EN

12

– English

8.3 - Adding or removing devices

New devices can be added at any time, connected to the BlueBus and Stop

input or those present can be deleted as required . To do this, proceed as fol-

lows:

01.

Press and hold down “

s

“ and “

Set

” keys at the same time;

02.

Release the buttons when

L1

and

L2

LED’s start flashing very quickly (after

approx. 3 s);

03.

Wait a few seconds for the control unit to finish connected device self-

learning;

04.

At the end of this phase, the

STOP

led must remain lit, while leds

L1

and

L2

turn off (where relevant leds L3 and L4 start flashing).

After performing this procedure, the automation testing procedure must be

performed as described in chapter 5 .1 .

8.3.1 - Bluebus Inlet

This Bluebus system allows device connections to be made using just 2 con-

ductors for both the electricity supply and the communication signals . All devic-

es are connected in parallel on the same 2 Bluebus wires, without the need

to observe polarity; Each device is individually recognized because a unique

address is assigned to it during installation . Bluebus can be used to connect

the following: photocells, safety devices, control devices such as key-boards

and readers for transponder cards, indicator lamps, etc . The control unit recog-

nises each one of the devices connected during the self-learning phase and is

able to detect all possible faults in maximum safety. For this reason each time a

device is connected to or removed from Bluebus the self-learning phase must

be repeated, as described in paragraph 4 .4 .

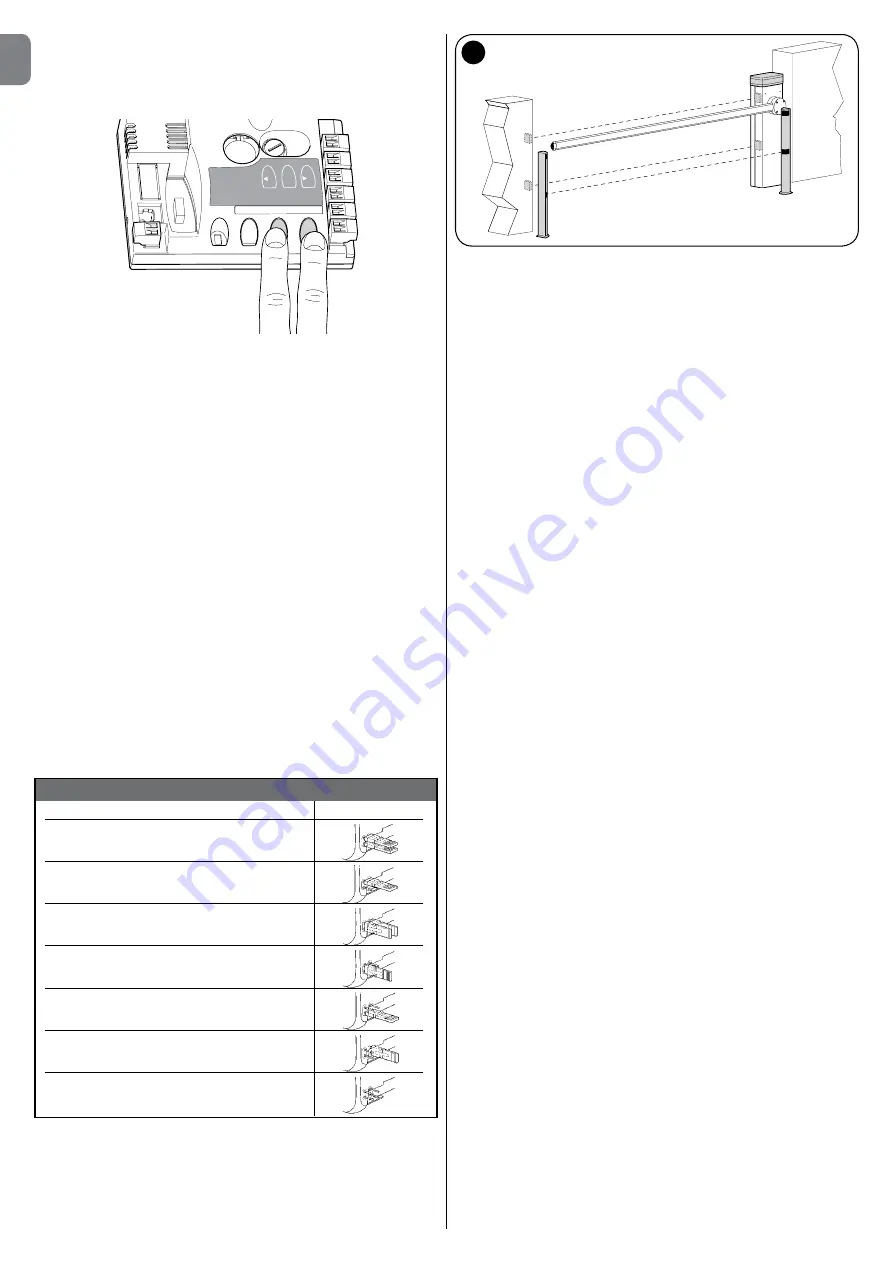

8.3.2 - Photocells

The Bluebus system enables the control unit to recognise the photocells, con-

trol routing of the relative jumpers (see

Table 13

) and enables assignment of

the correct value for the obstacle detection function . The routing operation is

performed both on TX and RX, positioning the jumpers in the same way with a

check that there are no pairs of photocells with the same address .

The photocells can be installed as shown in

fig. A

.

Important

– After installing

or removing the photocells, the device learning phase must be performed, as

described in paragraph 4 .4 .

It is possible to install the TX or RX photocell inside the caisson of the barrier, in

the space provided (

fig. 43

) .

To install the photocell, proceed as follows:

01.

Extract the board of the photocell from its box by prising it out with a slot-

ted tip screwdriver (

fig. 43-a

) .

IMPORTANT!

- Do not damage the electric

components inside;

02.

Open the box prepared for the photocells, present in the accessory box (

fig.

47-b

);

03.

Block the board on the bottom of the box (

fig. 43-c

);

04.

Pierce the rubber arranged for the passage of the electric cable (

fig. 43-d

);

05.

Route the electric cable and connect it to the terminal of the photocell (

fig.

43-e

);

06.

Close the bottom of the box with the cover, taking care to block the rubber

in its seat (

fig. 43-f

);

07.

Hook the box on the lens on the side of the caisson by making it slide from

top to bottom (

fig. 43-g

) .

8.3.3 - MOTB digital selector and proximity reader for MOMB

transponder cards

The Bluebus system enables connection of up to 4 MOTB digital selectors or 4

MOMB transponder badge readers .

MOTB enables control of the automation, by entering one of the memorised

numerical codes on the keypad .

MOMB enables control of the automation by simply placing the memorised

transponder bade close to the automation .

These devices have an individual code, which is recognised and memorised

by the control unit during the phase for learning all connected devices (see

paragraph 4 .4) .

This prevents an fraudulent attempts to replace a device or use of the automa-

tion by unauthorised persons . For further information, refer to the instruction

manual for MOTB and MOMB .

8.3.4 - STOP Input

The Stop input causes the manoeuvre to stop immediately followed by a short

reverse run . Devices with normally open NO or normally closed NC contact

outputs, optical devices (Opto Sensors), or devices with 8 .2 k

Ω

constant resi-

stance output such as sensitive edges can be connected to this input . The

control unit, during the learning phase, recognises the type of device con-

nected and activates a STOP command when any variation in the learnt status

occurs . When set accordingly, more than one device can be connected to the

STOP input, also different from one another;

• Several NO devices can be connected in parallel, with no limit to the number;

• Several NO devices can be connected in series, with no limit to the number;

• Two devices with an 8 .2K

Ω

constant resistance output can be connected

in parallel; multiple devices must be connected “in cascade” with a single

8 .2K

Ω

termination resistance;

• An NO and NC type combination is also possible, placing the 2 contacts in

parallel . In this case, a 8 .2 K

Ω

resistance must be placed in series with the

NC contact; this also enables the combination of 3 devices: NO, NC and 8 .2

K

Ω

.

Caution

– If the STOP input is used to connect devices with safety functions,

only the devices with a constant resistance of 8,2 K

Ω

or OPTO SENSOR opti-

cal devices guarantee adeguate safety levels against faults .

For connection of an optical device type OPTO SENSOR make the connections

as shown in

fig. 44

. The maximum current provided on the 12 Vdc line is 40 mA.

8.4 - Diagnostics

Some devices are able to emit signals that serve to recognise their state of

operation or possible faults .

8.4.1 - Signals of control unit

The leds of the terminals and the keys on the control unit (

fig. 45

) emit special

signals both to indicate normal operation and possible faults .

Tables 14

and

15

describe the cause and solution for each type of signal .

O

p

en

St

op

Se

t

Clo

se

Fuse 1AT

L1

L2

L3

L4

L5

L6

L7

L8

TABLE 13 - PHOTOCELL ADDRESSES

Photocell Jumpers

PHOTO

Photocell h = 50

activated on closure

PHOTO II

Photocell h = 100

activated on closure

PHOTO 1

Photocell h = 50

activated on closure

PHOTO 1 II

(

*

)

Photocell h = 100

activated on closure

PHOTO 2

Photocell activated on opening

(inverts on closing)

PHOTO 2 II

Photocell activated on opening

(inverts on closing)

PHOTO 3

Single photocell activated on opening

and closing

F

F

F 1 II

F 1 II

F II

F II

F 1

F 1

A

Summary of Contents for S4BAR

Page 2: ......

Page 20: ......

Page 40: ......

Page 60: ......

Page 80: ......

Page 100: ......

Page 120: ......

Page 140: ......

Page 143: ...I I 1 A B C B 330 mm 2 179 5 mm 1146 mm 826 mm 4000 mm 3 b a d e f g h c...

Page 144: ...II II 5 A B C 1 2 4...

Page 145: ...III III 9 10 90 6 A C B 7 8 B A...

Page 146: ...IV IV 14 A B 15 A B 11 A B 12 13 A B...

Page 147: ...V V 16 A B 17 18...

Page 148: ...VI VI 20 180 21 C C A B 1cm 1cm 19 A C B...

Page 149: ...VII VII 22 23 26 L N 24 1 2 25...

Page 151: ...IX 30 A A B STOP 31 A B...

Page 152: ...X 32 A B C D STOP 33 A B 34...

Page 154: ...XII 300 200 700 500 39 300 200 700 500 150 40 41...

Page 155: ...a c d e b F2 F1 42 43 XIII...

Page 156: ...XIV 44 O pe n L1 L2 L3 L4 L5 L6 L7 L8 St op Se t Cl os e Fuse 1AT 45 f g...

Page 157: ......

Page 158: ......

Page 159: ......