ...92 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 93: ...93 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 94: ...94 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 95: ...95 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 96: ...96 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 97: ...97 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 98: ...98 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 99: ...99 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 102: ...102 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 103: ...103 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 104: ...104 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...

Page 105: ...105 TABLE 21 FURNACE FAULT CODES EXPANDED W DESCRIPTIONS AND SOLUTIONS CONTINUED ...