4-6

Maintenance MENUs at-a-glance

Item

Set value

Meaning

Station

For carrying out maintenance on the carriage and station periphery.

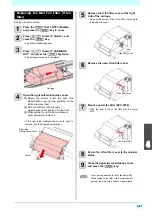

Carriage Out

(

Moves the carriage out, for carrying out cleaning of the cap periphery,

head, wipers, etc.

Nozzle Wash

(

1 to 15min

Soaks the nozzle surfaces in maintenance cleaning fluid, for carrying

out recovery from nozzle missing or bent.

Pump Tube Wash

(

Executes washing of the suction pump tubes.

Custody Wash

(

1 to 15min

Carried out when the machine is going to be out of use for an extended

period. Washes the nozzles and tubes beforehand, to keep the

machine in fine condition.

Replace Wiper

(

Used when replacing the wiper. If the wiper is replaced, the number of

times the wiper was used that is managed in this device is reset.

Nozzle Recovery

(

For printing using another nozzle, if nozzle wash and so forth fail to effect recovery from nozzle missing, etc.

Used to print a pattern and to check and/or register clogged nozzles.

ENTRY

Registers the faulty nozzle identified by “PRINT”.

CLEAR

Resets a registered faulty nozzle.

CHECK

Checks recoverable printable conditions.

Auto Maint.

(

For having the various maintenance functions executed automatically. Set the execution interval for each

maintenance function.

Refresh

OFF/Lv.1/Lv.2/

Lv.3

For setting the activation interval for refresh.

Cleaning

OFF/Lv.1/Lv.2/

Lv.3

For setting the activation interval for head cleaning.

Sub Tank (

Used to charge ink and to solve the problems including ink errors and

nozzle missing .

Air PG (

Removes any air inside the print head causing poor discharge.

Replace Ink Tank (

Used to replace an ink tank and to reset the ink charge information.

Summary of Contents for SIJ-320UV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Page 14: ...xiii Warning labels ...

Page 28: ...1 14 Chapter 1 Before Use ...

Page 98: ...4 26 ...

Page 116: ...5 18 Chapter 5 Troubleshooting ...

Page 122: ...Chapter 6 Appendix 6 6 ...