5-4

Chapter 5 Troubleshooting

Ink tank warning appears

If an ink tank trouble is detected, a warning message

appears.

None of printing, cleaning and all the other operations that

use ink is available.

If an abnormality occurs, perform the following

procedures:

• Check the ink amount in the ink tank and if the ink amount

is not enough, add ink.

Displaying the description of ink bottle

trouble

The contents of ink bottle error are confirmable by the

following operations.

1

Press the

key in Local.

If an error related to the Sub Tank

occurs (Error 618 to 61b)

The Error 618 to 61b are related to the sub tank.

Execute following procedures when an error about sub

tank occurs, or when the nozzle is not unclogged after

cleaning.

1

Press the

(MENU)

in Local.

2

Press

to select “Maintenance”,

and press the

key.

• Maintenance MENU appears.

3

Press

to select “Sub Tank”, and

press the

key.

4

Press the

key.

• Discharge the ink in the sub tank, and charge ink

into the tank.

• When the charging into the sub tank is completed,

the air purging selection screen appears.

5

Press

to select action, and press

the

key.

• Select “Execute” to move to the air purge menu.

• Select “Completed” to perform head cleaning.

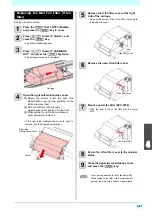

If nozzle missing due to color mixture

of ink or aeration

If nozzle missing occurs due to color mixture of ink in the

head or aeration, push ink or air in the head out from the

port.

1

Press the

(MENU)

in Local.

2

Press

to select “Maintenance”,

and press the

key.

• Maintenance MENU appears.

3

Press

to select “Air PG”, and

press the

key.

• The station moves downward to the empty

absorption position.

• When it lowers to the empty absorption position,

“Open Cover” is displayed on the screen.

4

Open the right lower maintenance cover.

5

Open the maintenance cover before the

carriage.

6

Cover the rail part before the station with a

waste cloth etc.

• Once ink tank trouble is displayed, do not leave

the ink bottle without replacing it for a long time;

otherwise, the machine will lose the nozzle

missing prevention function.

If nozzles are clogged, the machine must be

repaired by MIMAKI's service engineer.

• Ink may drop from the nozzle during air

ventilation. An operator should not leave this

machine during air ventilation.

• After the work has been completed, attach the

removed cover as soon as possible. If you leave it

for a long time, UV light may affect ink.

• Be sure to cover the rail part before performing

the work. If ink drops on the rail part, ink will be

hardened and it may cause the operation defect.

Maintenance cover

Summary of Contents for SIJ-320UV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http mimaki com D202809 13 Original instructions ...

Page 14: ...xiii Warning labels ...

Page 28: ...1 14 Chapter 1 Before Use ...

Page 98: ...4 26 ...

Page 116: ...5 18 Chapter 5 Troubleshooting ...

Page 122: ...Chapter 6 Appendix 6 6 ...