3-4

Chapter 3 Setup

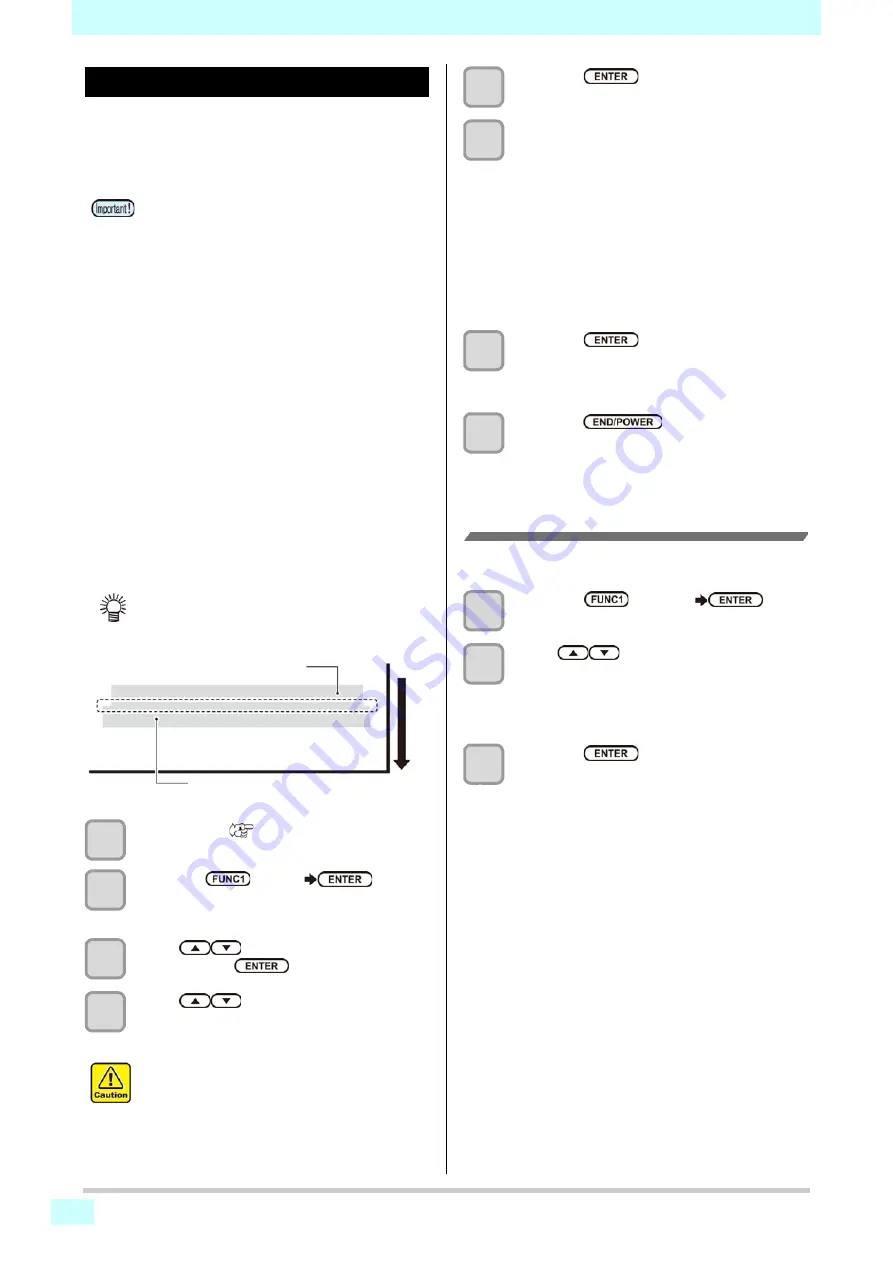

Setting of Media Correction

Correct the media feed amount to match the type of

media you are using.

If the correction value is not appropriate, stripes may

appear on the printed image, thus resulting in a poor

printing.

A pattern for media correction is printed and a media-

feeding rate is corrected.

1

Set a media. (

2

Press the

(MENU)

key in

Local.

• Setup MENU appears.

3

Press

to select “Feed Comp.” ,

and press the

key.

4

Press

to enter resolution.

• Here enter the resolution in the scanning direction

(Y direction) of the media.

5

Press the

key twice to print the

correction pattern.

6

Check the correction pattern and enter a

correction value.

• A screen for entering the correction value

appears.

•

Enter a correction value in "+"

:

The boundary between the two bands is widened.

•

Enter a correction value in "-"

:

The boundary between the two bands is

narrowed.

• When you change the correction value by "25",

the width of the boundary changes by about 0.1

mm.

7

Press the

key.

• Print a correction pattern again and check it.

• When media correction is needed, perform the

operation in Step 6 to make correction.

8

Press the

key several times to

end the setting.

Correcting Media-feeding during

Printing

A media-feeding rate can be corrected even in the remote

mode or when image data is printed.

1

Press the

(ADJUST)

key in

the Remote.

2

Press

to enter a corrected

feeding rate.

• Corrected feeding rate: -9999 to 9999

• The value entered here is reflected in the

corrected feeding rate soon.

3

Press the

key twice.

• key. The changed value is registered.

• When you press the [ENTER] key instead of the

[END/POWER] key, the value entered here will be

valid temporarily.(When you perform media

detection again or turn the power OFF, the

correction value is cleared.)

• Be sure to perform feed correction each time

before printing. The media feed amount may vary,

depending on the remaining amount of the roll

media.

• If use by setting the media to Narrow roll holder,

rewind the roll media by hand and set without

slack. There may not be accurate to correct the

feed amount.

• On completion of [MEDIA COMP.] during use of a

roll media, the media returns to the printing origin.

When a media is set on the narrow roll holder,

slack occurs in the roll media on the backside of

this machine.

Before printing, take up the slack in the roll media

by hand; a loose roll media can result in an inferior

image quality.

• When printing with a take-up device, set the media

first and then perform media correction.

• When printing without using the take-up device,

feed the media until the media reaches the floor

before performing the correction. Otherwise, the

feed amount may not be adjusted normally.

• Two bands are printed in the correction pattern.

• Make adjustment so that an even color density is

obtained in the boundary between the two bands.

• Enter a resolution matching the data printed

usually. This machine changes the media feeding

method, depending on the resolution. If you enter

a resolution inconsistent with actual printing, it

may result in an inappropriate feed amount.

Second band

First band

Media advance dir

ection

Summary of Contents for SIJ-320UV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Page 14: ...xiii Warning labels ...

Page 28: ...1 14 Chapter 1 Before Use ...

Page 98: ...4 26 ...

Page 116: ...5 18 Chapter 5 Troubleshooting ...

Page 122: ...Chapter 6 Appendix 6 6 ...