10. Service Mode

Field Service Ver. 1.0 Jun. 2008

152

Adjustment / Setting

10.3.3

Printer Area

A. Leading Edge Adjustment

Functions

• To change and adjust the position to start printing in sub scan direction per paper

type or per front or back page on the tray 1.

(To adjust the timing where paper is sent out from the timing roller)

Use

• The PH unit has been replaced.

• The paper type has been changed.

• The image on the copy deviates in the sub scan direction.

• A faint image occurs on the leading edge of the image.

• This setting can be made independently for plain paper, thick 1, thick 2, thick 3, OHP

film, and envelopes.

Adjustment

Specification

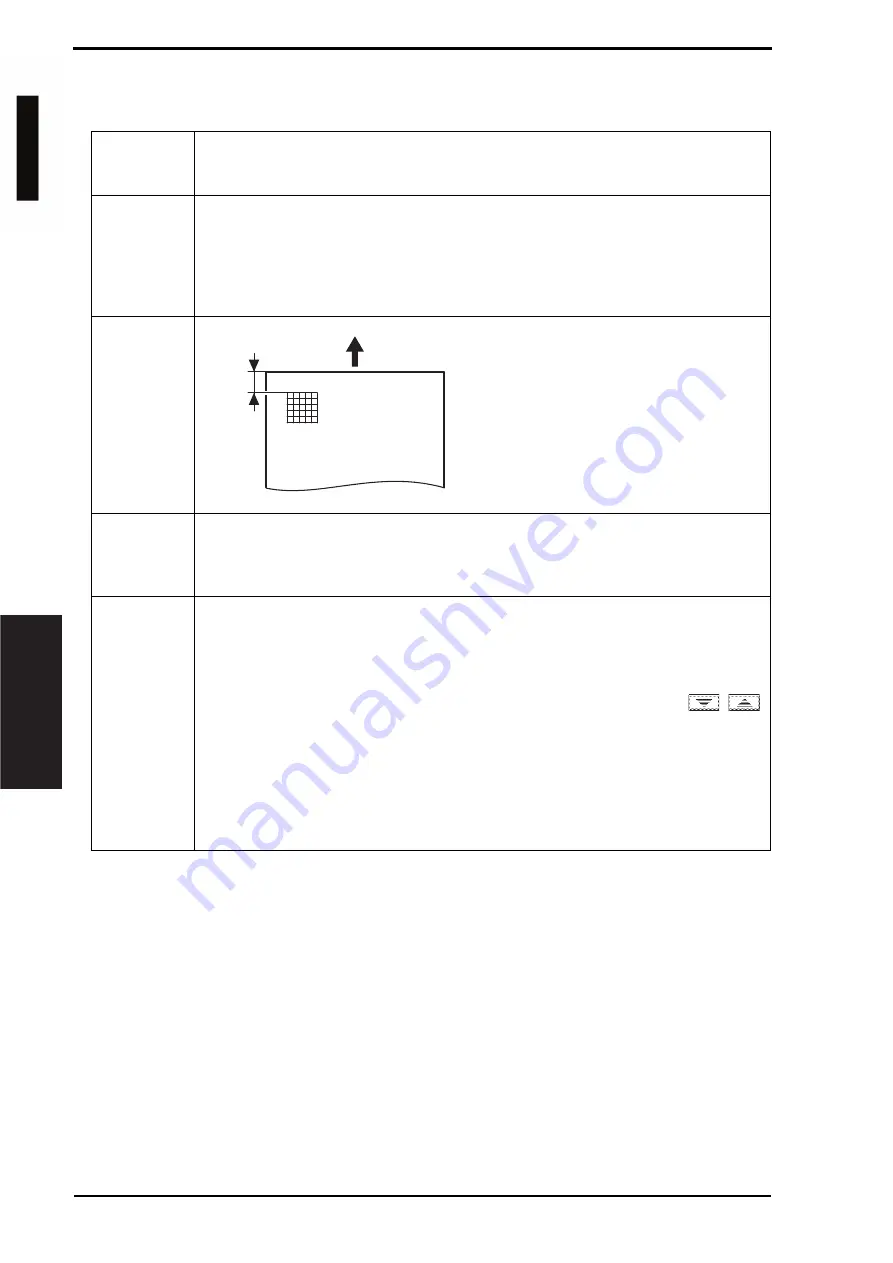

Width A on the test pattern produced should

fall within the following range.

Specifications: 4.2

r

0.5 mm

Setting range: -3.0 mm to +3.0 mm

(in 0.2 mm increments)

Adjustment

Instructions

If width A is longer than the specifications, make the setting value smaller than the cur-

rent one.

If width A is shorter than the specifications, make the setting value greater than the cur-

rent one.

Setting/

Procedure

1.

Place A3 or 11 x 17 paper on the tray1.

2.

Call the Service Mode to the screen.

3.

Touch [Machine Adjustment]

o

[Printer Area]

o

[Leading Edge Adjustment].

4.

Press the Start key to let the machine produce a test pattern.

5.

Check the dimension of width A on the test pattern.

6.

If width A falls outside the specified range, change the setting using the

/

keys.

7.

Press the Start key to let the machine produce a test pattern.

8.

Check the dimension of width A on the test pattern.

9.

If width A is outside the specified range, change the setting again and make a check

again.

10.

If width A falls within the specified range, touch [OK].

11.

Following the same procedure, adjust for thick 1 to 3, OHP film, and envelope.

A00JF3C504DA

Width A

d-Color MF201

Service Manual Y109660-1