EN

English –

3

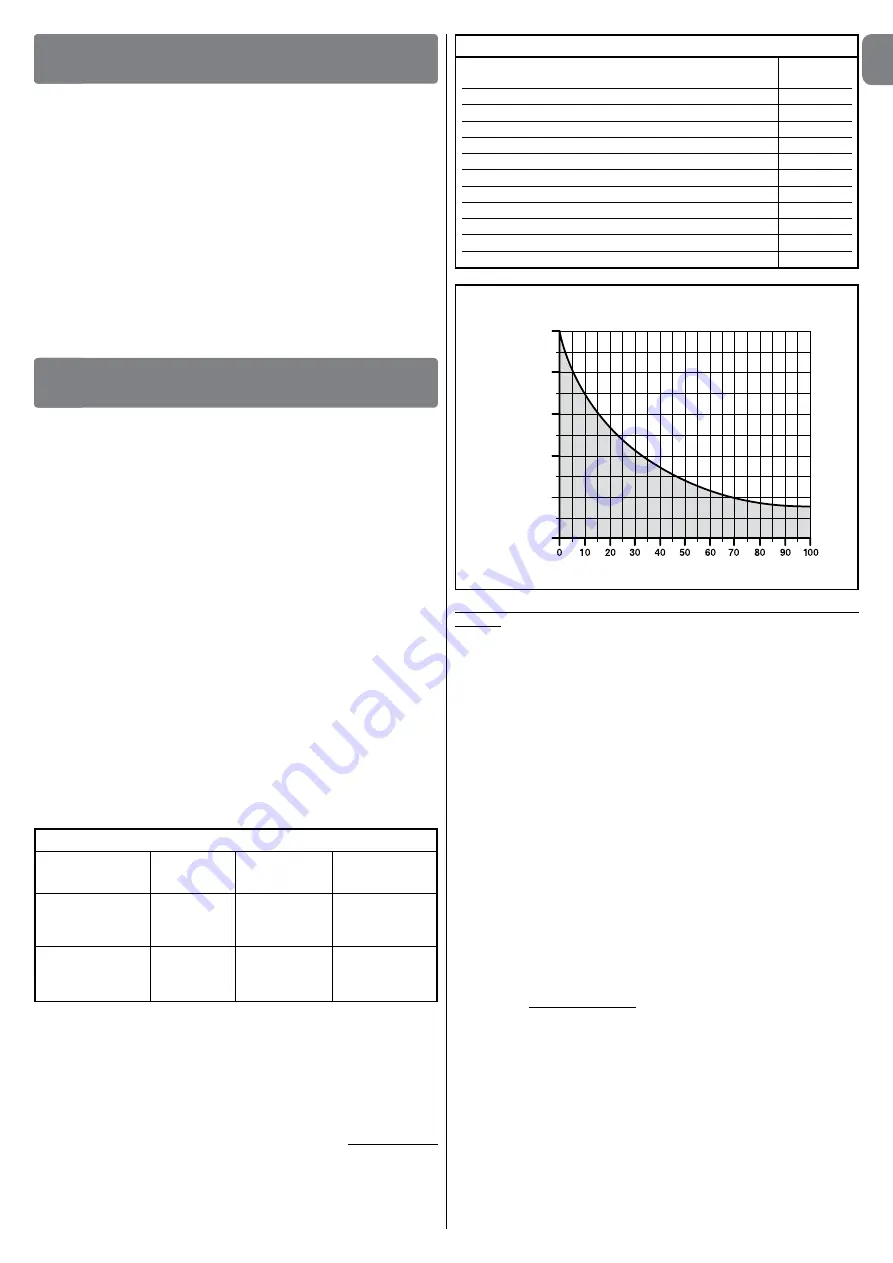

Example of calculating lifetime of road barrier S4BAR (refer to Table 2 and

Graph 1):

S4BAR with lights XBA4 (severity index of 15%) - Presence of saline mist (severity

index of 10%):

Total severity index = 25%

The estimated durability is approx. 240,000 manoeuvre cycles.

3.3 - Typical system

Fig. 3

shows the components in the product pack:

[

a

] - road barrier with built-in control unit

[

b

] - pole support

[

c

] - pole plug

[

d

] - 2 pole joining brackets

[

e

] - metal hardware (screws, washers, etc . keys for manual locking and release

of the pole)

[

f

] - fixing bolts

[

g

] - photocell box

[

h

] - foundation plate

Fig. 1

shows an example of an automation system set up with

Nice

compo-

nents . With reference to the typical standard layout in

fig. 1

, locate the approxi-

mate position for installation of each component envisaged in the system .

CAUTION! – In general, position the ends of the ducting used for elec-

trical cables in the vicinity of the points envisaged for fixture of the

various components. Note:

The ducting serves to protect electric cables and

prevent accidental damage, such as in the case of impact .

The barrier is factory set for the closing manoeuvre to the left

; in this

phase, it is important to decide whether the opening direction of the pole is to

be inverted .

If Closure to the right is required, see paragraph 3.3.1.

Prepare the electrical cables needed for your system, referring to

fig. 1

and

“

Table 3 - Technical specifications of electrical cables

” .

3.1 - Preliminary checks for installation

Before proceeding with installation, check the condition of the product compo-

nents, suitability of the selected model and conditions of the intended installa-

tion environment .

• Ensure that all material used is in perfect condition and suitable for use .

• Ensure that all product application limits can be observed (see paragraph

3 .2) .

• Ensure that the selected installation environment is compatible with the over-

all dimensions of the product (

fig. 2

) .

• Ensure that the selected surfaces for barrier installation are solid and guaran-

tee a stable fixture.

• Make sure that the fixing zone is not subject to flooding. If necessary, mount

the barrier raised from the ground .

• Ensure that the space around the barrier enables easy and safe completion

of manual manoeuvres .

• Ensure that there are no obstacles along the pole trajectory which prevent the

opening and closing manoeuvres .

• Ensure that each device to be installed is in a sheltered location and pro-

tected against the risk of accidental impact .

3.2 - Product application limit

Before installing the product, ensure that all values specified in the chapter

“Technical product specifications” and maximum cycle frequency as stated in

Table 1

are compatible with the intended use .

– Ensure that the estimated durability (see paragraph 3 .2 .1) is compatible with

the intended use .

– Ensure that all limits, conditions and warnings in this manual can be

observed .

3.2.1 - Product durability

The lifetime is the average economic duration of the product . The value of life-

time is strongly influenced by the intensity of the manoeuvres, i.e. the sum of all

factors that contribute to product wear (see

Table 2

) .

To estimate the lifetime of your automation, proceed as follows:

01.

Add the values of the items in

Table 2

regarding the system conditions;

02.

In

Graph 1

from the value obtained above, trace vertical line until it inter-

sects the curve; from this point trace a horizontal line until it intersects the

line of the “manoeuvre cycles” . The obtained value is the estimated lifetime

of your product .

The lifetime values specified in the graph are only obtainable if the maintenance

schedule is strictly observed (see chapter “Maintenance schedule”) . The esti-

mation of lifetime is made on the basis of design calculations and the results of

tests performed on prototypes . As it is only an estimation, it does not represent

any form of guarantee on the effective lifetime of the product .

INSTALLATION

3

S4BAR is an electromechanical road barrier for residential use; it controls ope-

ning and closing of a road transit point with widths up to 3 metres .

CAUTION! – Any uses other than those specified herein or in environ-

mental conditions other than as stated in this manual are to be consid-

ered improper and are strictly prohibited!

S4BAR is an electromechanical gearmotor with a 24 V motor, with optional

flashing light signal (XBA7) and electric limit switch system. The control unit is

set up for connected to devices belonging to the Nice Opera system and con-

nection to the solar power system “Solemyo” (see paragraph 4 .10 .3) .

S4BAR runs on electric energy and in the event of a power failure the pole can

be released and moved manually . Alternatively the buffer battery model PS124

can be used (optional accessory - see paragraph 4 .10 .2), which guarantees a

number of automation manoeuvres in the first few hours of power failure. To

prolong this period or extend the number of manoeuvres, the Stand by function

should be enabled (see table 6) .

S4BAR is also designed for installation of the pole lights, mod. XBA4 (acces-

sory - see paragraph 4 .8) .

PRODUCT DESCRIPTION

AND INTENDED USE

2

100.000

200.000

300.000

400.000

500.000

GRAPH 1

Severity index (%)

Manouvre cycles

Product Type

S4BAR with XBA19

pole, impact protec-

tion rubber XBA13,

without accessories

S4BAR with XBA19

pole, impact protec-

tion rubber XBA13

and lights mod. XBA4

Maximum

speed

V5

V4

Maximum work

cycles per hour

100

80

Maximum

consecutive

work cycles

50

40

TABLE 1

Severity

Index

Pole with lights mod. XBA4

15 %

Ambient temperature above 40°C or below 0°C

15 %

Presence of dust or sand

10 %

Presence of saline mist

10 %

Interruption of manoeuvre via Foto > 10%

15 %

Interruption of manoeuvre via Alt > 10%

25 %

Force equal to 5 or 6

10 %

Force equal to 7 or 8

10 %

V3 and V4 speed

5 %

Speed V5

20 %

TABLE 2

Summary of Contents for S4BAR

Page 2: ......

Page 20: ......

Page 40: ......

Page 60: ......

Page 80: ......

Page 100: ......

Page 120: ......

Page 140: ......

Page 143: ...I I 1 A B C B 330 mm 2 179 5 mm 1146 mm 826 mm 4000 mm 3 b a d e f g h c...

Page 144: ...II II 5 A B C 1 2 4...

Page 145: ...III III 9 10 90 6 A C B 7 8 B A...

Page 146: ...IV IV 14 A B 15 A B 11 A B 12 13 A B...

Page 147: ...V V 16 A B 17 18...

Page 148: ...VI VI 20 180 21 C C A B 1cm 1cm 19 A C B...

Page 149: ...VII VII 22 23 26 L N 24 1 2 25...

Page 151: ...IX 30 A A B STOP 31 A B...

Page 152: ...X 32 A B C D STOP 33 A B 34...

Page 154: ...XII 300 200 700 500 39 300 200 700 500 150 40 41...

Page 155: ...a c d e b F2 F1 42 43 XIII...

Page 156: ...XIV 44 O pe n L1 L2 L3 L4 L5 L6 L7 L8 St op Se t Cl os e Fuse 1AT 45 f g...

Page 157: ......

Page 158: ......

Page 159: ......